- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pump shafts

Results for

Pump shafts - Import export

VILLINA LLC

Russia

We produce shafts for pumping units made of the following materials: steel 20H13, 30H13, 40H13 as per GOST 5632-2014; GOST 5949-2018; 14H17N2 as per GOST 5949-2018. Shafts made of other materials are also available subject to prior agreement. Subject to preliminary agreement, we are able to supply larger diameter shafts. All parts are manufactured according to drawings.

Request for a quote

VILLINA LLC

Russia

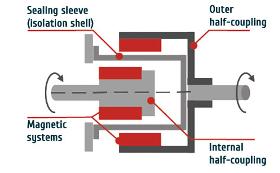

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

VILLINA LLC

Russia

The design of an electric pump section is similar to the design of a standard vertical electric pump with a GNVC series magnetic coupling, which allows for the use of already proven technical solutions: impeller blades with curved surfaces create an angle of attack and partially allow for switching to the laminar mode of wall-adjacent flow on their surface and provide more efficient deflection of liquid to the periphery; a closed type impeller has a higher efficiency and longer service life compared to open and semi-closed impellers; bell-type fit of the impeller on the pump shaft precisely keeps the geometric position of the impeller with respect to the guide vanes; the vertical position of the shaft resting on a heavy-duty carrying cushion in the vertical plane, and sleeve type bearings in the horizontal plane help prevent sagging of the shaft, as for instance, in the horizontal design of the pump, and play and runout; the use of sleeve type bearings

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pump shafts - Import exportNumber of results

4 ProductsCountries

Company type