- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screen mesh

Results for

Screen mesh - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating Circular motion screens divide into several bulk grain size ranges, seven small amounts of over-or undersize or separate from impurities and foreign matter from the screenings. Vibrating screens are working with directed vibrations/amplitudes, which are selected on special product to screen, depending on the installation conditions. The screens can separate different fractions simultaneously. The choice of the screen size and dimension depend on the task. Advantages & benefits low operating costs, high operational safety, long service life good value for money compact design dust-proof design possible low wear different possible screening performance, depending on size and design different possible meshes and screen shapes possible different possible screen materials (PU, spring steel, stainless steel, wedge-wire screens, perforated plates, etc.) Construction The main components are: strainer with drive traverse strainers / cassette or tensioned version mechanism

Request for a quote

INSCREEN SA

Greece

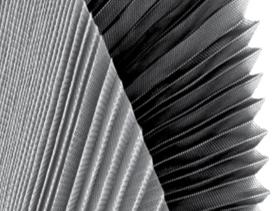

Polyester Pleated Mesh: Accordion style mesh made of reinforced polyester combustible material, used exclusively in pleated systems and offering significant elasticity and great visibility. In its standard version, the mesh is available in black color and in grey color only upon request.Width of the pleat: 15 mm και 20 mm. Fiberglass Stiff Mesh: High durability mesh, ideal for large-sized screens. In its standard version, the mesh is available in grey color and in black color only upon request. Mesh Dimensions (length x height available in roll): 160x90, 240x90 Applied to: KLIP Vertical & Horizontal, FRONTAL, Indoor, Inframe and sliding typologies. Fiberglass Soft Mesh: Mesh that offers good elasticity and has been established as the ideal solution for hinged and fixed frames applications. In its standard version, the mesh is available in grey color and in black color only upon request.Mesh Dimensions (length x height available in roll): 60x30

Request for a quote

SIGA FILTRATION

United Kingdom

SF-IL Inline Screen Filters Heavy duty industrial inline screen filters for coarse applications. Standard units are supplied with inline connections for easy istallation. Industrial design Range of screen sizes Hinged closure Stainless Steel Construction PN16 flange 10 bar pressure rating PED compliant F-SF Inline Bulk Transfer Filter Designed for product transfers from holding tanks to tankers. Ideal for product transfers from tankers to tanks Industrial or hygienic design Camlock couplings for quick connections Clamp closure for easy maintenance Basket in range of mesh sizes PED 10 bar -10 / 80 °C

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Grade Cleaner is mainly used to sizing the different sizes of seeds, kernels, nuts, beans, etc. Automatic cleaning & grading procedure adopts dual vibrating motors, rubber shock absorber, different sizes of sieves and rubble balls. Materials are vibrated along sieving deck which has multi-layers, then are graded to different levels by size, while oversized and under sized impurities get removed. Customized various screen mesh and amount of sieve layers that make the vibrating grader has wide range of applications and high grading efficiency. Carbon steel or stainless steel can be chosen for quality standard of the screen materials. The product is installed behind the colour sorting machine for a final quality control, or in front of the seeds shelling machine for pre-cleaning. An optimal design, efficient grading operation and compact structure makes it an ideal grading equipment.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Double stream mills are used to grind core layer akes or course material rejects from screening processes to ne surface layer akes. In the wood-based materials industry they are the ideal solution when it comes to the further renement of akes. The produced ne akes are used in surface layers for particleboard, for example, in the furniture industry. Surface layer mills are part of a reliable machine technology. In the renement process of akes, which were primarily produced with knife-ring akers type PZKR, these mills produce high-quality surface layer akes Features, Function material feed via vibrating chute heavy-particle and magnetic separator pneumatically supported transport of the ground material inside the machine size reduction between beater plates and grinding segments selectable grinding track geometry interchangeable screens with dierent mesh sizes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HEATION AB

Sweden

optimum is a strainer filter. The housing is manufactured in stainless steel and available in 3 different constructive shapes Y, L and O to adapt to various installation types. The filtering element is a mesh screen. It is the optimal solution to be implemented as a protection filter in closed-circuit plants and more in general in process water applications with a moderately low quantity of suspended solids.

Request for a quote

OFFICINE CONTERNO SRL

Italy

The professionalism of Officine Conterno does not end with the design and construction of machines and plants for aggregate and waste processing, but also extends to after-sales. For all machinery maintenance and repair needs, Conterno provides an efficient technical assistance service, which is able to provide for the rapid and complete recovery of your plant at both structural and functional level. We are also able to provide replacement parts for all types of aggregate processing machines, all of which are certified and guaranteed. The following is a list of the main spare parts supplied by the company, including for machines of the leading Italian and foreign manufacturers: • Jaws • Armour for mills and crushers • Hammers for mills and crushers • Steel meshes • Polyurethane meshes • Rubber meshes • Bearings for screens • Rubber mats • Scrapers • Rollers • Drums • Gearboxes for belts ... and many other mechanical parts for all types of machine.

Request for a quote

PRODEV ENGINEERING

Turkey

Inclined screens are very important for all mineral processes. The process of grouping the bulk material containing pieces of different sizes in at least two size ranges is called screening. The screening process is referred to as the "classification process" in mineral processes. Screening panels with specific sizes of mesh are attached to the screen body. While the fed material moves on the screen panel with the vibration of the body, the pieces smaller than the mesh gap pass to a lower screen panel with a smaller mesh size to be screened again.

Request for a quote

KESTASMAK MINING MACHINERY AND SPARE PARTS

Turkey

jaw crushers, primary impact crushers, secondary impact crushers, dewatering systems, screens, vertical shaft impact crushers, VSI, VSI spare parts, crusher wearing parts, feeders, bunkers, conveyor systems, conveyor belts, conveyor rollers, conveyor drums, belts, clamps, high carbon steel woven meshes, anti clogging, anti-clogging screen meshes, flex screens, perforated steel screens, bolts, polyurethane screens, polyurethane tensioned screen panels, polyurethane jig screens, polyurethane dewatering screens

Request for a quoteResults for

Screen mesh - Import exportNumber of results

10 ProductsCompany type