- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotating seals

Results for

Rotating seals - Import export

IGUS® GMBH

Germany

iglidur® sealing lip bearing d1 [mm]: Quick and easy-to-mount polymer bushing made of iglidur® J (JDSM) or iglidur® V400 (VDSM) with clip-on radial shaft seal ring as sealing for the rotating shaft. Seals off against dirt, dust as well as all pressure-less media. Polymer bushing with clip-on radial shaft seal ring Sealing for rotating shaft Temperature application range like iglidur® J Coefficient of friction only 10% higher than in iglidur® J Coefficients of friction identically exceptional like iglidur® J Reduced installation space as well as easy and simple mounting Realizable with numerous sealing types High-temperature option VDSM possible Temperatures till 150° C Material: iglidur® J High temperature option VATM, iglidur® V400 Seal ring made of fluorelastomer Bearing-sealing combinations for other applications on request When to use it? When the penetration of dirt and spray water should be prevented When only a small installation space is available in the axial direction When an existing seal should be integrated in a plain bearing When not to use it? When pressurized media should be sealed When absolute impermeability to the shaft and housing is needed continuously We'll gladly do the developing with you iglidur® sealing lip bearing d1 [mm]:

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight packaging requirements, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. PE-coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quote

NORELEM FRANCE

France

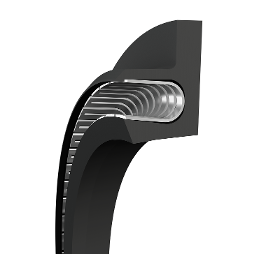

Elastomer NBR. Brace ring and tension spring steel. Rotary shaft lip seals are readytoinstall seals for sealing rotating shafts. They are made from an elastomer outer sleeve and an internal bracing shim. The tension spring ensures increased pressure of the lip against the shaft and supports static sealing. Form A DIN 3760 (ISO 6194/1) version, smooth OD. Form AS DIN 3760 (ISO 6194/0) version, smooth OD with extra dust lip to protect from external dirt. The material NBR has a high wear resistance and is resistant to motor fuels, oil, hydraulic oil and lubricating grease. Operating limits Circumferential speed (m/s) ≤12 Pressure (MPa/bar) ≤0.05/0.5 (rotary shaft lip seals are generally meant for unpressurised operation).

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Compact filling and closing machine for cosmetic products 1-lane machine Direct processing of plastic jars, tins and glasses Machine performance: max. 60 jars/min. Special features: 1 dosing pump with motorised adjustment from 0-500 ml Rotating sealing system for glass jars Integrated screw-top machine with torque shut-off via servo-drive Fully-automatic cleaning of filling machine (CIP/SIP) Film applicator station Rotary station at the filling station (swirl effect)

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

WIND TENSIONERS Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer: Quality Means Lower Life-Cycle Costs: Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts Fully enclosed load cell eliminates debris in piston retraction mechanism Auto-Engaging Geared Nut Rotator Self-energizing, long life seals Enhanced Usability: Piston stroke limit indication High pressure swivel coupling (swivel is optional on WSS & WSL) 19,580 psi (1,350 bar maximum operating pressure) Automatic piston retraction mechanism Designed with Safety in Mind: Overstroke prevention for safe operation Anti-slip grip surface Tool lifting-strap as standard WSS & WSL FOUNDATION WIND TENSIONERS Suitable for ISO Metric threaded and all-thread bars Geared or Manual Nut Rotator Long & short stroke models Maximum operating pressure 19,580 psi (1350 bar) Uses standard system 'nut' for reaction Contact factor for op

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

WIND TENSIONERS Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer: Quality Means Lower Life-Cycle Costs: Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts Fully enclosed load cell eliminates debris in piston retraction mechanism Auto-Engaging Geared Nut Rotator Self-energizing, long life seals Enhanced Usability: Piston stroke limit indication High pressure swivel coupling (swivel is optional on WSS & WSL) 19,580 psi (1,350 bar maximum operating pressure) Automatic piston retraction mechanism Designed with Safety in Mind: Overstroke prevention for safe operation Anti-slip grip surface Tool lifting-strap as standard WDD UP TOWER WIND TENSIONERS Robust Gearbox Drive Auto-Engaging Geared Nut Rotator Small diameter, high load 2-Stage hydraulic load cell Fast application using 1/2" drive Cycle counter optional (Add “A” to end of part number) Max Pressure: 19,580 psi (1,350...

