- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotor seals

Results for

Rotor seals - Import export

PEEKCHINA CO., LTD.

China

Our PEEK rotor seals are precision-engineered to deliver superior chemical resistance and mechanical strength. Designed for use in demanding applications like HPLC systems and other analytical instruments, these seals provide excellent durability and leak-free performance under high-pressure conditions. Their unique design ensures smooth operation, minimal maintenance, and extended equipment life, even in aggressive chemical environments. The combination of PEEK's high-performance material and advanced engineering makes them a reliable choice for critical laboratory applications.

Request for a quote

MIX SRL

Italy

Main features • Short mixing time • High mixing quality • Batches with repeatable results • Gentle mixing • Low maintenance Techanical features • Batch size: from 80 to 35.000 liters (net) • Through "U" shaped mixing chamber • MIxing tools: four ribbons, opposed two by two • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door on the top flat cover, complete with sfaty grid and electric block • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Request for a quote

MIX SRL

Italy

Main features • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Request for a quote

MIX SRL

Italy

Main features • Mixing times adaptable to the specific process • Extremely high mixing quality • Constant quality of the product output • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance Techanical features • Hourly productivity: from 500 to 1.200.000 liters/h • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door complete with safety electric lock • Vertical discharge door with adjustable internal diaphgrams to regulate the production capacity • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Request for a quote

MIX SRL

Italy

Main features • Management of the process time and temperature through the heat exchanger • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen • Heat exchanger on mixing chamber for heating / cooling processes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIX SRL

Italy

Main features • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance • Easy deep cleaning Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Full access to mixing chamber through the extractable rotor shaft • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow precision volume dispenser eco-PEN 300, made by ViscoTec, is ideally suited for dosing tasks with low to high viscosity materials (e.g. dosing of adhesives, fluids or pastes). The proven ViscoTec endless piston principle, which is based on an progressive cavity pump, is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. Due to the controlled rotary movement of the rotor, delivery is generated by displacement of the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium break-off without dripping. Application: Whether dot dosing, with highest volumetric accuracy, most precise bead application with application speed adjustable to the application speed or in potting technology - preeflow means micro dosing in perfection.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The precision volume dosing unit eco-PEN600, made by ViscoTec, enables many applications in the low to medium viscosity dispensing range. It is ideal for dosing grease, paint, sealants, adhesives, oil, silicone, generally abrasive media and many other materials. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The innovative precision-volume-dispenser eco-PEN700 made by ViscoTec offers a wide range of applications for low to medium-viscosity dispensing. preeflow® eco-PEN is a rotating and perfectly pressure-tight displacement system. Self-sealing rotor/stator design. Conveyance action by medium displacement in the stator through controlled rotor rotation. Safe conveyance without any modification of the medium. With its suck back option, preeflow® ensures clean and controlled material or medium cut-off while preventing post-dripping effects.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The eco-PEN330 precision volume dispenser made by ViscoTec enables many applications in the low to high viscosity dispensing range. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. - True volumetric dosing - Retreat effect - Viscosity-independent dosing - Easy cleaning - dosing independent of inlet pressure - Adjustable dosing flow - Pressure-tight without valve - Dosing pressures from 16 to 20 bar

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Examples of materials for dosing: 1- and 2-component epoxy, UV / light-curing / thermosetting adhesives, highly filled materials, anaerobic adhesives, shear-sensitive adhesives, heat-conducting paste, sealants, flavourings, silver conductive paste, flux, perfume, isopropanol, industrial oils, silicone, alcohol, grease, paint and ink, MEK, braze paste, PU, acetone, petrol and many others. The preeflow® eco-DUO is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. Application: - point dosing, with highest volumetric accuracy - bead application with application speed adjustable to the web speed - Potting technology

Request for a quote

CLIXAR

Ukraine

The Lumiseal twist seal is made of polycarbonate and consists of two pre-installed parts: the case and the rotor with catches featuring the unique number. It is applied by laser, which virtually eliminates the threat of counterfeiting or replacing the seal number. The rotor of the seal can only be rotated clockwise, so you can be sure that once the seal is installed, no one can open it without leaving visible signs of tampering. An additional degree of protection is marking applied by laser through the thickness of the seal surface. Thus, it cannot be erased, removed, or counterfeited. The unique number is applied on the case and the inner rotor, so no one can replace any part of the seal. Additionally, your company logo, QR, and bar codes can be marked on the case catch.

Request for a quote

OMAC SRL

Italy

The B series lobe pumps satisfy most transfer applications to suit hygienic and chemical characteristics. OMAC'S lobe pumps are appreciated all over the world for stoutness and performances, assures good services, long endurance, easy and cheap maintenance.This range consists of 16 models with deliveries from 0.05 to 200 m³/hr with the following versions available ST Model with standard tolerances, SM Model with increased tolerances, both being made in AISI 316 stainless steel and both available with Duplex shafts. HP Model has crescent shaped rotors in antiseizure stainless steel alloy with shafts in Duplex for counter pressures up to 20 Bar. The OMAC Lobe Pump is modular in design allowing the main parts such as the rotor and seals, to be changed quickly and easily. A wide range of rotors, seals and gaskets is also available.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers finished or semi-finished parts directly formed from polyimide powder with all the attributes of sintered PI. The advantage of direct formed parts are the lower costs as quantitiy is increasing. Due to almost zero percent waste during production it can be a more economic production method. Machined parts are widely used for small series high precision applications. Polyimide direct formed parts can be used in different applications: Automotive industry: racing engine fuel line. Jet engine: vane bushing or lock nut insert. Industrial machinery: hotrunner systems nozzles or plasma cutting torch as gas distributers or sealing components. Semicon HDPCVD Equipment: e.g. heater coil spacer. Life sciences: rotor seal or pneumatic surgical tool vane.

Request for a quote

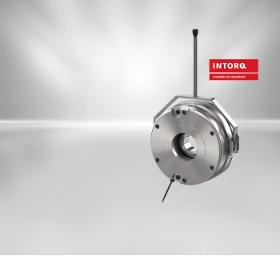

KENDRION (VILLINGEN) GMBH

Germany

When operating in crane and port facilities, a braking system must primarily be reliably protected and, secondly, must operate very powerfully. The INTORQ BFK 471 product series combines these two features perfectly. These specially sealed brakes have a newly designed hand-release mechanism which, like the brakes themselves, is IP66 compliant. This series also features high braking torque and requires only a compact installation space.

Request for a quoteResults for

Rotor seals - Import exportNumber of results

16 ProductsCountries

Company type