- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotating equipments

Results for

Rotating equipments - Import export

ROBINSON CO.

Turkey

The mixer is designed to homogenize the mixing of different raw materials milled to the mill with poor free flow during the process. Both types of mixing are possible with or without the addition of liquid. it provides a mixture of raw materials crushed with a precision of 1/100000. The loading time is reduced by pneumatic traps in a large area; and the unloading time is reduced by double unloading hatches that can be opened from end to end.The position/time increases with the time gained during the finishing process.There are 100% safe unloading housings that do not load Rotating equipment should never be opened unless the cycle is completed. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

FERPLAST SNC

Italy

To be installed at the exit of the packaging machines and welding machines. ROTATING TABLE OF ACCUMULATION WITH STAINLESS STEEL STRUCTURE AND NYLON PLAN The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The rotating tables with nylon plan are available with a diameter of 800, 1200 or 1400 mm, and are suitable for bottles, cans and products that can overturn in the concave or convex turntables. The flat rotating tables can be equipped with loading systems and automatic unloading and thus be used as "accumulation areas" between an automatic machine and another. Edges and sides nylon version Flat turntable with holding sides, polyethylene plan, useful height of 810 mm and a mechanical speed variator.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

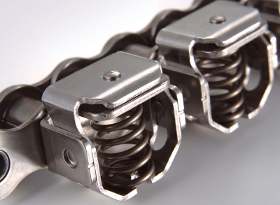

Our high-performance roller chains combine traditional and modern innovations, making them ideal for forming, filling and discharging processes. These chains are equipped with side-rotating gripper attachments, making them an excellent choice for vacuum seal applications. The designed gripper attachments offer a reliable clamping feature and have special mechanisms to ensure precise positioning. The high-performance springs used in our chain are specially designed to increase their durability and ensure long life in harsh conditions, up to 10 million cycles, even at high speeds. Additionally, the Type M design maximizes the attachment's ability to rotate laterally, keeping your lines running smoother and more efficiently. With these features, our product is an ideal option to make your transactions more reliable and effective

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Secondary Impact Crusher is a type of crushing machine that typically comes in the form of a Horizontal Shaft Impactor (HSI). This crusher is designed to provide secondary or tertiary crushing capabilities by generating high-speed impact forces to further reduce the size of the material processed. In comparison to a Primary Impact Crusher, a Secondary Impact Crusher is usually aimed at producing smaller, finer particles and more refined end products. It operates by utilizing a rotating rotor equipped with impact tools such as hammers or blow bars that strike the incoming material, causing it to break apart through impact forces. Secondary Impact Crushers are commonly used after primary crushers in various industries such as mining, quarrying, and recycling to achieve a more refined product size or shape. These crushers excel at producing well-shape aggregates, finely crushed materials, and secondary applications requiring fine particle sizes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Secondary Impact Crusher is a type of crushing machine that typically comes in the form of a Horizontal Shaft Impactor (HSI). This crusher is designed to provide secondary or tertiary crushing capabilities by generating high-speed impact forces to further reduce the size of the material processed. In comparison to a Primary Impact Crusher, a Secondary Impact Crusher is usually aimed at producing smaller, finer particles and more refined end products. It operates by utilizing a rotating rotor equipped with impact tools such as hammers or blow bars that strike the incoming material, causing it to break apart through impact forces. Secondary Impact Crushers are commonly used after primary crushers in various industries such as mining, quarrying, and recycling to achieve a more refined product size or shape. These crushers excel at producing well-shape aggregates, finely crushed materials, and secondary applications requiring fine particle sizes.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Our mobile field service teams provide any kind of service on electrical or mechanical equipment such as inspection, diagnostic measurements, maintenance and repairs of rotating equipment and transformers. In addition, our field crew can also perform minor- and major overhauls, including commissioning and start-up assistance. All of our field service activities can be performed on scheduled or non-scheduled basis. Maintenance Partners’ field teams are highly flexible and can cover a broad range of maintenance activities, for example: Complete stop based maintenance On site engineers to support your maintenance department Contract based maintenance Condition monitoring and diagnostic measurements Removal of rotating equipment for overhaul Installation of rotating equipment after overhaul On site bearing changes Laser alignment On site balancing of fans

Request for a quote

MAINTENANCE PARTNERS

Belgium

Field Service: Activities Our mobile field service teams provide any kind of service on electrical or mechanical equipment such as inspection, diagnostic measurements, maintenance and repairs of rotating equipment and transformers. In addition, our field crew can also perform minor- and major overhauls , including commissioning and start-up assistance . All of our field service activities can be performed on scheduled or non-scheduled basis. Maintenance Partners’ field teams are highly flexible and can cover a broad range of maintenance activities, for example: Complete stop based maintenance On site engineers to support your maintenance department Contract based maintenance Condition monitoring and diagnostic measurements Removal of rotating equipment for overhaul Installation of rotating equipment after overhaul On site bearing changes Laser alignment On site balancing of fans Equipment To provide a complete onsite service, our field teams have a broad range of equipment at...

