- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screw feeders

Results for

Screw feeders - Import export

NOVELTY STEEL

Turkey

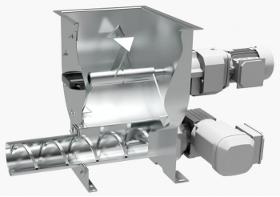

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at low feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-489 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7500 dm³/h

Request for a quote

MIX SRL

Italy

Dynamic components for the construction of screw feeders suitable for conveying powder, grain and fibre products

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

ROBINSON CO.

Turkey

The cylindrical body structure is produced in a structure suitable for the product flow in one or both sides, depending on the project conditions, with supporting legs suitable for connecting to the floor deck or floor. The vibro feeding system connected to the conical structure has an adjustable flow flap and is driven by a vibromotor. In flour factories, it is used in the parts that require the adjustment of the ground grains at the appropriate flow and simple feeding, generally in the parts where the filter outlets need to feed a pneumatic line or a machine and where the dust wastes are brought into the system with pneumatics.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Brand Name jiayi Condition New Weight (KG) 4Video outgoing-inspection Provided Machinery Test Report Provided Marketing Type New Product 2020 Warranty of core components 1 Year Core Components Bearing, Motor Warranty 1 Year Applicable Industries Manufacturing Plant Showroom Location None Dimensions 232mmX162mmX169mm

Request for a quote

THOMSON MACHINERY BV

Netherlands

Dimensions L350*W400*H220(mm) Voltage AC 220V50HZ Air pressure 2-3fkg/cm² Working temperature 5-40ºC Working humidity 20%-90%RH Feeder capacity 2000-5000pcs Efficiency 50-70pcs/min Feeder mode Vibratory feeder Screw Delivery Method Blowing type Applicable screw M2-M6 Working Efficiency 0.8s/screw Weight 15kg

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The auger feeder series enables the volumetric dosing of powdery products with fine granulation, which can sometimes present problems of compactness, dust content and variable density, such as cocoa, curry and other "powdery" products. The various problems associated with processing the products are solved, starting with feeding the product through a hermetically sealed hopper equipped with a level sensor and a motorised agitator. The screw, made from a single solid mass, has an electronically controlled speed by means of a servo motor, which allows the use of acceleration and deceleration ramps that ensure an immediate screw stop, thus guaranteeing optimum dosing accuracy.

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quote

ENVEA

France

Microwave sensor for continuous moisture measurement in dry bulk solids and installation on conveyor belts, screw feeder or hoppers. Microwave based sensor for high resolution and accuracy. • highly resistant to abrasion • integrated temperature reading • flow detection function • moisture ranges 0 65 % • measurement accuracy 0.1 % • ATEXcertified

Request for a quote

ENVEA

France

Sensor for continuous moisture measurement in dry bulk solids and installation on conveyor belts, screw feeder or hoppers. Microwave based sensor for high resolution and accuracy. • highly resistant to abrasion • extended measurement range, up to 85 % moisture • high temperature version up to 190 °C • measurement accuracy 0.1 % • recording of surface moisture and capillary moisture

Request for a quote

STATEC BINDER GMBH

Austria

Currently there are three net weighers in our product portfolio. The differences are in the product feeding. Our weighers are equipped with gravity, belt or screw feeders depending on which product has to be weighed. The choice of product feeding depends primarily on how well the product is free flowing. Moderately flowing as well as powdery and fine products are rather weighed with belt or screw feeding, while free-flowing bulk goods are usually weighed with gravity feeding. The high quality standard of STATEC BINDER is also achieved here through the use of stainless steel and a sturdy and compact design. The use of stainless steel guarantees longevity and high operational reliability even under demanding conditions.

Request for a quote

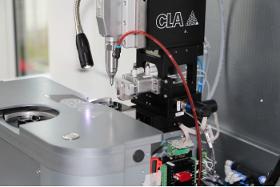

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automatic screwdriver with torque measurement Compact station for workbench to ensure your assemblies screwed with high precision torque control. Main features : - Screws feeder by vibrating bowl - Preparation of the next screw in hidden time - Automatic screwdriver with integrated torque sensor - Preparation of the next part in hidden time thanks to the charging carousel - Removable precision tool to ensures a precise positioning and a multi-types parts management - User friendly interface allowing various screwing positions and configurations dedicated by type of parts - Ready to be integrate in assembly line

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRESSTA EISELE GMBH

Germany

Fully automatic operation Motor 7,5 KW, S6, 400V / 50 Hz, 2850 R.P.M. For the use of saw blade Ø 550 mm Big cutting range Max cutting height up to 150 mm Max cutting width up to 270 mm 90° cuts Remaining piece from 75 mm Table separation before sawblade retracts powered ball screw spindle material feeder up to 600mm Feed length up to 600mm, Multiple movement of the feeder possible up to 9,9 m

