- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical seals

Results for

Mechanical seals - Import export

VILLINA LLC

Russia

Our products include Villina-GNGC-2T type centrifugal horizontal pumps with tandem mechanical seals type according to your parameters. These are used for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. The units are mainly used by petrochemical industry companies. Parameters of operating fluids (liquids): temperature from -50oС to +400oС viscosity up to 160 cSt density 2,000 kg/m3 max, with a high concentration of particles particle size over 0.2 mm, but not exceeding free passage of the impeller (3 to 12 mm depending on the pump rate) For such conditions, mechanical seals (operating temperature up to 425°C) of well-known companies are used, such as: OOO NPC ANOD, JSC TREM ENGINEERING, UNICHIMTEK Group of Companies and others DESIGN FEATURES The unit consists of a pump, a base plate, an electric motor, a casing and a support system.

Request for a quote

VILLINA LLC

Russia

Villina-VS1-M type pumps are designed for use in oil and gas and chemical industries for transit of explosive and highly flammable liquids as well as corrosive media and natural gas liquids. A distinctive feature of these pumps is the ability to transit contaminated liquids with particle size of 3 to 12 mm (depending on the pump rate). MAIN SPECIFICATIONS - Pump rate ranges: 2 to 108 m3/h; - Head: 11 to 178.5 m; - Temperature of the pumped fluid: -50°С to +440°С.

Request for a quote

VILLINA LLC

Russia

Villina-GNVCP-2T type vertical electric semi-submersible pumping units are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These are used in gas, petrochemical, petroleum refining and other industries. The vertical semi-submersible pump – the pump part is fully or partially in the pumped liquid. The unit consists of a pump part, drive sections, a base plate, a device that transmits torque from the drive, an electric motor (drive). The ground part comprises a console fastened to the base plate, an electric motor mounted and fastened to the console, and a mechanical seal support system fastened to a base plate. The semi-submersible part comprises drive sections fastened to the base plate, an elastic coupling body connected to the lower drive section, a pump connected to the elastic coupling body and a discharge line.

Request for a quote

VILLINA LLC

Russia

Villina-VS1-М, Villina-GNVC-K and Villina-GNGC-K type centrifugal canned pump units with combined seals are widely used in modern gas industries, petrochemical and petroleum refining industries. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. For such conditions, mechanical seals with operating temperatures up to 425°C of well-known companies are used, such as: OOO NPC ANOD, JSC TREM ENGINEERING, UNICHIMTEK Group of Companies and others, as well as permanent magnets (SmCo) with operating temperatures up to 450°C. Villina type units are made in three versions as regards the spatial location of the pump rotor: vertical ground-level (Villina-VS1-M) - the pumped liquid is supplied to the pump part of the unit through a suction pipe located radially to the pump rotor. The unit consists of a pump part, a device

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

VILLINA LLC

Russia

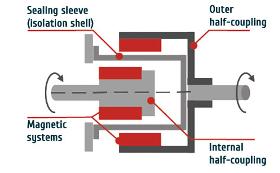

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mechanical seals - Import exportNumber of results

6 ProductsCountries

Company type

Category