- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seamless monitoring

Results for

Seamless monitoring - Import export

FESSMANN GMBH UND CO KG

Germany

Creating highquality products in the food industry means balancing the desire for flexibility in the production of goods with absolute process reliability. This requires constant, seamless monitoring of all processes, as well as careful documentation of every intervention in the program flow. The FOOD.CON 2 adapts to your requirements. Equipped with a 12" touch screen made of special protective glass, the control is intuitive to operate and the selfdiagnosis function through fieldbus communication with all important components of the system ensures minimum downtimes and maximum system availability. Program optimizations can be carried out via remote maintenance via external access or directly via smartphone. During operation, the FOOD.CON 2 enables the precise monitoring of all important parameters in the system chamber temperature, humidity, core temperatures and much more are permanently recorded and made available as graphic evaluation for quality control.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

ERTEMES GMBH

Germany

The Hawk user interface gives you full control over your measurement. The interface of the Hawk GUI offers the possibility of a simple and clear configuration of all measurement channels, as well as the control of data acquisition during the actual measurement. It also provides an overview of the organization of all measurement PCs and amplifiers in the network. •,Interface for configuring all connected measuring devices. •,Configuration of various limit values to monitor the measurement. •,Seamless recording of your measurement •,Define individual time ranges (manoeuvres) to make them easier to identify in the downstream analysis. •,Configuration of additional, external amplifier hardware can be integrated. •,No license fees for using the software. •,MS Windows compatible

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

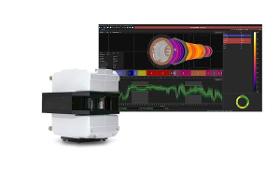

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Seamless monitoring - Import exportNumber of results

6 ProductsCountries

Company type