- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- self-clinching nuts

Results for

Self-clinching nuts - Import export

HONSEL-GROUP

Germany

Self-clinch standoffs can serve as spacers or distance pieces. The hexagon head is simply pressed into the metal sheet, that the material will compress in the nut. The pressing in at the head finishes completely flush. A wide selection of open or closed versions is available. For applications with high strain versions with larger heads and higher compressive tensile strengths can be produced.

Request for a quote

HONSEL-GROUP

Germany

Self-clinch studs are fasteners that have a serration under the head. At inserting into the metal sheet it presses the displaced material into the rivet ring to secure the fastener. Sheet metal fasteners with internal and external threads are especially suitable for working with thin metal sheets starting with 0.5 mm thickness. This reduces the thickness of the elements in general in favour of lower weight and less material. Aft er processing they are permanently connected to the base material. The screwed connecti ons can be removed aft erwards without risking displacement of the fastener. Through this the production processes are rationalized and secured.

Request for a quote

HONSEL-GROUP

Germany

Self-clinching rivet nuts from series 10.455 and 10.456 are riveted into the component. A shaft is passed through a pre-punched hole in the component and riveted on the opposite side. The base material is not deformed in the process. These threaded fasteners feature serrated shafts that cut into the metal sheet surface, ensuring a high torsion resistance and torque load capacity. In addition to insertion with the aid of a press, these models can also be inserted using hand tools.

Request for a quote

HONSEL-GROUP

Germany

The self-clinch nut is a threaded fastener that has a knurl and a notch. The knurl ensures while embedding into the metal sheet the displaced material to spread evenly in the notch. This ensures an especially good stability. Advantages: • high resistance to torque strain • absolutely fl ush sheet metal backsides • compact and clean - ideal for example for use in electronic and light engineering

Request for a quote

HONSEL-GROUP

Germany

Self-clinch studs (flush head studs) are fasteners that have a serration under the head. At inserting into the metal sheet it presses the displaced material into the rivet ring to secure the fastener. Advantages: • high resistance to torque strain • no damage of coated surfaces - ideal for sheet panels • always vertical to the sheet • head is flush on the metal sheet after insertion

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The floating self-clinching nut has the special feature of allowing couplings even when there is a misalignment in the holes of the coupled objects. It is degned in two different versions: with a normal threaded hole and with a self-locking threaded hole. The nut can float up to 0.4 mm from the center, in all directions. The maximum total movement is 0.8 mm This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. The nut is fully installed when the sheet sits flush with the anvil face. So the result is aesthetically perfect and provides high tensile as well as torsional strength

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The flush self-clinching nut is a fully concealed element. Indispensable when you want to have the sheet metal completely smooth, free of protrusions on both sides This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch, applyinng only sufficient pressure to squeeze the nut into the parent sheet. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. After installation the hexagon head should be flush with the sheet and the spigot should not protrude through the opposite side. So the result is aesthetically perfect and hexagon head provides high tensile as well as torsional strength The nut can be mounted on already painted or treated sheet metal as it requires no further processing after installation

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

This self-clinching broaching nut for plastic materials is widely used in the electronics industry. It offers a threaded hole of high resistance to both torsion and tensile strength This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The parent material experiences plastic deformation and locks the fastener firmly to itself Standard material: Electro tin plated steel and stainless steel

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

M3 - M 24 Materials: Class 4.8,Class 8,SS304,SS316 Standard:DIN 980

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Hexagon Flange Self-lock Nuts M5-M16 Materials: Class 4.8 (normal), Class 8.8 (customized) Finished: Zinc plated Origin: China

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

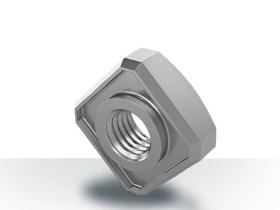

With PIAS® pierce-clinch nuts (square) and RIVTEX® (ROUND) a non-detachable metal fastening can be created at optimum cost. The pierce-clinching technology is suitable for steel and aluminium sheets, causes very little cost for inspection and control, and allows several pierce-clinch screws to be processed in a single stroke. PIAS® and RIVTEX® pierce-clinch nuts offer the following advantages over welded nuts: corrosion-resistant no weld spatter on the thread no thermal weakening at the fastening position self-piercing higher torque requirements high process reliability in fully-automated processing flush-mounted processing processing can be manual, semi or fully automated self-locking thread possible

Request for a quoteResults for

Self-clinching nuts - Import exportNumber of results

12 ProductsCountries

Company type