- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screening drum

Results for

Screening drum - Import export

ADVANCED ENGINEERING WEDGE WIRE

Turkey

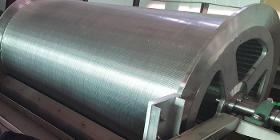

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

There are many techniques to separate waste. Bezner has developed screening machines for the recycling industry with linear, circular, rotating, and elliptical (ballistic) sieving motions. We offer in-house engineering and manufacturing of screening machinery.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

A screening drum, or also referred to as trommel screen or rotary drum screen, is a machine for classifying, size splitting, and pre-sorting waste in a waste management plant, recycling plant or compost plant.

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

We supply internally and externally fed drum screens for manifold kinds of application. Contact us – our machines could be the solution for your application problem! Internally fed drum screen Externally fed drum screen

Do you sell or make similar products?

Sign up to europages and have your products listed

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application Increasing fees for sewage water make high demands on in-plant sewage treatment plants. The internally fed sieve drum CenterFlow is a product to face manifold problems, designed for liquid/solid separation in the field of process and waste water of industries or WWTPs. Function The rugged sieve drum is the core of the CenterFlow. Here, the particles are retained and carefully dewatered for further discharge. Within the inlet chamber the flowing-in medium is homogenized and the flow velocity reduced. The tangentially approached sieve surface serves to efficient fine sieving even of high hydraulic loads. Due to the drum configuration the main task can either be a fast solids discharge or a slower passage through the drum if the retained solids are to be, in addition, washed or properly dewatered. With a constant rotational speed and a low drive power this sieve drum machine is a reliable component within the equipment of a plant. The high availability and the large...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Brief Description The PWL compact unit MODULAR is a multifunction unit combining waste water sieving with the discharge of grit and grease in one compact system. Due to its modular design the PWL compact unit can be equipped appropriate to individual waste water conditions. Among all kinds of screens the MODULAR can be used with drum screens within the inlet area. The different kinds of solids are separately carried out of the unit for further treatment or discharged into a container. Function Via pumps or gravity flow the waste water reaches the headbox of the MODULAR. The screen integrated into the headbox discharges the separable solids from there either to the downstream PWL Interval-Wash-Compactor or into a container. The waste water charged with organic and sand runs off directly from the headbox into the aerated grit chamber. The free fats and lightweight substances reach due to the prevailing roller stream the integrated grease trap. The arising floating layer is...

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

In the cryogenic blasting process, an enrichment of rubber and plastic waste powder takes place due to fine abrasion during the treatment procedure. Thus the performance and processing time of the blasting-media will deteriorate and decrease its jet-energy. In our cryognic deflashing machines, the blasting-media is primary screened by the treatment drum perforation, however, after a long operating time the amount of rubber and plastic waste powder increases. In order to guarantee a constant, statistically secure and economic processing, this powder has to be removed periodically from the blasting-media. Our automatically working blasting-media recovery machine consists of a suction & drying system and a vibrating-screen unit. The used blasting-media has to be aspirated manually from the deflashing machine. The drying of the polluted wet and cold media takes place in the suction tank and the cleaning by screening with final separation into waste powder, waste media & re-usable media,

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Extraction, crushing and grinding plants and their consumables: mills, hoppers, gutters, screens, trellises, conveyor belts, drums, rollers, fences, geared motors, buildings, supports, crushers, passageways, ladders, guardrails…

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS: Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: Front Dome: 4 mm Rear Dome: 4 mm Drum Capacity: 1000 liters Meat Carrying Capacity: 350 kg Vacuum System Hydraulic System Maximum Safety Automatic Ready Recipe Easy Operation with Digital Touch Screen Drum Bearing Rollers: FAG or SKF brand bearings are used. ETDYSH - 1000 Mixer Gearbox: 2.2 KW The reducers used are YILMAZ brand, KR series. ETDYSH - 1000 Meat Mixing Tulmbler: Equipped with one 0.70 KW vacuum pump. Electrical Components: Utilizing SCHNIDER or DELTA electrical components.

Request for a quote

TEKNIK MAKINA

Turkey

Gold Trommel Scrubber Gold Drum Screen Gold Rotary Screen Measurement : 1000*1500 mm 1000*3000 mm 1200*3000 mm 1500*4500 mm 1800*6000 mm 2000*6000 mm

Request for a quote

OFFICINE CONTERNO SRL

Italy

The professionalism of Officine Conterno does not end with the design and construction of machines and plants for aggregate and waste processing, but also extends to after-sales. For all machinery maintenance and repair needs, Conterno provides an efficient technical assistance service, which is able to provide for the rapid and complete recovery of your plant at both structural and functional level. We are also able to provide replacement parts for all types of aggregate processing machines, all of which are certified and guaranteed. The following is a list of the main spare parts supplied by the company, including for machines of the leading Italian and foreign manufacturers: • Jaws • Armour for mills and crushers • Hammers for mills and crushers • Steel meshes • Polyurethane meshes • Rubber meshes • Bearings for screens • Rubber mats • Scrapers • Rollers • Drums • Gearboxes for belts ... and many other mechanical parts for all types of machine.

Request for a quote

GULMAK GIDA TURIZM MAKINA LTD. STI

Turkey

Sugar coating machine available in two models: DSK03 - M (5-10 kg/ per hour) and DSK03 (80 kg/ per hour). Button control. (additional PLC screen); the coating drum is made of copper material. For all information please contact us.

Request for a quoteResults for

Screening drum - Import exportNumber of results

14 ProductsCountries

Company type

Category

- Filtering equipment and supplies (1)

- Meat processing machines (1)

- Mining and quarrying - machinery and equipment (1)

- Moulding, rubber - machinery (1)

- Recycling - machines and installations (1)

- Sugar refineries - machinery and equipment (1)

- Turning - steels and metals (1)

- Waste sorting - machines and equipment (1)

- Water treatment, industrial - systems and equipment (1)