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners offers training courses on various technical subjects to its customers. Trainings allow you to obtain in-depth knowledge about maintenance of mechanical and electrical rotating equipment. Depending on your specific needs and goals, trainings can also be customized to be more effective. Training Courses AC Motors Balancing Compressors DC Motors Gearboxes Generators Material Analysis Mechanical Measurements Pumps Rewinding Steam Turbines Vibration Measurement & Analysis

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners offers training courses on various technical subjects to its customers. Trainings allow you to obtain in-depth knowledge about maintenance of mechanical and electrical rotating equipment. Depending on your specific needs and goals, trainings can also be customized to be more effective. Training Courses AC Motors Balancing Compressors DC Motors Gearboxes Generators Material Analysis Mechanical Measurements Pumps Rewinding Steam Turbines Vibration Measurement & Analysis Contact Want to now more about the trainings above or how Maintenance Partners can provide a customized training for your personnel?

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners’ Marine & Offshore department covers field and workshop services for customers all over the world. The locations of our workshops allow for quick and flexible services to the ports of Antwerp, Ghent, Rotterdam, Zeebrugge and Le Havre. Member of ISES – The International Ship Engineering Service Association We are also a full member of the ISES Association (The International Ship Engineering Service Association). The ISES Association network consists of service companies located throughout the world, this further expands the available services that Maintenance Partners offers internationally to its customers in the marine and offshore industry. Electrical & Mechanical Equipment Services We offer maintenance and repair services on electrical and mechanical rotating equipment, such as: AC/DC Motors (incl. Explosion Proof & Submerged Motors) Diesel Engines Gearboxes Winches (mooring winches & hoisting winches) Magnetic Couplers for Motorized...

Request for a quote

MICROMEGA DYNAMICS S.A.

Belgium

Experiencing excessive vibrations in sensitive mechanical structures or rotating machinery? Tuned Mass Dampers (TMD) and Tuned Mass Absorbers (TMA) provide a simple and effective solution to reduce them. TMA and TMD are mechanical resonant devices used to suppress or absorb vibrations. When installed properly on a machine or structure, they draw away vibrational energy from the structure or machine and dissipate it internally, hence reducing their motion. They do not require a redesign of the target structure/machine and do not interfere with the main structure/machine function. This makes them an ideal solution for existing machine retrofitting/troubleshooting.Whenever alignment and balancing of the rotating equipment has been performed but the vibration level is still too high Excessive structural vibration excitation during ramp-up or slow-down (stirring machine, flywheel, etc.) MECHANICAL STRUCTURES

Request for a quote

MAINTENANCE PARTNERS

Belgium

When an initial inspection shows that a repair is not economically feasible, Maintenance Partners can offer you new equipment. This allows us to provide you with a complete solution, even when a replacement is required. We have agreements with various manufacturers and distributors of rotating equipment and can supply: Electric motors Mechanical seals Pumps Gearboxes Gemex Supply of new Electric Motors We supply new electric motors of any brand, such as WEG, ABB, Svend Høyer, Rotor, TECO and Ansaldo. This allows us to provide you with new electro motors in any segment and type. Certified Service Center for WEG Maintenance Partners has been certified as Service Center for WEG . This certification means that Maintenance Partners is an authorized repair workshop for: Induction Squirrel Cage HV Motors Synchronous Machines and Generators DC Motors Field Service This cooperation guarantees that repairs performed by MP meet WEG’s quality standards. Besides this, short lead times and...

Request for a quote

MAINTENANCE PARTNERS

Belgium

When an initial inspection shows that a repair is not economically feasible, Maintenance Partners can offer you new equipment. This allows us to provide you with a complete solution, even when a replacement is required. We have agreements with various manufacturers and distributors of rotating equipment and can supply: Electric motors Mechanical seals Pumps Gearboxes Gemex Supply of new Electric Motors We supply new electric motors of any brand, such as WEG, ABB, Svend Høyer, Rotor, TECO and Ansaldo. This allows us to provide you with new electro motors in any segment and type. Certified Service Center for WEG Maintenance Partners has been certified as Service Center for WEG . This certification means that Maintenance Partners is an authorized repair workshop for: Induction Squirrel Cage HV Motors Synchronous Machines and Generators DC Motors Field Service

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners’ Marine & Offshore department covers field and workshop services for customers all over the world. The locations of our workshops allow for quick and flexible services to the ports of Antwerp, Ghent, Rotterdam, Zeebrugge and Le Havre. Maintenance Partners Marine - Member of ISES - The International Ship Engineering Service AssociationMember of ISES – The International Ship Engineering Service Association We are also a full member of the ISES Association (The International Ship Engineering Service Association). The ISES Association network consists of service companies located throughout the world, this further expands the available services that Maintenance Partners offers internationally to its customers in the marine and offshore industry. Electrical & Mechanical Equipment Services We offer maintenance and repair services on electrical and mechanical rotating equipment, such as: AC/DC Motors (incl.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

The LUBExpert ON-GUARD, our smartest lubrication solution, blends automation with precision, reliability, simplicity, and safety. It ensures long-lasting, trouble-free operation of your rotating assets by maintaining optimal lubrication, all through innovative ultrasound measurement technology. Reliability through Condition-Based Lubrication As much as 80% of bearing failures are attributed to poor lubrication practices. The LUBExpert ON-GUARD eliminates the guesswork from this crucial maintenance task by ultrasonically monitoring the friction levels of rotating equipment, and applying lubrication precisely as needed. Rely on data-driven decisions with the LUBExpert ON-GUARD. Move beyond time-based calculations and embrace a maintenance strategy where precision and accuracy are paramount. This failureless approach acts as a nutritionist for your machines, preventing problems through a personalized, autonomous, and data-driven plan, thereby fortifying operations reliability.

