- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sequence controls

Results for

Sequence controls - Import export

TRANSMEC BELGIUM

Belgium

Multimodal distribution of supplies (land, rail, air, sea) Value-added services (sequencing, kitting, sub-assembly) Quality control of the suppliers involved in the customer’s supply chain, regardless of geographical location On-site services ranging from warehouse management and consolidation centres to just-in-time feeding of supply lines Product tracing Distribution of spare parts and finished products Implementation of dedicated IT systems Inbound/outbound logistics at our own facilities and on customers’ premises Management of customised and standardised industrial packages CKD logistics

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

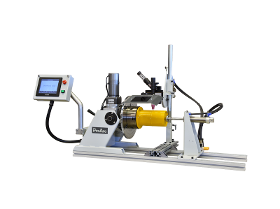

Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

GSW SCHWABE AG

Germany

Our sequence-controlled system includes a precision welding head and precise cutting and positioning devices. The two integrated Hydraulic Shears and the strip clamps can be moved so that the leading and trailing strip ends can be fitted precisely. For those who like it less automated but more cost-effective, we have developed a simpler technology – using just one Hydraulic Shear and fixed clamps. The strip ends are positioned manually here – this is supported by an easily accessible hand lever to individually activate the pneumatic clamps. A double edge guide with vertical rollers centers the new strip and can be adjusted also decentral for alignment. The actual welding process is taken over by the operator himself.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 660- for tube-Ø 6 - 60 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 420 - for tube-Ø from 4-20 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 645 - for tube-Ø 6 - 45 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

DYMAX EUROPE GMBH

Germany

HighIntensity lightcuring with patented intensity adjustment technology. Features: - >17,000 mW/cm² initial intensity - Patented intensity adjustment feature - Easy to use and adjust - Easytoread, lighted front panel LCD display - Improved user interface for easier operation - Up to 2,000 hours useful bulb life - Compatible with liquid, fiber, singlepole, or multipole lightguides - Integrate with pedal or PLC - Extended exposure time settings to 9,999.9 seconds - Controlled powerup sequence ensures proper temperature - Integral shutter with digital timer - Fast bulb replacement - Proprietary “Cool Blue™” filter virtually eliminates lightguide degradation - Smooth front panel for easy cleaning

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The SC 03 is an electropneumatic crimp press. It is equipped with a very efficient pedal switch. The correct and fully controlled sequence is monitored by a microprocessor control. The machine is started by a foot-switch. An integrated adjusting mechanism enables a correction of the crimping depth. Crimping tools can be changed easily and are available for the processing of ferrules with a size of up to 70 mm² with different crimping lengths. On customers demand special tools with different crimping geometries can be developed and manufactured.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Modular complete solution with cost advantage, for all single-flame-tube hot water and heating boilers — Intelligent sequence control for up to four boilers — Intuitive operation via colour touch display and function keys for quick access — Pre-configured and completely wired for quick commissioning — Integrated power supply in the compact control cabinet, e.g. for burner and pumps — Compatible with all common automation system protocols — Optional remote access via MEC Remote for maximum availability

Request for a quote

BESTACT SOLUTIONS INC.

Japan

Board-mounted bestact (R15) relay with built-in contacts, 2-contact output or 4-contact output can be selected, expanding the range of sequence control. Demonstrates reliability in a wide range of applications, from signal-level minute current circuits to inductive load switching power circuits. It has a wide range of current capacity and can be used to directly open and close inductive loads when used for PLC signal output. Compatible with flow soldering. Equipped with vibration and shock characteristics corresponding to railroad relays. It can be used in a wide range of temperatures and can handle battery voltage fluctuations in Rail car.

Request for a quote

BESTACT SOLUTIONS INC.

