- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- semi-automatic presses

Results for

Semi-automatic presses - Import export

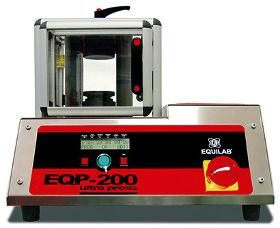

EQUILAB

Spain

The EQP-200 Pellet Press has been especially designed to obtain high quality pellets/tablets for XRF. This press can exert a pressure of up to 40 tons. Of durable and robust design, it is very easy to manage, efficient, and offers 5 working programs with single and double pressing cycles. An exceptional instrument. Keeping all the features of its predecessor (EQP-100), the EQP-200 also offers the possibility of making pellets of different diameters, just by changing the pressing tool. This device facilitates also the cleaning and maintenance tasks. Its versatility enables the unit to work also with different shapes of press tools, such as square, rectangular, etc.

Request for a quote

NEW SWAN

India

New Swan and Gunma Seiko (Japan) has entered into Technical Assistance Agreement for manufacturing of Cold Forged Parts of Aluminium and steel. Gunma Seiko is pioneer in manufacturing of Cold forged parts since decades. With joint aim of New Swan and Gunma Seiko (Japan)to cater Automotive sector, has entered into the ‘TAA’ to serve the automotive sector with Quality and Competitiveness. The plant is ready for production and machinery available for cold forging is Knuckle joint presses, Semi automatic bonding line, Annealing facility, Shot blast machines etc.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Semi-automatic filter presses represent a simplified and cost effective solution for the reliable operation with respect to operation and safety measures. This type of filter press is distinguished by a special, a rail-mounted two-hand control panel. The filter press with two-hand control is used in particular when the space on site is limited or a higher degree of automation is not required. Accordingly, a conventional version of the protective device is no longer effective. REDUCED PROCUREMENT COSTS AND SIMPLE OPERATION – THE SEMI-AUTOMATIC FILTER PRESS WITH TWO-HAND CONTROL FROM MSE Based on the safety technology requirements, an intelligent two-hand control is implemented, for example, for moving the filter plates by means of automated plate shifter. This functional principle thus prevents the operator from reaching into the working area. Complicated mechanical designs including further safety measures are not necessary.

Request for a quote

KOMAX HOLDING AG

Switzerland

This bench top crimping press is outstanding in terms of short cycle times, short changeover and setup times, programmable crimp height and the user-friendly TopTouch interface. These features, combined with the optional programmable stripper and bad part cutter, ensure top quality finished conductors regardless of the machine operator. Quality monitored crimping of single and multi-core cables is no problem with the semi-automatic bt 722 crimp press, not even when ultra-short stripping lengths are involved. Standard commercial crimping tools (left and back contact feed) can be used for processing.

Request for a quote

KOMAX HOLDING AG

Switzerland

The Komax bt 752 crimping press delivers three processes in a single device: stripping, seal loading and crimping. Reliability and top production performance coupled with the user friendly TopTouch interface are the features that make this semi-automatic device such a compelling product. Quality monitored crimping of single and multi-conductor cables is no problem with the semi-automatic bt 752 crimp press, not even when ultra-short stripping lengths are involved. Standard commercial crimping tools (left contact feed) can be used for processing. The controls are on a color touch screen and available in several different languages. System operation is fast, logical and symbol-based with the TopTouch user interface.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. GEM 350 / GEM 360 / GEM 820 WITH ADJUSTABLE FORMAT AND WITH UPPER AND LOWER DRIVE BELTS The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close boxes high and narrow. Ideal for fixed format boxes close (with constant height and width). Structure of the machine body made of sheet steel bent, bolted and painted. The movement of the cartons is done by two side drive belts driven by a single motor, adjustments for the different formats are made through flywheels. The machine is equipped with 4 wheels with brakes.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Thanks to the TNC-F model series, semi-automatic labelling of shaped bottles becomes very easy. The front and back labels should be on a carrier material. The product is inserted into a product pickup device. As soon as the 2-hand operation is activated, the system starts to pick up the product in the two format pucks, rotates and aligns the product before the front and back labels are applied exactly to the desired positions. By exchanging the format parts of the product pick-up device, cylindrical or angular products can also be processed and labelled with several labels in addition to the shaped bottles.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

HERMA GMBH

Germany

HERMA 211 HC - Feeding demand for personalized medical care The wrap-around labeler 211 HC reliably processes even the smallest batches and products that tend to tip over. Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes. Labels are applied by rotating these products horizontally between two motorized rollers and the pivot peel plate with application roller. The semi-automatic labeling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification. Optionally available with the innovative bad label return for the reliable removal of bad labels. The new 211 HC is therefore tailor-made for processing healthcare products.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 414 at a glance: Semi-automatic top labeling designed for a wide variety of formats on both flat and curved surfaces. For label dimensions of up to 100 mm in length and 160 mm in width. The heart of the system is the powerful HERMA 500. Entire machine is controlled by the HERMA 500’s basic drive unit. All necessary parameters can be conveniently set on the integrated operator display. Can be adjusted to different product diameters in no time at all. No control box or PLC required.

Request for a quote

OUTFISH

Latvia

Large semi-automatic tent for a family or friendly company. Two independent rooms with a spacious vestibule that allows you to store things or get together with the whole company. To accommodate a large number of people under one roof, we have developed a special convection-type flow ventilation that provides the interior with fresh air. Wind resistance: Medium. Fresh wind 9-11 m / s (30-40 km / h). A properly installed tent with fixed guy wires, stretched by pegs, with closed windows and an entrance is suitable for use with a wind force of 5, i.e. 40 km / h

Request for a quoteResults for

Semi-automatic presses - Import exportNumber of results

12 ProductsCompany type