- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sandblasting

Results for

Sandblasting - Import export

MEGA-METAL D.O.O.

Slovenia

We use our blast chamber and well-trained staff to sandblast our own welds and clients casts.

Request for a quote

BLASQEM, LDA.

Portugal

Natural garnet sand is a non-active mineral abrasive which does not cause silicosis. It has high performance, ensuring efficiency and economical process with medium oxidation level. Its grains are microcrystalline, with more or less irregular rounded shapes. Hardness: 6-7.5 mohs Shape: irregular Density: 3.5-4.3 g / cm3 Welcome to BLASQEM, your Specialist in Shots, Abrasives and Equipment: - Abrasive Products and Accessories - Abrasive steel shots - Abrasives manufacturer - Abrasives solutions - Blasting material - Metallic shots and organic media or glass sandblasting and aluminium oxide or carbon grit abrasive shots for shot blasting - Steel Abrasives and aluminium shot for shot blasting operations - Blasqem is the industry's leading supplier of industrial abrasive

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Blasting is a structure-generating process for matt or satin-gloss surface structures. Small surface imperfections in the material can be concealed by the abrasive effect of stainless steel balls, which hit the material with the help of air pressure. Hand blast cabinet MHG Maximum measurements 2000 x 1000 x 1000 mm Blast cabinet Maximum measurements 400 x 400 x 200 mm

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

Special features of our model range SUPER BABY: • Compact and elegant design • Simple operation • Low material consumption • Highly efficient dedusting • Efficient function • Environment-friendly function without dust harassment • Adjustable material consumption The SUPER BABY has a large door that opens to the top and allows to put in the work pieces easily. Due to the mounted sinkhole the blast media circulation is possible without any other additional equipment. With the controls to adjust the blast media it is easy to adjust the blast-media consumption and to change the blast media type. A built-in nozzle-holder and an injector type blast-head with hardened air- and blast nozzle (manual operation), as well as a working grid allow an easy operation. A Shock-resistant linear fluorescent luminary gives glare-free light in the work area. Efficient injector sandblasting booth Superbaby. Direct from manufacturer, MADE IN GERMANY.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The Modellrange ECONOMIC is made of durable sheet steel. It comes with adjustable media consumption, a blast media collection bin and a sieve to separate blast media from contaminations. The cabinet has two lateral openings with sealing sliders for rod materials. A perforated metal plate with enforcements. The system has a sectional door that opens the complete workspace. The Cabinet comes with a door-safety switch, two large operation holes with multiple rubber Sealings. Monitoring window, sized 400x500 mm, with easy changeable glass/safety-glass panes, as well as 2 durable pneumatic springs. Energy Saving Lamp, attached from outside. Injector-type blast head, with air- and blast nozzle made of hardened steel. The system comes with all necessary compressed air and blast media hoses, oil-water separator, manometer, an electrical magnet valve and a foot switch. On/Off switch, dust filter system 0,55 kW, intermediate pressure turbine. Dust collection bag.

Request for a quote

OZCETE KARO

Turkey

-Resistant to corroding and impacts -Wide pattern alternative -Add high value to the spaces -Can be used as wall covering The terrazzo tiles with sandblasting are produced with a special upper surface process applied on surfaces of tiles. Therefore they are special products from both esthatical and technical aspect. The most significant property is that does not cause skid.

Request for a quote

BV SRL SHOT BLASTING AND WASHING MACHINES

Italy

The main feature of the BV shot blasting equipment is the long resistance and duration in time of the machines that are constructed with special steel abrasive to the great thickness Manganese (fundamental characteristic for a shot blasting plant), equipped with single-disc turbines technologically advanced (built with materials wear-resistant cast iron Ni-Hard), and mechanical and electrical components Heads first level.