Japan

Board-mounted bestact (R25) relay with built-in contacts, 3-contact output contact configuration can be freely selected, expanding the range of sequence control. Demonstrates reliability in a wide range of applications, from signal-level minute current circuits to inductive load switching power circuits. It has a wide range of current capacity and can be used to directly open and close inductive loads when used for PLC signal output. Compatible with flow soldering. Equipped with vibration and shock characteristics corresponding to railroad relays. It can be used in a wide range of temperatures and can handle battery voltage fluctuations in Rail car.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ServoArc welding package can be simply applied in ProArc standard welding product by changing servo motor and integrate with advanced control box CB 500 or CB 600. 4 major advantages you will get 1. Equipped with servo motor 2. Welding program can be edited and stored 3. 0~10V analog interface available to control welding current 4. 3 additional dry contacts available for accessories such as Cold Wire Feeder, Arc Voltage control, Welding Oscillator etc.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

4 Major Advantage: 1. Cost effective and modular design.to increase welding productivity. 2. Set up with CB-107-1 Sequence controller : * User-friendly sequence controller. * Save 100 sets of programs * Even a non-experienced user can learn how to operate in few minutes. 3. High frequency protected 4. Suitable for different welding processes like TIG, MIG and plasma welding. 5. 2 year warranty *CE Conformity

Request for a quote

ELECTRO MAX

Romania

A Heliport beacon is a powerful light, omnidirectional intended to signal the presence of a heliport. The Heliport beacon flashes in Morse code the letter H. It is used especially when the helipads are surrounded by lights like in a city where it is hard to distinguish the heliports from the other lights. Description Light fixture body: powder-coated aluminum, RAL 1004 (aviation yellow) Diffuser: clear poly-carbonate Cable gland: nickel-plated brass Fasteners: stainless steel Light fixtures are provided with anti condensation valve Light fixtures are UV protected Electrical Characteristics The beacon must be powered and controlled by a special controller which creates the flashing sequence and alow the brightness control. The Heliport Beacon can be also controlled by the main heliport controller. Maximum pick power consumption is 120 W. The average consumption is less than 20W. Optical Characteristics The heliport beacon uses OSRAM White LEDs.

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Welding and cutting processes Depending on material and sheet thickness following processes are used: GMAW - Gas Metal Arc Welding (MIG/MAG) GTAW - Tungsten Inert Gas Welding (TIG), Cold & Hot Wire PAW - Plasma arc welding or cutting FSW - Friction Stir Welding Laser-Hybrid Welding RSW – Resistance Spot Welding igm robots may be used for all non-contact welding and cutting processes. Power sources from many well-known manufacturers can be integrated with our robot systems for welding and cutting applications. Products range from digital inverter power sources for MIG/MAG welding, TIG applications, plasma cutting and welding apparatus to high-capacity devices for the tandem process. Brushing, Grinding and Handling - Manipulation using Robots Through the possibilities afforded by a modular configuration of robot cells and the integration of diverse tools in the robot control sequence, significantly better throughput times and constant process qualities can be achieved. As a...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SERVOLIFT GMBH

Germany

Bin lifters from SERVOLIFT are adapted to your bin types. Its modular construction provides for functional extensions by combining special installed components and process machines. One can develop an optimal, ergonomic system solution when using the bin lifters in combination with Servolift containers. Universal handling of all bin types Technical description Stainless steel - or cGMP-compliant designs High flexibility, such as for containers of any dimension and design High load range Stationary or mobile design Floor/ceiling-installed, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Wide range of control designs, from simple, direct manual lever controls up to PLC-controlled sequences Integration of product controls, such as installation of dosing units Pick up of containers, including discharge aid and valve actuators Extensive take-up and clamp systems, container holding device, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • Potential-free contacts to upstream and downstream machines • High sealing tension due to a minimum distance from package to sealing unit • Programmable control with panel inclusive manual control with functional sequence of strapping control • Adjustable strap tension via touch panel • Low-wear, controlled strap path system • Stroke of strap guide frame via belt drive • Strap end detection with ejection of remaining strap • Wear-free DC drive, brushless motor technology • 10 freely configurable programs with up to 10 strapping positions

Request for a quote

TQ SYSTEMS GMBH - PRODUKTBEREICHE

Germany

SDB-40-100 Key functionalities: 100 kHz PWM rate Position-, speed- and torque control or mircro stepping mode Reference Specified values via fieldbus, parameter interface or analog control voltage Motor feedback via various encoder interfaces Acurate control of motion sequences with highest dynamics and precision Access to all relevant motor and control parameters Extended control and filtering capabilities in all control loops Extensive memory for real time logging Modulation of high electrical frequencies Availability: December 2015