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation cutting of aluminium and non-ferrous metal NC Control with touch screen display 5,7” Piece counter showing target/actual number of pieces Piece multiplier when cutting bundles Indication of cycle time Multiple feed device – max feed 3.250mm Table separation before the saw blade retracts so the profile is not touched by the saw blade Electronic material feeder, ball screw spindle and servo motor incl. pneumatic horizontal and vertical clamps Float mounting feeder to balance bend profiles Waste piece from 85mm Reducer of clamping pressure horizontal and vertical Cycle spray mist device with level indicator and automatic stop Cut-off length from 3mm Automatic cut-out when bar is finished Technical Data: Motor up to 18,5kW, S 6 40%, 400 V, 50 Hz, 2850 R.P.M. r.p.m. infinitely adjustable Saw blade speed 3.500 – 5.800 R.P.M Saw blade Ø 400mm Profile width max 200mm height max 120mm

Request for a quote

PRESSTA EISELE GMBH

Germany

High-Performance automatic circular saw for aluminium and non-ferrous heavy metal Fully automatic operation Use of TCT or solid carbide blades ø 250 mm Motor 7,5KW, 400 V, 50 Hz, infinitely adjustable Blade feeder hydropneumatic Material feeder with ball screw spindle and servo motor 2-axis NC control Simatic S7-300 with 7“ touch screen Cutting range: height up to 60 mm, width up to 140 mm Manual safety cover 2x Ø 100 mm swarf extraction connector Blade feeder pneumatic hydraulic controled vertical top to down Manual blade feed adjustment to optimize the feed length Pneumatic clamps horizontal left and right of the blade Diagnosis of errors, trouble shooting Pneumatic clamps vertical left of the blade Mist spray blade lubrication (filling level controlled) 1 l tank Parts slide (Option: conveying belt) Material feeder from 2 – 650 mm with ball screw spindle and servo motor Multiple material feed possible up to 3250 mm cutting length Vertical and horizontal clamps Reducer of...

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Quard® is a martensitic abrasion resistant steel with average hardnesses between 400HBW and 550HBW. it is produced at NLMK Clabecq, where they are treated in a state-of-the-art Quenching and Tempering unit. The steel plates are specific for applications used in hard environments and subject to wear. Quard is recommended for mining and earthmoving equipments and for machines in the recycling or cement industry. The use of Quard® may result in product lifetime being more than tripled when compared to products made from standard grades of steel. Applications: Buckets, knives, grapples, dumper bodies and on road tippers, refuse haulers, scrap containers and scrap presses, feeders, skips, screw conveyors, screeners, crushing and pulverizing equipment, etc. Thickness : Quard 4004-50 mm Quard 4503.2-64 mm Quard 5004-40 mm Quard 5506-30 mm Width : 1500-3100 mm Quard is a martensitic abrasion resistant steel.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-2693 dm³/h 20 - 2693 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — except model DSR28 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7088 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — 3 phase AC gear motors — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-298 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Loss-in-weight feeder for powders and pellets — Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-3743 dm³/h 20-3743 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 20-7610 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates — Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20) Power range - Different versions 1-25570 dm³/h

Request for a quote

IMETA SRL

Italy

This feeder was initially designed for installation on the Angelus 60 L and was then adapted for many other machines. The innovative feature here is that the feeding screw is inclined and parallel to the cover stack, making the feeding more natural and fluid. This feeder is adjustable and, with the substitution of just a few parts, it is suitable for any cover diameter (between 50 and 105mm).

Request for a quote

COMERC SP. Z O.O.

Poland

Screw conveyorsare used for transporting sawdust, wood chips, pellets and other bulk materials. Conveyor housing is made of structural steel with Magnelis® coating. Wormwheel is made of thick-walled steel pipe with 10 mm thick spiral welded to the pipe. End necks welded on both ends of the wormwheel are designed to be mounted in high-quality self-aligning ball bearings (SKF or INA/FAG) with UCF housing. Additionally, our screw conveyors are equipped with rotation monitoring sensors and inspection hatches with overflow sensors.Depending on the requirements and purpose belt conveyors could work with capacities from 15 m3/h to 100 m3/h. Screw conveyors (also known as auger feeders) are used in various industries, and their design can be adapted to the specifics of each industry, if necessary. The screw feeders we manufacture are part of the pellet production lineswe design and build, and ensure stable, even feeding of the raw material to the next production stage.

Request for a quoteResults for

Screw feeders - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Weighing and dosing equipment (10)

- Biomass energy - production (2)

- Dosing - machines and equipment (2)

- Measurement and regulation equipment and instruments - output and flow (2)

- Mining and quarrying - machinery and equipment (2)

- Packing and packaging - machinery and equipment (2)

- Paper - Printing - Machines & Equipment (2)

- Assembly robots (1)

- Automation - systems and equipment (1)

- Coupling, pneumatic (1)

- Extraction machinery and equipment - minerals and ores (1)

- Flour-milling (1)

- Machine tools, metal machining - parts and accessories (1)

- Pneumatic conveyor equipment (1)

- Robotics (1)

- Tar and asphalt - construction materials (1)

- Troughs and feeders (1)