- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air exhausters

Results for

Air exhausters - Import export

CIC - KLAUS CZERWONKA

Germany

Quick exhaust valves made of nickel-plated brass. For quick bleeding of cylinders and systems. On request also fully assembled with hose connections and exhaust air silencer. Available in sizes M5 – 1/2

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

NORELEM FRANCE

France

Industrial shock absorbers are maintenance-free, ready to install hydraulic components. They have an integrated fixed stop. The adjustable version enables precise adjustment to the desired dampening level. After installation, operate and adjust the shock absorber a few times until the desired braking level is achieved. Exceeding the max. energy intake per hour is possible if temporarily disconnected or the shock absorber is cooled with cylinder exhaust air. The installation position is arbitrary.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RUDOLF GUTBROD GMBH

Germany

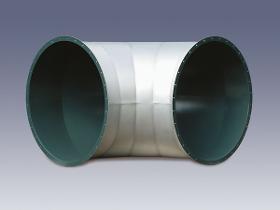

Special and flame retardant Just like ICS, ICS-ETFE is also suitable for coating stainless steel process and utility pipework, for example. As a special, flame-resistant interior coating, this is particularily suitable for the coating of exhaust air pipework, for example, in factories in the chip, solar cell and fibre optics industries. ICS is FM-approved - each construction part is marked separately with the FM specification. This coating is also tested according to the American safety standard Factory Mutual Research 4910 and suitable for use in clean rooms.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

with adjustable humidity and temperature to simulate the environmental conditions of a test specimen (e.g. household appliances, heating technology) The basis is a standard or climatic chamber (e.g. test kitchen, environmental simulation) with adjustable air humidity and temperature. On the basis of decades of experience in automotive test engineering, EP-E developed a concept in which the air flows in a circle (loop design). The result is a very excellent homogeneous temperature and humidity distribution. Through precise temperature and humidity control, it is possible to set different combinations of air conditioning and thus precisely adjust the required test conditions. The determination of the air flow (exhaust air volume) is carried out via a measuring section with the use of Laminar Flow Elements (LFEs). In order to determine the volume flow, pressure and temperature sensors are used to determine the air volume flow of the climatic chamber(s).

Request for a quote

TRIGGER

Germany

For the start of our book production, we have set great store, even with a run 1 the book block exactly in the envelope. For this we have acquired an English grooving machine, which can groove us the envelope before the book block is hung. The groove lines are set according to the page number and size of the book. They are then engraved in the envelope. The cover thus becomes something like a shaft with two hinges for the book block. This is then after the gluing of the spine. In the English brochure we put in the envelope before even 6 groove lines, so that the flaps later neatly turn over and the book cover does not bulge.We're not cooking hot glue any longer. Hot melt adhesives are increasingly suspected of producing carcinogenic vapors. They then gas during production and are extracted by suction and led into the environment via an exhaust air system. Our glue is neither carcinogenic nor has it to be boiled up. Nor does it emit any unpleasant odors, not during and not ...

Request for a quoteResults for

Air exhausters - Import exportNumber of results

10 ProductsCountries

Company type