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Pressure-blasting boilers that can be used as portable are a type of sandblasting machine that can be managed by an operator and can be conveniently kept by the operator in open areas. Portable sandblasting machines are capable of blasting with all kinds of granules and are controlled by a remote pneumatic trigger. It is preferred for sandblasting large parts, vehicles, and steel constructions. Although the portable sandblasting machines produced by BF BLAST operate at 6-8 bar, they are put into production after being tested with 22 bar pressure water and passing quality control.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine in which the sandblasting process is carried out with the turbines in a row on one side while being rotated by the automatic suspension system on the machine after it is placed in the hanger baskets on the workpiece. It is preferred in metal manufacturing sector and spare parts revision processes. The machine can be optimized in line with the needs and demands.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Sandblasting Cabinets are designed for dust-free sandblasting of small and medium-sized parts in the cabinet. Air consumption is less compared to pressurized cabins. Thanks to the cartridge filter coupled to the back of the cabinet, a clear view is provided during sandblasting. Steel grit/steel ball-like granules are not used in vacuum blast cabinets! Only suitable for use with aluminum oxide, silica, garnet, glass ball, and plastic granules!

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Usually, marble, basalt, granite, etc. natural stones; It is a type of sandblasting machine used for aging, anti-slip, or decorative sandblasting. It is called a marble sandblasting machine because of the need for sandblasting of marble more commonly than other stones. It can be preferred without hesitation for sandblasting all-natural stones.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine in which the placed parts are sandblasted with the rotation of the horizontally positioned circular table. It is preferred for sandblasting medium-sized parts that are not suitable for hanging.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine produced for the purpose of sandblasting the outer surface of pipes, tubes, shafts, and similar materials. The outer surface of the diameters of 20mm (1/2”) to 3048mm (120”) pipes can be sandblasted with a pipe blasting machine. You can contact our sales representatives for in-pipe sandblasting solutions. Pipe blasting machines are produced with different equipment according to the needs, and some standard dimensions are as follows:

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Sandblasting cabin also called Shot Blasting Room; It refers to the closed sandblasting area in which sandblasting is carried out with the labor of one or more operators. Sandblasting rooms: It consists of the Cabin, the Sandblasting System, the Recycling System that allows the used sand to be reused, the Ventilation & Filtering System and the Control Panel. It is mostly preferred for sandblasting a large number of parts that do not require a large and automatic machine. Automotive, Steel Construction, Defense Industry etc. preferred in the sectors. Standard sized sandblasting chambers are shown in the table below, although they are produced by BF BLAST in all sizes according to customer needs.

Request for a quote

KRANAMAX

Bulgaria

Preparing surfaces for painting/coating.

Request for a quote

SEVAL S.N.C.

Italy

Sandblasting the glass to reduce its transparency or to embellish it with shapes/designs/symbols. Can be combined with other processes such as silvering and decoration.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

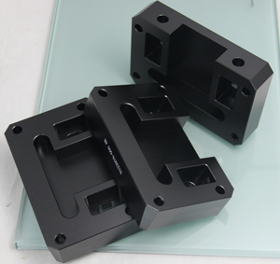

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in precision machinery,after processing, local sandblasting is carried out.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are milled by aluminum,which used in architectural decoration industry.

Request for a quote

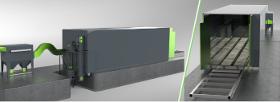

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Steel construction, metal, etc. with a high production capacity. It is the type of sandblasting machine preferred by companies in the production sector. The conveyor system is designed as trolleys carrying hanger hooks on a linear line. Different conveyor types are preferred according to light and heavy materials.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Pressure Shot blasting cabinets are designed for small and medium blasting in the cabin by talking in a way. They perform faster sandblasting than sandblasting cabinets and can be used with any type of sand. It is envisaged as an integrated state of pressure boilers and vacuum-blasting cabins. Thanks to the cartridge filter coupled inside the cabin, a clear view is provided during sandblasting and the jet-pulse system filter is automatically cleaned with the air used. Words sandblasting cabinets produced by BF BLAST according to needs; They can be optimized as rotary tables, drums, and double doors. The table below shows the types of vacuum cabinets

