- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air exchangers

Results for

Air exchangers - Import export

ANTHERMO GMBH

Germany

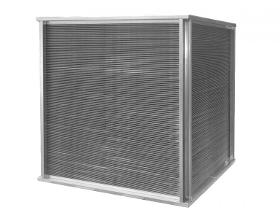

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

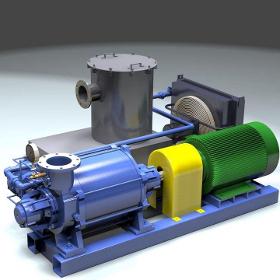

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteResults for

Air exchangers - Import exportNumber of results

9 ProductsCountries

Company type

Category