Request for a quote

EUROPEM

Belgium

Rotary kiln incinerators are the workhorse of industry to burn solid waste in combination with sludge, waste gas and/or waste liquids and where the rotating motion transports the solid burning waste through the incinerator. Ashes are collected at the end of the rotating kiln and then combustion gases are completely oxidised in the static post combustion chamber. Rotary kiln incinerators typically feature different types of solid waste feeding systems for the bulky solid waste, containers and drums such as feeding screws and ram feeders. Waste gases and liquids are either injected into the rotary kiln, or the (vertical) post combustion chamber behind the rotary kiln. It provides for flexible and versatile incineration technology, but is characterised by a lower thermal efficiency with the associated higher operating and maintenance costs. Key Features Rotary kiln furnace with pre-set inclination and variable rotation speed. Labyrinth type seal with cooling and/or flushing with inert gas Different feeding systems for solid waste, waste liquids and waste gases Can be operated in a reducing or oxidizing environment Different drive mechanisms such as chain or direct drive, depending on the size of the kiln and the capacity Key Advantages - Robust and flexible design to burn a wide range of waste fractions – Proven technology – Destruction efficiency over 99.999% and less than 3% carbon in the ashes – Low NOx and CO emissions possible – Flue gas treatment train needed to meet acid, heavy metal, dust and PCDD/F emission levels

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

A single-acting sealing element consisting of a U-shaped Turcon® ring and a metallic V-shaped finger spring. The special flanged heel prevents the seal from rotating/twisting and the short and heavy dynamic lip offers reduced friction, resistance to aging and a good scraping effect even in highly viscous media.

Request for a quote

LERAT SPRL

Belgium

Seals to close without pliers. - To use with a special wire - Seals with rotating closure

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

1. NBR shaft seals on hardened cylinder barrels Drum motors axles are usually manufactured from ST37. Commercially available seals rotate directly on the axles. The result, at some point in time, is grooves on the axle. In addition of course oil leaks. This is not the case with the FTK Förderband Technik Kilian pulley motors all drum motors are equipped with hardened and polished cylinder barrels made of stainless steel 316. 2. Oil loss is not a problem for us! Oil change after 50,000 hours of work. Today, for reasons of cost, fewer and fewer users concern themselves with plant maintenance. The maintenance of complex plants is mainly carried out by outside specialists. Simple prefabricated parts, however, are usually used till worn out. This is also the case with drum motors. We have made allowance for this behaviour. The FTK Förderband Technik Kilian drum motors only require an oil change after 50,000 hours of work. In the case of operation with 3 shifts for example

Request for a quote

KROMA LTD

Serbia

Rotary pressure joint is an assembly which secures sealing between inlet pipe and rotational cylinder thus providing heat transfer by media in or from the equipment's rotational element. Fluids that are commonly used for heat transfer are water, thermal oils, hydraulic oils, cooling fluids and vapor. When it comes to rotary pressure joints, sealing of work fluids is done by the use of mechanical seal. The mechanical seals spring provides contact between sealing faces before the machine starts it's work, while during work, the contact is secured by the act of hydraulic pressure, except in cases of low operating pressures or vacuum. The right choice of mechanical seal is of major importance in order to reach the work of rotary pressure joint efficient , because in cases of mechanical seal malfunction, leakage occurs which reduces efficiency of entire cooling or warming process. “ Kroma Ltd” delivers rotary pressure joints with either single or dual flow.

Request for a quoteResults for

Rotating seals - Import exportNumber of results

12 ProductsCompany type