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is the preferred blasting machine for blasting unnecessary materials that do not have bumps while blasting together. Parts can be sandblasted together or separately. While driving the rubber band pieces rotating between three different drums, the sandblasting process takes place with the turbine located at the top.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® MT micro blasters are used for precise blasting with blasting nozzles from 0.4 – 1.8 mm. Surfaces can be smoothed, matted, deburred or cleaned. All mineral media, e.g. glass beads, broken glass, corundum, silicon carbide in the grain size range from 0 to 300 mμ serve as blasting media. The abrasive is used only once. The blasted surface is reproducible. Only a compressed air connection is required to operate the equipment. Micro-Tip fine blast units are suitable as portable free blast units or in combination with a blast cabinet. Micro-Tip fine blasting technology is available as a pressure or injector process. All units are equipped with foot pedal, pressure regulator, manometer and carbide nozzles.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-BB blast cabinets with combined blasting and blow-off function (Blast´n´blow®) and ex-protection accord. to 1999/92/EC for paint stripping and surface decoating in seconds. Fine organic blasting media get shot onto the workpiece by compressed air, whereby even stubborn thick layers are loosened in shortest time by the effect of the soft, but sharp-edged granulates. Even sensitive tool surfaces get not damaged. The blasting process is suitable for the removal of all solid, exposed residues, especially on metallic surfaces of production tools and high-quality machine parts. Blasting granulate and blasting pressure are adapted to the respective application. With the pressure blasting process you can clean extruder and injection moulding screws, blowing heads, moulds and profile tools much faster and more gently than with conventional cleaning methods. In extensive tests with your own workpieces you can convince yourself of the economic efficiency of our system.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DI-EU injector blasting cabinets are designed for use in production and maintenance. Ready for use equipped with integrated cartridge filter and abrasive recovery system. Economical operation with fine-grained abrasives with low air consumption of approx. 800 l/min. at 6 bar blasting pressure. The blasting media is continuously sucked out of the cabinet by a constant negative pressure and separated from dirt and dust in a downstream cyclone. A cyclone screen (possibly with ring magnet) collects coarse impurities. In this way, only clean abrasive remains in circulation. The used abrasive, dust and small impurities are led through the cartridge filter chamber to the dust collecting bucket.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-EU pressure blasting cabinets clean and process tools and parts in just a few seconds. Fine blasting granulates are shot onto the surface by means of compressed air and remove dirt and corrosion. The blasting nozzle is manually guided during the processing of individual parts. Process automation is also possible. For this purpose, the workpiece or the blasting nozzle is moved by motor. The pressure blasting process is suitable for the removal of all solid, exposed residues and layers, especially on metallic surfaces of production tools and high-quality machine parts. Deburring and finishing of surfaces is also possible. In extensive tests with your tools you can convince yourself of the economic efficiency of our system. We will provide you with a test facility for this purpose after consultation.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quoteResults for

Sandblasting - Import exportNumber of results

82 ProductsCountries

Company type

Category

- Sandblasting equipment (47)

- Steels and metals - surface treatment and coating (8)

- Surface treatment - machinery and equipment (7)

- Jackets, leather (2)

- Sand blasting - steels and metals (2)

- Shot blasting - steels and metals (2)

- Agriculture - Machines & Equipment (1)

- Bicycle frames (1)

- Chains, iron and steel (1)

- Coating machinery (1)

- Cutting - machine tools (1)

- Fittings, pipe, tube and hose - plastic (1)

- Furniture and decorations, garden (1)

- Glass (1)

- Glass constructions (1)

- Greenhouses, indoor (1)

- Industrial cutting machine tools (1)

- Mechanical surface treatment - machinery (1)

- Monitoring and control equipment (1)

- Natural abrasives (1)