Request for a quote

SMART MOTOR DEVICES OÜ

Estonia

SMSD‑4.2LAN is a new-generation stepper motor controller with advanced communication protocol. It is designed by our engineers for medium size stepper motors, output current is under 4.2A per motor's phase. The most useful advantage of the controller - remote control and Ethernet connection and control of a stepper motor using a local network. USB connection is also provided. Standalone motor control according to one of 4 independent executing program sequences, stored in the controller’s memory. Real time stepper motor control by commands via USB or through a local network Ethernet The controller provides 5 different control modes: real-time control by commands, motion control according to one of 4 executing programs, which are stored in a controller's memory; analog speed control; analog position control; STEP/DIR pulse position control. Digital I/O of the controller make it easy to use the controller together with other electronics of a system

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

NEXT GENERATION TECHNOLOGY The Batt-TDS™ inducts powders dust-free under vacuum into a stream of liquid, thereby creating conditions for optimal dispersion of diverse components in a continuous sequence. Independent control of key parameters, including flow and shear rates, offers a wide process window in a single piece of equipment. A ‘swiss-army knife’ of process tools for battery slurry Dispersion of diverse materials is tailored according to their specific physical properties and topologies with the capability to produce high-solids slurries at high viscosities. Scalable and cost-efficient The Batt-TDS achieves high product quality in a fraction of the time required by conventional processes. Easily scalable across various battery chemistries, the Batt-TDS solution is suitable for production at current industrial levels and ready for tomorrow’s gigafactories. The platform offers a low cost of ownership with the highest productivity per square meter of factory space.

Request for a quote

KONCAR - ELECTRONICS AND INFORMATICS LTD.

Croatia

System is equiped with: two channel digital voltage regulator, fully redundant thyristor power converters in 1+1 configuration, DC field circuit breakers and rotor overvoltage protection. It is suitable for large hydro and turbogenerators. The static excitation system is based on a robust modular design, engineered and designed to meet all modes of operation of large synchronous generators. The system is characterized by high accuracy, reliability and speed. The main characteristics of this system are: dual-channel redundant configuration, automatic voltage regulator, adjustable PID type, excitation current regulator, higher-level control functions (the reactive and active compensation by current generator, the Power Factor Controller / cos (φ) regulator, embedded power system stabilizer (PSS) ), integrated limiter functions, logic and sequence control, the possibility of extending the digital and analog inputs and outputs.

Request for a quote

SUSPA UK LTD.

United Kingdom

The gas strut, also called gas spring, gas pressure springs, gas dampers or gas pressure dampers, will solve your individual requirements for opening, closing, tilting and damping flaps, tables, seats or loungers thanks to our decades of experience. Gas struts take care of the controlled movement sequence and offer the following advantages: Simple installation Compact design Integrated damping Definable spring characteristic and extension speed

Request for a quote

RIDAT

United Kingdom

Ridat’s Roller Cutting Press (RCP) machines are designed to cut plastic thermoformed sheet, rubber, leather, board, foil and other gasket material, plastic foam, plastic coated or impregnated fabric. Production steps are as follows: Vacuum formed sheet is placed upside down on a cutting mould Board is placed on top and the sandwich is fed through the press A pair of pressure rollers causes the sandwich to press against the steel rule knife within the cutting mould thereby individualising the material. Key machine features include: Solid steel cutting pressure rollers Both pressure rollers are driven Electric motor gearbox drive Dual Control sequence switching - Jog or Run Steel Conveyor rollers CE Mark

Request for a quoteResults for

Sequence controls - Import exportNumber of results

27 ProductsCountries

Category

- Metallurgy - machinery and installations (4)

- Automation - systems and equipment (2)

- Relaying (2)

- Welding, electric - equipment and supplies (2)

- 3D scanner (1)

- Automatic piloting equipment (1)

- Biomedical equipment (1)

- Chemical industry - machinery and equipment (1)

- Cutting, plastics - machinery (1)

- Generating units (1)

- Lighting, street, industrial and commercial (1)

- Metal straightening machines (1)

- Packing and packaging - machinery and equipment (1)

- Pipes and tubes - ferrous metal (1)

- Plastic material processing (1)

- Road transport - logistical services (1)

- Springs (1)

- Steels and metals - welding and brazing (1)