- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- self lubricating bearings

Results for

Self lubricating bearings - Import export

IGUS® GMBH

Germany

iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]: iglidur® clip bearings are especially intended for the shaft bushing through plates. For this reason the bearing has a flange on each of the two front sides. After the clip-on the bearings are secured on both sides in the plate. The clip bearings have chamfered slot on the side that enables the mounting of the bearing on one side. After the mounting the bearing straddles and lines the bore in the plate. The shaft prevents the clip bearing from slipping out of the bore. The bearing cannot slip out of the bore even in axial movements. Extremely simple mounting through lateral slot Maintenance-free and self-lubricating Good flexibility in punch hole Good abrasion resistance Quiet operation Suitable for rotary and linear movements Extendibility through the slot Undetachable through double flange Special dimensions possible Plate thicknesses from 3 mm to 4 mm available from stock Material: iglidur® M250 Special properties of the iglidur® clip bearings iglidur® clip bearings are made from the most abrasion-resistant material, iglidur® M250. iglidur® M250 is a bearing material for rugged, wear-resistant bearing systems for medium loads. The bearings are self-lubricating and can be used dry. If required the bearings can also be lubricated. The material iglidur® M250 is resistant to all common lubricants. The iglidur® clip bearings are the ideal solution for bearing functions with low loads. The easy mounting makes it ideal for applications with difficult bearing locations. Compressive strength The permitted static surface pressure of iglidur® M250 amounts to 20 MPa at room temperature. Due to the good adaptability to uneven surfaces of the bearing housing, a high pressure load capacity of the clip bearings persists even in punched holes. For the most small bearing surfaces, the good vibration dampening properties and the insensitivity to misalignment are of primary importance. Surface speeds Clip bearings are particularly wear resistant in slow rotating, oscillating and axial motions. You can find the maximum gliding speeds for the various motions for the iglidur® M250 material under the materials data link shown below. A lubrication at installation or continuous lubrication raises the permitted surface speeds. Clip bearings are available from stock in dimensions of 3 to 25 mm. Fixation Triflex RS For mounting, the bearings are laterally pressed together with the large flange. The chamfered slot makes the bearing spiral-shaped, whereby it can be easily inserted in the plate. The remaining slot in the attached clip bearing can compensate for linear expansions of the circumference. Thus narrow bearing clearances are possible with clip bearings. The bearing clearance is dimensioned in such a way that in a housing bore with a nominal diameter, a shaft made with the same nominal diameter turns easily. The clip bearing can be used in H-tolerance housings up to H13. The turning of the clip bearing in the bore is also permitted. Operating temperatures The wear resistance of the iglidur® clip bearings are excellent with operating temperatures till 80°C. Even at low temperature the bearings remain elastic and abrasion resistant. When to use it? When a sheet metal feedthrough is required When the bearing should be captively clipped on in a drill hole with rough tolerance For rotating, linear and pivoting movements When a quick-mounting bearing solution is sought Clip bearings application examples When not to use it? When constant temperatures of more than +80°C occur iglidur® G When a high-precision bearing is needed iglidur® J When the housing bore is more than 4 mm long iglidur® Clips 2 iglidur® MKM When very high surface pressures occur iglidur® G iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]:

Request for a quote

GLT BEARINGS GMBH

Germany

Filament-wound composite bearing with self-lubricating inner | Surface backed with a high-strength | Maintenance-free | With a sliding layer of PTFE with lubricant additives COM-KU®/M is a self-lubricating and maintenance-free plastic plain bearing. Using a heavy-duty glass fibre fabric combined with a selected binder resin helps to increase the mechanical properties, pressure further and wear resistance of this bearing type. The special lubricant additives and the PTFE in the sliding layer reduce the friction coefficient, optimising the wear behaviour and thus the material's service life as a dry sliding bearing. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

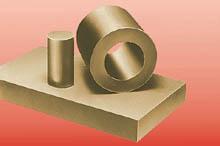

Sintered bronze plain bearings | Maintenance-free | Oil-impregnated | Self-lubricating | DIN 1850 / ISO 2795 SIB-MET® is a self-lubricating and maintenance-free plain bearing. Suitable for high speeds at low loads. Suitable for high sliding speed at low load capacity. For technical details, please visit the product page on our website!

Request for a quote

LUTZ PUMPEN GMBH

Germany

When circulating chemicals and pickling baths, reliability, safety and last but not least functionality are important. The submersible centrifugal pump was specially developed as a vertical, wet-installed pump for the rapid emptying of these liquids from tanks and basins. * available in special immersion depths on request * equipped with self-lubricating, liquid-wetted plain bearings. Features & Advantages * High flow rate * High efficiency * Smooth running * Low space requirement * Easy commissioning * Easy to maintain * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

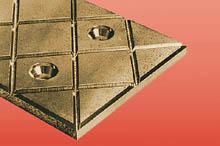

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

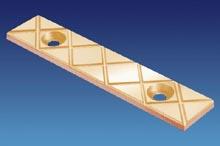

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

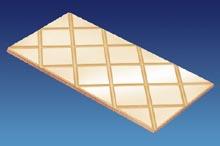

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

As a tapped hole is prepared for the centralized piping on the stud head, this is optimal for applications where centralized oil piping is necessary.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Top-class low-friction engine oil in Aral synthesis technology for current commercial vehicle diesel engines with the suitability for long oil change intervals. Meets the high requirements of commercial vehicle manufacturers as well as the strict European test requirements. Application Suitable for applications in Euro 6, Euro 5, Euro 4, Euro 3 and Euro 2 engines in commercial vehicles, construction and agricultural machinery that do not require "Low SAPS engine oil" and that require the specifications mentioned. Please observe the manufacturer's instructions in the maintenance manual. Specifications ACEA E4, E7 API CI-4 JASO DH-1 MB approval 228.5 MAN M 3277 Volvo VDS-3 RVI RLD-2 Cummins CES 20077, CES 20078 MTU oil category 3 Mack EO-N DDC Power Guard 93K215 Deutz DQC III-10

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Mineral oil-based transmission fluid for applications in which performance class API GL-4 is required. Approved for ZF manual transmissions. Advantages high thermal stability to protect against deposits and oil thickening ensures the operational safety and long service life of the lubricant and unit excellent wear protection and load-carrying capacity for long service lives Specifications API GL-4 MAN 341 Type Z2 ZF TE-ML 02B, 17A

Request for a quoteResults for

Self lubricating bearings - Import exportNumber of results

29 ProductsCountries