- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- saw mills

Results for

Saw mills - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Drop lubrication of cutting tools at machining work on ferrous and non-ferrous metals, for example during drilling, thread cutting, sawing, milling, punching and nibbling Advantages and benefits Reduces friction and required force Permits high continuous load and higher cutting speeds Allows optimal cutting surfaces Extend tool lives through reduction in wear Neutral behaviour toward machine coatings Free of chlorine and heavy metals Low tendency to form oil mist Apply a sufficient quantity of OKS 390 to the tool or machining point using a brush, drip oiler or oil can. Spray on sufficiently OKS 391 spray. After use OKS 390 can be removed with OKS 2610/OKS 2611 universal cleaner. Caution: Check compatibility before using on non-ferrous metals.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Drop lubrication of cutting tools at machining work on ferrous and non-ferrous metals, for example during drilling, thread cutting, sawing, milling, punching and nibbling Advantages and benefits Reduces friction and required force Permits high continuous load and higher cutting speeds Allows optimal cutting surfaces Extend tool lives through reduction in wear Neutral behaviour toward machine coatings Free of chlorine and heavy metals Low tendency to form oil mist OKS 390 is suitable for use with the OKS Airspray system Also available as spray version OKS 391Apply a sufficient quantity of OKS 390 to the tool or machining point using a brush, drip oiler or oil can. Spray on sufficiently OKS 391 spray. After use OKS 390 can be removed with OKS 2610/OKS 2611 universal cleaner. Caution: Check compatibility before using on non-ferrous metals.

Request for a quote

ANTON SCHIMMER & CO GMBH

Germany

Toy Components & Game Accessories As a long-standing supplier of well-known toy and game manufacturers in Germany and abroad, we fulfill the highest quality standards. All used stains, paints and colors of course comply with DIN EN-71 for children's toys. We manufacture standard articles made of wood, as well as custom-made products according to your wishes and ideas - turned parts, milled parts, sawed parts: Dice from Ø 14 to 60mm Tokens Pawns Checkers Backgammon dice

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The patented casting resin system ALWA MOULD D consists of two resin components and an aluminium filler. The fast curing of the material allows to produce your own technologically highest quality moulds in just a few hours. As our material is very good castable, compact moulds of any desired volume can be made from our product, such as acrylic baths, boats, etc. (<1 kg – 2500 kg). In comparison to other materials (e.g., glass fibre reinforced plastic), the system is more temperature-resistant, allows castings without air bubbles and does not have to be post-cured. Furthermore, the finished mould is easy machinable (e.g., drilling, milling, grinding, planning, sawing, turning, etc.). ALWA MOULD D moulds can be modified with repair filler, so that a fresh view can be created at an early stage of a new design process and prototypes can be examined at short notice.

Request for a quote

AMS TARA SP. Z O.O

Poland

At sawmills in Poland and Eastern Europe, we produce all kinds of pallets, including lids and legs of coniferous and deciduous wood. You can order almost any wood product from us, including crates, wedges, coils, etc. At your option, we can perform additional operations such as milling, chamfering, corner sawing, notching. We also do wood drying and IPPC processing with all certifications and possible confirmations.

Request for a quote

ALUMAX

Greece

Alumax, also, offers final parts of a high quality level in competitive prices. We produce medium and even small batch size components, at short lead times, using our customer’s own drawings or samples. For this purpose, we have invested in modern machinery, such as CNC milling machines, sawing centers and punching & drilling center. Sawing Drilling Milling (from small parts up to 6m bars) Turning (up to a diameter 250mm and a length 800mm) Laser cutting Shearing Forming Punching Laser engraving The above processes, if appropriate, are followed by joining the parts together or with glass, plastic, etc., by welding, bolting, riveting or binding with adhesives.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

We excel in CNC processing focused on precise milling, therefore we can offer you advanced custom milling parts. We specialize in CNC aluminium processing and milling of plastic materials. In the machine park there are 3- and 5-axis simultaneous CNC machining centres that ensure to satisfy even the most demanding clients. By our client’s request we provide surface treatments. Dimensions of flat workpieces can be up to 860 x 500 mm. Our machine equipment: -HAAS UMC 750 SS - 5-axis simultaneous CNC milling -HAAS VF2 SS - 3 + 2 axis CNC milling -HAAS VF2 - 3 – axis CNC milling -Saw - Pegas Gonda 290x290

Request for a quote

LEICA MICROSYSTEMS

Germany

The Leica EM TXP is a target preparation device for milling, sawing, grinding, and polishing samples prior to examination by SEM, TEM, and LM techniques. An integrated stereomicroscope allows pinpointing and easy preparation of barely visible targets.

Request for a quote

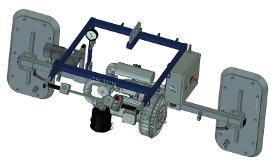

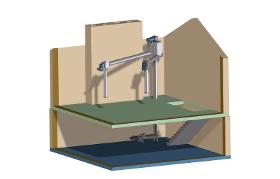

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

How do you normally transport large OSB or particle boards? That usually requires multiple employees and work steps in order to transport heavy and bulky goods from A to B. Thanks to AERO-PORO vacuum lifters from AERO-LIFT, such problems are now history! Now your existing crane can be made much more effective by adding an AERO-PORO lifter. The crane operator can now lift, transport, swivel and deposit workpieces all on his own. Safely without damage and assistance. Tailored to your requirements, our AERO-PORO lifters are able to transport very large panels with ease and can even generate a reliable vacuum when handling porous materials. Previous Next Functionality and characteristics Handling, transport and swivelling of hundreds of kilo heavy porous wooden boards in saw mills, carpenters and in the wood and furniture...

