- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming - steels and metals

Results for

Forming - steels and metals - Import export

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

PROSAW LIMITED

United Kingdom

ASM model is made of cast iron construction. ASM machines are combining the user friendly features, quality and best prices as an economical model. ASM - 3 Rolls Asymetical Plate Roll Machine Standard Details Body is made of cast iron construction Central rollers powered with electric motor, gearbox and gear drive Cone bending device Self brake main motor Upper roll is opanable by side Lower roll and back roll are with hand wheels up & down adjustable. Separate eletric control panel with foot pedal Suitable for CE, ISO 9001-2008, TSEK and TURQUM certificates ASM - 3 Rolls Asymetical Plate Roll Machine Optional Features Induction hardened rolls. Back roll with motor. Digital display.

Request for a quote

NAIDEKA, UAB

Lithuania

NAIDEKA, UAB is a client-oriented metal processing company - steel and metal stamping, bending, welding.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

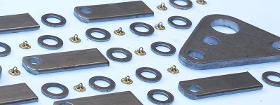

As a competent industrial partner, we produce stamped, bent-wire and formed components from stainless steel, non-ferrous metals and regular steel in a consistent quality. Dependability and flexibility characterize our performance. Our experience and technical know-how enable fast response and economical pricing. Benefit from the experience our staff have gathered with these products. We can competently process small as well as large orders. Possible material thicknesses: 0.5 to 4.5 mm. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROKVELAS, UAB

Lithuania

- External thread rolling: M8, M10, M12, W16.

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quote

MARXAM PROJECT

Poland

Machining centers and CNC turning centers allow for steel turning, metal milling, aluminum milling and the production of single details and production series with difficult and complex shapes in the highest accuracy class. Turning and milling services are the basic methods of machining various materials. However, conventional machining is time-consuming and, in addition, does not guarantee a high level of repeatability in the case of series production. Therefore, Marxam Project encourages CNC turning and milling to take place in our plant. Thanks to the use of modern machines, CNC milling services and CNC turning services ensure a high class of accuracy of the machining process.

Request for a quote

MARXAM PROJECT

Poland

Turning services and milling services are one of the basic methods of machining metal and plastic elements. A park of conventional machines maintained in the highest accuracy class allows for the precision machining service – production of precise details in high tolerance classes for both larger and smaller production series. Machining of metal materials, metal alloys or plastics is the basic method of metal processing classified as subtractive machining, which allows to obtain structural elements of specific shapes and number of details. Conventional metal turning and conventional plate milling are fundamental methods of machining – Marxam Project encourages you to use the service of professional shaping of materials, which is carried out using high-class equipment in a modern machine park. Our lathe services allow for machining plates, metal sheets, milling steel plates and many more.

Request for a quote

MARXAM PROJECT

Poland

The use of appropriate technology and high-precision machines allows us to ensure that plate rolling operations are carried out according to each customer’s request. The machines we use for rolling metal, have a very wide range of metal sheet rolling, which are intended for serial production (industrial sheet rolling), as well as for individual, single projects. The use of modern machines for bending sections allows us to provide service also during aluminum bending or sheet rolling operations of closed profiles and pipes.

Request for a quote

MARXAM PROJECT

Poland

CNC bending of sheet metal technology is the most popular method of plastic processing, allowing to obtain details of both simple and complex shapes. The use of modern press brakes allows for the maximum possible repeatability in cnc bending of the produced elements for any number of items. The modern CNC tube bending services and the automatic compensation of the deflection arrow give maximum accuracy and repeatability in 7 axes and allow you to maintain the required angles along the entire length of the bending line. An extensive tool park allows us to adapt to any customer’s technological requirements. We offer sheet metal bending services, such as tube bending, metal curving, metal sheet folding, aluminum sheet bending, bending steel and many more.

Request for a quoteResults for

Forming - steels and metals - Import exportNumber of results

12 ProductsCountries

Company type