- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- custom-cut

Results for

Custom-cut - Import export

NORELEM FRANCE

France

Steel 1.0037. Aluminium EN AW-6060. Version: Steel electro zinc-plated. Aluminium anodised. Note: The machined tolerances of these round and square tubes are individually matched to the tube clamping system. *Square aluminium size 10x10 are only available as solid bars. On request: - Custom cut length (L max. 5000 mm) - Stainless steel tube (L max. 3000 mm)

Request for a quote

CNC CREATIONS

United Kingdom

At CNC Creations we can supply high quality Dibond panels in a range of sizes, colours and finishes ready to be cut, shaped and finished to your requirements. As we’re located centrally in the country it’s also easy for us to deliver your finished CNC Dibond project wherever it’s needed anywhere in the UK For hardwearing signage and displays with high visual impact, Dibond is one of the most cost-effective and versatile materials you can use, and CNC Creations can custom cut, shape and finish Dibond for you with outstanding results.

Request for a quote

MARXAM PROJECT

Poland

The technology of laser cutting pipes and profiles has two main advantages compared to traditional processing methods: - tube cutting allows for a significant reduction in the costs of preparing sections for further production; - laser tube cutting services allow the use of many new construction and technological solutions. Our 3D laser profile cutting and 3D welding systems are ideal for machining 2D and 3D components or tubes. The ability to flexibly switch between cutting, welding and laser cladding allows for maximum production efficiency, and the dynamic, optical cutting system significantly reduces processing time. An additional advantage of industrial laser cutting for serial production is the possibility of working in a rotational mode – during the operation of the machine, it is possible to unload and load new elements for processing.

Request for a quote

MARXAM PROJECT

Poland

Laser cut companies have become quite prominent in metalworking industries. Choosing Marxam Project, you are choosing a reliable partner with decades of experience. Sheet metal laser cutting is a technology that allows you to quickly and cheaply obtain an element of any complex shape from various types of flat sheets. The undoubted advantages of laser cutting are: - cutting laser offers freedom of shapes, limited only by the properties of a material; - cutting metal with repeatability of details at the level of 100%; - for given types of materials and their thickness, the laser cut surface is of a quality that allows the elimination of the finishing process; - the best possible use of the surface of the material – thanks to the use of appropriate computer programs, with our laser cutting services, we obtain a large percentage of sheet metal use, and we can properly optimize the production process; - it allows to reduce the effect of heat on the deformation of the cut material

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply fully automatic EPS cutting lines, as well as the customized compact cutting machines. Optional scrap collection system and automatic wire adjustment units are available. For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAXON MOTOR AG

Switzerland

When that extra dose of torque is necessary. Our planetary, spur and special gearheads perfectly compliment our motors. When performance is required at high torque levels and correspondingly low speeds, maxon precision gearheads are in their element. In addition to a wide standard range of spur and planetary gearheads, maxon motor also excels in providing customized solutions, tailored to the customer's requirements. Cutting-edge materials and manufacturing processes are used (e.g. CIM/MIM). The gearheads are adapted to the desired motors on site in the supplying plant, further improving the gearhead performance. maxon spur gearheads Spur gearheads are suitable for low torques. The gearheads consist of one or more stages. One stage represents the pairing of two cogwheels. The first toothed gear (pinion) is mounted directly on the motor shaft. The bearing of the output shaft is usually made of sintered materials. Attractively priced Output torque of up to 2 Nm Reduction ratio of 6:1 to 5752:1 Low noise level High efficiency maxon planetary gearhead Planetary gearheads are suitable for transferring high torque. The larger gearheads are normally equipped with ball bearings at the gearhead output. Torque up to 180 Nm Reduction ratio of 4:1 to 6285:1 High power in a small space maxon Koaxdrive The quiet maxon Koaxdrive gearhead combines worm and planetary gearheads. The signature characteristic of the drive is its unusually quiet running, even under heavy loads. Quiet High reduction ratio in the first stage Combined with maxon EC motors, ideal for medical technology. maxon spindle drive Spindle drives transfer the power generated by the motor into linear feed rate and feed force. The output shaft's bearings can absorb highest axial loads. Compact design due to direct integration of the spindle Comprises planetary gearhead with radial and axial bearings Designed for high forces and linear feed rates Wide range of spindles to suite any applicationHigh power in a compact design with torques up to 120 Nm.

