- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- selective soldering

Results for

Selective soldering - Import export

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

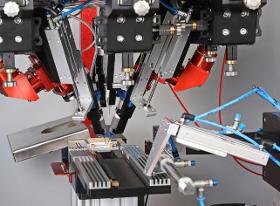

SELECTIO Selective soldering systems for automatic single point soldering and multiple point soldering It is not always possible to use mass soldering processes such as wave soldering to perform a certain soldering task. Individual soldering steps are often necessary. To automate this process and to lower the costs while maintaining the high quality requirements, STRECKFUSS SYSTEMS has developed the selective soldering system SELECTIO. Just like our wave soldering system TITANIUM, SELECTIO too is equipped with the corrosion and tin resistant agent titanium and therefore works perfectly for lead free soldering. Product characteristics – an overview: x/y/z- axes system with precision toothed drive belt transport system and assembly carrier standard stand- alone- system (offline system): optional transportation belt connection as inline system printed circuit board transportation with assembly carrier soldering processes: single point nozzle and surface nozzle as well as dip soldering via mask technique fluxing out of vendor's flux container with multi- drop- fluxer nozzle short wave IR- quartz- radiators for preheating of printed circuit boards pyrometer for contact- free temperature check of printed circuit boards easily exchangeable soldering nozzles Microsoft© Windows user surface and process visualization: - BDE for documentation complying with DIN ISO 9000 ff - management data organization - optional real- time video surveillance

Request for a quote

MTA ROBOTICS AG

Switzerland

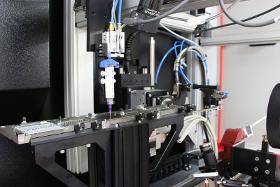

As a complement or an alternative to wave, mini-wave and traditional selective soldering techniques, the MPS700 bottom side selective soldering machine provides maximum accessibility and meets mass production requirements of quality, reliability and cycle times. The iron head is equipped with a powerful heating element and a high precision wire feeder. The solder point positions are adjusted using a compact vision system close to the iron head. A 4-axis system guarantees quick and precise movements. The MPS700 can be equipped with mta classic soldering iron head and MSH150 soldering iron head.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

MTA ROBOTICS AG

Switzerland

The mta OEM soldering robot for integrator can be used for semi or fully automatic operations of selective point to point soldering from above. Thanks to its unique concept, the OEM robot is delivered to the system’s manufacturer with a process guarantee. The OEM robot can be equipped with any of mta’s soldering heads: soldering iron, induction, microflame; except for the mta MLH45 laser head. The 3 or 4 axes of the OEM robot are fully programmable through the mta-MotionEditor software, including soldering parameters such as: Solder quantity, wire feed speed, preheating/postheating times, automatic tip cleaning cycle intervals and other parameters for each soldered point. With its flexible and modular concept, the OEM robot can be fully and easily integrated into a production line.

Request for a quote

BERATRONIC GMBH

Germany

Our services •Layout creation •Material procurement •SMD assembly •Manual and semi-automatic •Mounting •Reflow and wave soldering •Selective soldering •Automatic Optical Inspection (AOI) •X-ray inspection •System assemblies •In circuit tests and •Function test •Revision and repair •Rework Station •Short delivery times

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

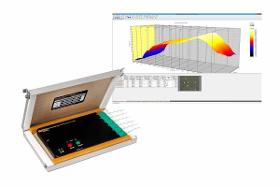

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Reflow Tracker temperature profiling systems Program includes — range of high-accuracy, industrial-strength, compact Datapaq DP5 data loggers — range of low-height thermal barriers — DATAPAQ Insight Reflow Tracker analysis software — selection of fast-response, high-temperature thermocouples for measuring SMD and PCB temperatures and process stability Applications include — WAVE SOLDERING – accessory: DATAPAQ wave pallet with up to 9 contact sensors and 3 preheat sensors; software functions include contact times and parallelism — SELECTIVE SOLDERING – accessory: DATAPAQ PA2200 selective soldering sensor for process stability measurement — VACUUM SOLDERING – optional data transmission via radio enables real-time data analysis — VAPOR PHASE SOLDERING – program includes a special range of sealed and lighter-weight thermal barriers — REWORK STATIONS – the DATAPAQ DP5 data logger with its USB and Bluetooth connectivity is ideal for high-speed, real-time monitoring

Request for a quote

NANOSYSTEC GMBH

Germany

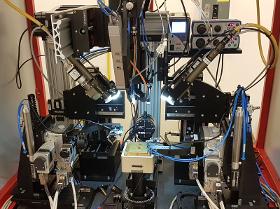

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

NANOSYSTEC GMBH

Germany

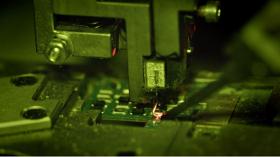

NanoSolder actively aligns optical components such as photonic circuits, waveguides, diode lasers and photodiodes. It uses selective laser soldering for the assembly. Compared to gluing with subsequent curing, much shorter assembly times will be achieved by selective laser soldering.

Request for a quote

NANOSYSTEC GMBH

Germany

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

NANOSYSTEC GMBH

Germany

VersaSolder uses selective laser soldering for applications where other methods fail. A laser beam heats an area without impacting the surrounding the key advantage of this non-contact joining technique.A lens assembly focuses the laser power which melts the solder onto the working area. It is tailored exactly to the specific shape of the solder joint and the beam may be circular, elliptic or a straight line. An optional pyrometer measures the temperature in the melt pot and the electronic actively regulates the power profile. Multiple solder heads heat various areas at the same time and a symmetrical arrangement reduces shift. In order to achieve higher productivity, nanosystec developed the Multi Beam Optic (MBO). It generates a number of sub beams processing more than one connection in the same time – up to 40 individual spots have been demonstrated.

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

From component preparation to precise soldering and checking: our THT assembly Our skilled employees take care of the manual component preparation on site so that the component later fits perfectly on the circuit board. We also have our own parts warehouse, with which we ensure reliable production of your THT orders. The THT assembly area at A + B Electronic includes three selective soldering systems and two wave soldering systems. Depending on the equipment, the right soldering process is selected. With the Ersa VERSAFLOW 4/55 selective soldering machine, we also have a system of the latest product generation. What speaks for us: -Contact person for prototypes, large or small series -A high mix of components is not a problem -We test the technical feasibility of your project before each order -We are not just a service provider, but a technology partner: A+B Electronic thinks through your project with you and together we can bring it to successful series production

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Whether with a mini-wave or a Wörthmann wave, we deliver customary RAFI Eltec quality on our automatic soldering equipment even for wired assemblies. We apply various technologies here – coordinated to each individual project. Our focuses: - Wired assembly - Wave soldering (ROHS-compliant or leaded) - Automated selective soldering - Lift-dip soldering (multi-wave) - Manual soldering - Assembly - Visual inspection You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quoteResults for

Selective soldering - Import exportNumber of results

14 ProductsCountries