Request for a quote

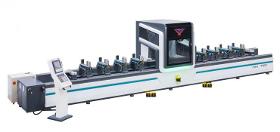

YILMAZ MACHINE

Turkey

AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the six sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time. An additional magazine for the saw blade with 350 mm dia. ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 7510 is 5-axis servo controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminum profiles, light alloys in general and thin walled steel profiles. Efficient and economic processing on the 5 sides of the profiles is possible with this fully automatic machining center. The moveable turret type of tool magazine equipped with12 standard tools provide a fast tool change.It is housed in the mobile gantry to minimize the tool change time.An additional magazine for the saw blade with Ø350 mm ensures the ease of machining on the exterior applications of the profiles. The machine can be used in tandem mode, a work method that allows machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run “while the machine is operating. Automatic clamp recognition and clamp positioning is available.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4310 is 3-axis CNC controlled machining center which is designed for the working of all kinds of aluminum & PVC profiles, light alloys in general and temporary operations of thin-walled steel profiles with special cutters. By means of the additional aggregate tool, various profiles can be machined with 4-axis movement. The machine can be used in tandem mode, a work method that allows to machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run "while the machine is operating. The machine has automatic vise positioning feature (with CAMPROX software) and equipped with magazine unit holding 8 tool-units (second magazine unit optional) with the possibility of placing 2 aggregate tools and 1 milling saw to perform machining on the 5 sides of the pieces. Isolated cabinet reduces the noise of machine and provides safety of the operator. GENERAL FEATURES: • Designed for all kinds of drilling, grooving,...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Drum chippers are used to process long and short logs, wood pieces, saw mill waste, veneer waste, residual wood, and other wood waste to high-quality chips. Depending on the size and design of the drum chipper, the machine can be adjusted to the type of wood to be processed and the desired chip quality. The most suitable chipper size is determined by the maximum trunk diameter to be processed and the desired production capacity. The desired chip length also inuences the performance of the chipper. Key features Adv Large draw-in rollers for process-reliable wood feed at constant speed Pivoting feed system for automatic adjustment to loading height Hydraulic ywheel drive for consistent contact pressure and the damping of impacts Robust, well-balanced rotor Large ywheel inertia to compensate for short-term peak loads Generously dimensioned V-belt drive Startup process via Pony-motor to reduce spikes in power supply during acceleration of the rotor

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our high-performance machining oil SENTOS V-LR3 has a somewhat higher lubricity compared to our SURVOS products. This product also consists of volatile components that evaporate down to a lubrication residue of 3%. All components are approved according to USA-FDA §178.3910 as surface residues for the manufacture of food packaging. This makes our SENTOS optimally suited as a lubricant and drawing agent for punching and deep drawing (even with high contact pressures), for cutting and perforation of sheets (aluminium, steel, copper, brass, zinc-plated), including transformer and electric sheets, as well as for painted and coated sheets in particular. In addition, our SENTOS is especially well suited for cold profiling, bending and embossing, as a cooling lubricant for sawing, drilling, milling and engraving as well as a lubricant for cutting non-metallic materials.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Technical plastics for industry are a further speciality of IBK. We produce plastic parts to your specifications (ISO, CAD, drawing) for all temperature ranges and with specific chemical resistance. Whether unusual, complex or just simple forms – we turn, inject, saw, drill or mill, whatever you require. We supply semi-finished products as round bars, plates, pipes, rods, profiles or individual cuts, rolls, rollers or wheels with or without coating. Furthermore finished parts, such as protective systems for safety at the workplace in electronic applications. We process all types of plastic, from polyamide to hard PVC through to GRP/FRP. Semi-finished parts: Plates, Blocks, Full rods, Hollow rods, Pipes, Cut pieces Finished parts Cut and processed (turned, milled, drilled etc.) to drawing, sketch or sample, such as - Wheels, Rollers, Bearing bushes, Thrust rings, Bands, Sleeves, Strips

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We offer PU sheets in the dimensions 3000 x 1000 mm and thicknesses from 1 to 50 mm. Of course, special dimensions are also possible. PU round bars are available in the dimensions 70 °, 80 ° or 90 ° Shore A, dimensions 8 200mm x 1000m. Intermediate sizes can also be requested here. In addition to the extensive range of semi finished products such as plates, round rods, hollow rods and spring elements, molded parts with and without metal are also included in the scope of delivery. Mechanical rework such as water jetting, milling, drilling, sawing, punching and welding offers flexible potential from individual parts to series production. Possible Shore hardnesses from 55 ° 95 ° Shore A.

Request for a quote

HF HAYTEK PLASTIC AND PLASTIC MACHINERY CO.

Turkey

Planetary saws, equipped with disk and milling cutter for cut and chamfering of PVC pipes (rigid and foam) or other plastic materials; Swift replacement of tools, even with pipe in movement; Pipe blocking vices or iris mechanism jaw system. Suction device with double filter and sound-proofing; Automatic synchronisation with extrusion speed.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteResults for

Saw mills - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Woodworking - machinery and equipment (17)

- Silicones (2)

- Finishing of surfaces - machinery (1)

- Lubricants, industrial (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Milling - steels and metals (1)

- Pallets (1)

- Plastics - industrial products (1)

- Rubber products (1)

- Tubes and pipes, rubber and plastic (1)

- Turbine drilling services (1)

- Wood veneer - machinery and equipment (1)