Request for a quote

MAXON MOTOR AG

Switzerland

When that extra dose of torque is necessary. Our planetary, spur and special gearheads perfectly compliment our motors. When performance is required at high torque levels and correspondingly low speeds, maxon precision gearheads are in their element. In addition to a wide standard range of spur and planetary gearheads, maxon motor also excels in providing customized solutions, tailored to the customer's requirements. Cutting-edge materials and manufacturing processes are used (e.g. CIM/MIM). The gearheads are adapted to the desired motors on site in the supplying plant, further improving the gearhead performance. maxon spur gearheads Spur gearheads are suitable for low torques. The gearheads consist of one or more stages. One stage represents the pairing of two cogwheels. The first toothed gear (pinion) is mounted directly on the motor shaft. The bearing of the output shaft is usually made of sintered materials. Attractively priced Output torque of up to 2 Nm Reduction ratio of 6:1 to 5752:1 Low noise level High efficiency maxon planetary gearhead Planetary gearheads are suitable for transferring high torque. The larger gearheads are normally equipped with ball bearings at the gearhead output. Torque up to 180 Nm Reduction ratio of 4:1 to 6285:1 High power in a small space maxon Koaxdrive The quiet maxon Koaxdrive gearhead combines worm and planetary gearheads. The signature characteristic of the drive is its unusually quiet running, even under heavy loads. Quiet High reduction ratio in the first stage Combined with maxon EC motors, ideal for medical technology. maxon spindle drive Spindle drives transfer the power generated by the motor into linear feed rate and feed force. The output shaft's bearings can absorb highest axial loads. Compact design due to direct integration of the spindle Comprises planetary gearhead with radial and axial bearings Designed for high forces and linear feed rates Wide range of spindles to suite any applicationWith integrated axial bearing for high axial loads: metric spindles, ball screws and trapezoidal screws are available.

Request for a quote

J-FLEX RUBBER PRODUCTS

United Kingdom

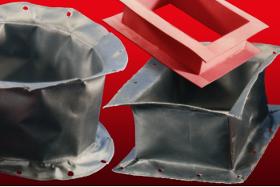

Custom Cut Gaskets, Inflatable Seals, Rubbber Bellows, Expansion Joints, O-rings, Vulcanised RIngs. Also, Fabricated Rubber Sleeves - including Mandrel Built Rubber Sleeves, Hand Fabricated Rubber Sleeves, Moulded Convoluted Sleeves and Bellows, High Frequency Welded Polyurethane and Stitched (sewn) Connectors.

Request for a quote

MATSDIRECT UK LIMITED

United Kingdom

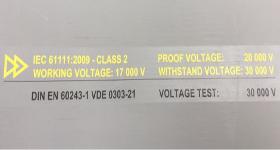

Today, we’re trusted by many blue chip companies in the oil, gas and shipping industries to supply them with high quality electrical safety matting. Over the years we’ve successfully exported electrical rubber switchboard matting to over 20 countries worldwide. All of our rubber insulating mats are then rigorously independently tested to comply with all the following specifications: European IEC61111, BS921, VDEO303 & American ASTM D178. As there is no time definition as to when the electrical safety matting should be replaced unless an electrical shock has occurred then it should be replaced immediately. The flutes are also a useful indicator of when the rubber matting should be replaced – just keep an eye out for any signs of wear over time. We also supply electrical safety matting with a smooth finish. Again, once this starts showing signs of wear just give us a call to arrange a replacement.

Request for a quoteResults for

Custom-cut - Import exportNumber of results

10 ProductsCompany type