- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filter elements

Results for

Filter elements - Import export

CIC - KLAUS CZERWONKA

Germany

electrical and optical differential pressure indicators Set pressure Maximum operating pressure

Request for a quote

SIGA FILTRATION

United Kingdom

SF-IL Inline Screen Filters Heavy duty industrial inline screen filters for coarse applications. Standard units are supplied with inline connections for easy istallation. Industrial design Range of screen sizes Hinged closure Stainless Steel Construction PN16 flange 10 bar pressure rating PED compliant F-SF Inline Bulk Transfer Filter Designed for product transfers from holding tanks to tankers. Ideal for product transfers from tankers to tanks Industrial or hygienic design Camlock couplings for quick connections Clamp closure for easy maintenance Basket in range of mesh sizes PED 10 bar -10 / 80 °C

Request for a quote

SIGA FILTRATION

United Kingdom

acuraBag Filter Bags offer a cost effective solution for high flow rate filtration. Self-aligning design of moulded collar provides hermetic sealing inside the basket. Collars are manufactured from the same material as the bag to provide excellent chemical compatibility. Available in a range of micron ratings and industry standard sizes, all acuraBag filter bags are Silicone free, come with integrated handles for easy removal and supplied individually wrapped to avoid contamination. Polyester felt material is ideal for high temperature applications.

Request for a quote

SIGA FILTRATION

United Kingdom

acuraPromelt is an absolute rated depth filter cartridge for high efficiency particulate removal from liquids. This cartridge offers exceptional performance, long service life and low pressure drop. Manufactured from 100% Polypropylene, acuraPromelt is completely free from glue and binders. acuraPure Nylon Filter cartridge for applications where PP is not suitable. acuraPEpro filter cartridges are manufactured from 100% Polyester and exhibit high temperature (up to 120°C) and chemical resistance. These cartridges provide outstanding performance in sidestream LTHW & MTHW circuits by removing scale, rust and sediment from hot water. All acuraPEpro filter cartridge come with an internal support core for additional strength in high temperature applications. FINEPleat GFP filter cartridges feature absolute rated glass fibre media with polyester support and drainage layers. Polyester construction provides thermal resistance up to 120°C and chemical resistance in fuel and chemical application

Request for a quote

SIGA FILTRATION

United Kingdom

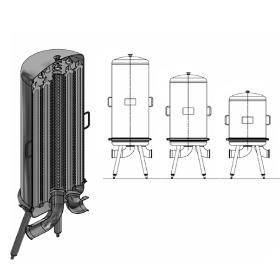

STERALine PBT Filter housings are part of our hygienic filter housing range for food, beverage, pharmaceutical, API, fine chemicals and semiconductor industry. All hygienic housings are manufactured under strict quality control in facilities that only use Stainless Steel to avoid cross contamination of materials. STERALine PBT filter housings come with optional 0.8Ra internal finish and triclamp connections. A range of optional accessories, connections and finishes available on request. STERALine GT Gas cartridge filter housings are the newest addition to our range of sanitary range. Designed and manufactured specially for gas filtration in beverage, pharmaceutical and hygienic applications, STERALine GT Series filter housings feature robust 316L Stainless Steel construction, hygienic surface finish and a free draining design which is easy to clean. STERALine Vent cartridge filter housings have been specially designed for hygienic tank vent applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIGA FILTRATION

United Kingdom

ACBB-P Big Blue Filter Housings combine durability with performance and economy. Big Blue filter Housings are available in 10″ & 20″ length and come with the option of 1″ or 1.5″ connection size. Polypropylene construction 10″ or 20″ Big Blue Cartridges Threaded closure 1″ or 1 1/2″ BSPF connections 5.8 bar 38°C PED compliant

Request for a quote

LISINE EPSTEIN COSMETICS BV

Belgium

Crème Hydratante Teintée is a moisturizing tinted day cream with beeswax, jojoba-oil, moisturizing elements and UV-filters. An intensive treatment for normal skin tending to dryness.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

STAMIXCO AG

Switzerland

The SMN Injection Molding Static Mixing Nozzle creates homogeneous mixing of polymer melt during injection. The resulting high viscous polymer melt flow is homogeneous with regard to colorant, additives and temperature. Benefits Outstanding melt flow mixing of molten polymer prior to injection results in the following benefits: Reduced spots, streaks and clouds of color Reduced colorant usage (10% - 40) Narrower part tolerance Reduced reject rates Less part distortion Less weight variation Improved part quality when using regrind material Shorter cycle time Improved melt flow Increase regrind ratio with consistent product quality Rapid nozzle heat-up Normal Pay-back period of 2-3 months Filter for Injection Molding Static Mixing Nozzle (Type SMF) The optional SMF Filter is installed inside of the Static Mixing Nozzle to protect the hot runner system and mold when processing regrind materials by avoiding clogging and/or damage with debris carried along with the feed pellets. Grid Protection Disk for Mixing Elements (Type GPD) The optional GPD Grid Protection Disk is installed inside of the Static Mixing Nozzle upstream the first mixing element. During the start-up operation it avoids a possible so called “cold-start” damage of the mixing element grid by plugs of not completely molten and thus partly solid polymer plugs originating from the transition part between the end of the barrel and the Static Mixing Nozzle Benefits & Function The SMF Filter is designed to be used with the SMN Injection Molding Mixing Nozzle. The purpose and functionality of the SMF filter are numerous: Protects hot runner system and mold by avoiding clogging and/or damage caused my metal pieces accidentally introduced with the feed pellets to the injection molding machine (staples, metal chips, paper clips, etc). Retains semi-molten polymer pellets until melted for incorporation into the polymer melt For customers with poor thermal control systems, the SMF Filter acts as an upstream breaker-plate to prevent “cold-start” crushing of the mixing elements. Designed to retrofit into the SMN Injection Molding Mixing Nozzle without nozzle modification O.D. of SMF Filter = O.D. of SMN Mixing Elements Length of one (1) SMF Filter = Length of two (2) SMN Mixing Elements O.D of GPD = O.D. of SNM Mixing Elements Length of one (1) GPD = Length of one (1) SNM Mixing Element

Request for a quoteResults for

Filter elements - Import exportNumber of results

10 ProductsCompany type