- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drives- electrical

Results for

Drives- electrical - Import export

IGUS® GMBH

Germany

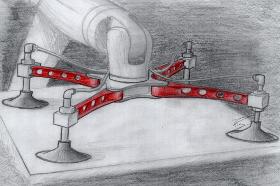

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

ARINKO BAUTZEN GMBH

Germany

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

SMART, COMPACT MULTI-PROCESS Lincoln Electric's Weld Pak 2000 is a complete multi-process continuous voltage arc welding machine ideal for welding thin sheets and repair and maintenance work. This machine is a perfect tool for light steel applications and is mobile, meaning the operator can easily move this MIG welding machine to any location in the workshop. Weld Pak 2000 is recommended for MIG/MAG applications, for arc welding with Innershield gas-free flux-cored core and applications with Rutile and Basic electrodes. This machine is designed to feed wire from 0.6 mm to 1.1 mm (steel, stainless steel and flux cored) on B300 and S200 coils. High quality welding performance that depends on a quality wire drive system. Lincoln Electric has equipped the Weld PAK with a professional feeder with large rollers. The Weld Pak 2000 is designed to meet Lincoln performance and reliability standards. : Compact design with a standard

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NHM LIMITED

Ukraine

SPECIFICATION PRODUCTIVITY1500 pouches/hour FILLING RANGE200-1000 ml POWER SUPPLY, MAX220 V, 50 Hz COMPRESSED AIR PRESSURE5 kg/cm2 AIR CONSUMPTION~ 0.2 m3/hour @4 bar PACKAGING MATERIAL1/2/3-layered polyethylene film with black internal layer; thickness – 70-90 microns, width – 320 mm FILLING ACCURACY± 0,5-1% [depending upon bulk density of product, constant product availability in the product tank (for liquids), proper maintenance] OVERALL DIMENSIONS , (WxLxH)670 x 790 x 2570 mm WEIGHT, NET~ 450 kg MACHINE CONSTRUCTION All components are mounted on a single frame. All parts in contact with the product are made from stainless steel AISI 304 . The exterior panels are made of stainless steel AISI 202. Mechanical drive. Protective and hygienic front door. Basic Elements: Film unwinding is provided by rubberized shaft with electric drive and operated by inductive sensors Ultra-violet lamp for film sterilization Liquid Filler CIP connector

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

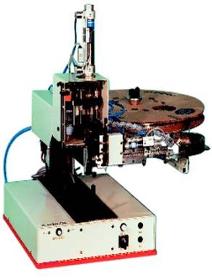

TYP A 040/B Solder lug inserting with tape feeder Description The solder lug inserting device Type A 040 B, was constructed for a mechanised insertion of solder lugs. Fixed cycles of less than one second are within easy reach. A Foot pedal controls the individual stroke sequence. The taped solder lugs are automatically fed into the machine. Therefore, no additional material and wage costs for threading the solder lugs on leads will arise. The device is able to process all kind of taped solder lugs with standard forms. After a slight alternation, solder lug strips, which deviate from standard, can also be processed. To do this, you simply have to replace the insertion head with stripe guide and the cutting tool, which is fast and easy to do. All driving elements and electrical switches belong to the main machine and therefore, they do not have to be moved. The bearing pedestal for the material bin can hold coils up to 500 mm ø. An adjustable conical ring centres the coil on the bearing pedestal. Working with this device is very easy and save. Components

Request for a quoteResults for

Drives- electrical - Import exportNumber of results

8 ProductsCountries

Company type