- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- unit design

Results for

Unit design - Import export

ZBKIT LLC

Russia

One-plunger pumping units PT 1.1 with capacity up to 8 m3/h and pressure up to 40 MPa Three-plunger pump units according to API 674 (3-d edition) PT 1.3 and PT 2.3 with a capacity of 0.2 m3/h to 60 m3/h and pressure up to 80 MPa Five-plunger pumping units Pumping units are designed for pumping various liquids, including chemically active ones, with temperatures from -15 ° С to + 450 ° С, kinematic viscosity of not more than 8 cm / s, with the content of solid non-abrasive particles up to 0.2% by weight and size up to 0.2 mm.

Request for a quote

PKO-SURA COMPANY

Russia

Depositors (extruders) are custom-manufactured depending on the needs of the Customer and the parameters of the oven. All projects are coordinated with the Customer and the oven manufacturers. The machine frame is manufactured in the following types: •U-shaped frame; •frame of intermediate section; •frame mounted in the oven tension station. Mechanisms and units of machines are specially designed considering the increased operating temperature and continuous equipment operation throughout the day. (for making various types of cookies, gingerbread, etc.)

Request for a quote

IRIDA LLC (UFANET GROUP)

Russia

Unit for rolling out the optical single-fiber cable d400. Designed for rolling out optical cable from the coil. Material: metal. Subscriber patch cord modular Roll-out unit d370 Ufanet. Designed for rolling out optical patch cords. Material: metal. It is installed on a hard surface Roll-out stand Cable roll-out unit for patch cords (connector 115*370) Ufanet. It is used for coils with dimensions of 290*107mm. Material: metal. Designed for installation in the ground

Request for a quote

VILLINA LLC

Russia

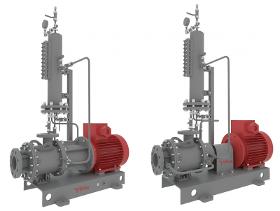

Horizontal canned pumps with welded bodies (Villina-GNGC) are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These pumps are used in petrochemical, petroleum refining and other industries. single-stage or multi-stage version of the unit design (increased discharge pressure, in contrast to back pull-out pumps); high efficiency of the impellers; a possibility to pump contaminated liquids with 100% tightness (for pumping units with combined seals); Temperature of the pumped fluid: up to +420°С.

Request for a quote

VILLINA LLC

Russia

Villina-GNVCP-2T type vertical electric semi-submersible pumping units are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These are used in gas, petrochemical, petroleum refining and other industries. The vertical semi-submersible pump – the pump part is fully or partially in the pumped liquid. The unit consists of a pump part, drive sections, a base plate, a device that transmits torque from the drive, an electric motor (drive). The ground part comprises a console fastened to the base plate, an electric motor mounted and fastened to the console, and a mechanical seal support system fastened to a base plate. The semi-submersible part comprises drive sections fastened to the base plate, an elastic coupling body connected to the lower drive section, a pump connected to the elastic coupling body and a discharge line.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEYSER LLC

Russia

A washing unit with manual cleaning designated for complex cavities, soot dirt and carbon deposits. It is guaranteed to remove: cooling mixtures, dust, shavings, composites, oils after stamping, rust-preventing grease, polishing compounds, emulsions, oil products, sweat and grease deposits. The unit allows you to clean parts with complex cavities. A washing unit is equipped with a pneumatic drive for connecting a pneumatic brush and an air gun, as well as a flexible hose for supplying water under pressure.

Request for a quote

GEYSER LLC

Russia

The most efficient model of washing equipment designed for continuous processing of parts. It may include washing, rinsing and drying units. The washing unit is equipped with a conveyor, a control cabinet, an assembly compartment, an oil separator, tubular electric heating element, a temperature sensor and a solution level meter. The conveyor speed is individually adjustable and can reach several meters per minute. The unit is designed for surface treatment by high pressure water jets to remove oil and grease contaminants, fine chip, cooling mixtures, and coked-free sand and dust deposition. The installation fully meets modern requirements applicable to the parts, components and assemblies washing technology. The unit is intended for indoor use.

Request for a quoteResults for

Unit design - Import exportNumber of results

8 ProductsCompany type

Category

- Pumps (2)

- Industrial washing facilities (2)

- Surface treatment - machinery and equipment (2)

- Bakery - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Confectionery - machinery and equipment (1)

- Information technology - cabling (1)

- Pump-driven power stations, installations and equipment (1)

- Scouring - steels and materials (1)