Request for a quote

ACEMAL NV

Belgium

Conveyor belts Accessories Watch our production lines on video Armoires de fermentation We create fermentation chambers according to the needs of the customer. They are equipped with rotating shelves in stainless steel and are available in all sizes.

Request for a quote

COMERC SP. Z O.O.

Poland

Screw conveyorsare used for transporting sawdust, wood chips, pellets and other bulk materials. Conveyor housing is made of structural steel with Magnelis® coating. Wormwheel is made of thick-walled steel pipe with 10 mm thick spiral welded to the pipe. End necks welded on both ends of the wormwheel are designed to be mounted in high-quality self-aligning ball bearings (SKF or INA/FAG) with UCF housing. Additionally, our screw conveyors are equipped with rotation monitoring sensors and inspection hatches with overflow sensors.Depending on the requirements and purpose belt conveyors could work with capacities from 15 m3/h to 100 m3/h. Screw conveyors (also known as auger feeders) are used in various industries, and their design can be adapted to the specifics of each industry, if necessary. The screw feeders we manufacture are part of the pellet production lineswe design and build, and ensure stable, even feeding of the raw material to the next production stage.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Positioner is designed in order to change the piece’s position, tied onto it, to the best and weld. It gives movement opportunity on two independent lines which are rotating and angular positioning. Positioners can be fixed to the ground according to weight and center of gravity of the work piece. Flange rotating speed can be sensitively adjusted with the control. Optionally it can be adapted with Column-bom system as to work synchronized. Rotator and positioning motors are equipped with thermic protector separately.

Request for a quote

ABS SAFETY GMBH

Germany

Particularly robust self-retracting lifeline (SRL) with a steel cable - available in a range of maximum expandable lengths up to 30 m. Rope-up protection for 1 individual in combination with personal protection equipment (PPE). EN 360:2002 Strength rating: 12kN Upper and lower rotating brackets prevent twisting Carabiner equipped wtih a fall indicator

Request for a quote

ABS SAFETY GMBH

Germany

You can move freely all around this centrally-installed stainless steel anchorage point. It is equipped with a rotating anchorage eyelet - making it suitable for wall, ground, facade and overhead installation. The 80 mm thread (M16) is firmly cemented into concrete using special adhesive. National technical approval ("abZ"): Z-14.9-688 (max. 2 individuals) (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 (max. 3 individuals) EN 50308:2004 (max. 2 individuals) Freely rotating eyelet Concrete ≥ C20/25 Recommended accessories: Special Adhesive WIT-VM-250 Not suitable for recurrent abseiling usage when installed overhead!

Request for a quote

STARRAG GMBH

Germany

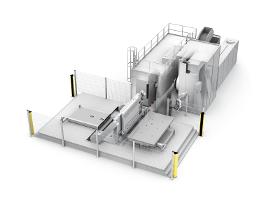

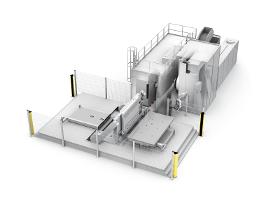

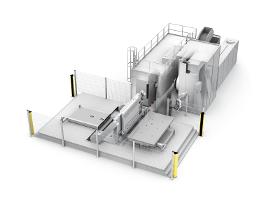

Scharmann has developed the ECOSPEED F for highspeed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED. What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the Xaxis, which enables component loading and unloading during the machining cycle.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Heat conductive ePTFE Yarn, PTFE fiber, Run-In Lubricant and elastic Silicon Tube Core Practical useful application data: max. temperature: +160 °C Characteristics Elevated heat conductivity For higher shaft speeds than S 6 SKV High chemical resistance and for clean media Operating range Pressure [p max]: 20 bar, Velocity [v max]: 10 m/s Temperature: t = -100… +280 °C pH: 1 - 14 Density: 1.60 g/cm³ Practical useful application data: max. temperature: +160 °C Main application Mixer Agitators Autoclave Kneader Paddle dryer Suitable for Rotating Equipment with higher surface speed radial run out Form of delivery This packing can be manufactured from 14 to 40 mm square as well as in intermediate, inch sizes and special measurements. 14 mm and above on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg of packing of the following cross-sections corresponds to displayed meter lengths: Size mm["] Meter 14 [9/16"] 3.2 15 2.8 16 [5/8"] 2.4 18 1.9 19 [3/4"]...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE-fiber with PTFE Impregnation, Run In lubricant and elastic Viton Tube Core Practical useful application data: max. temperature: +200 °C Characteristics Chemical resistance For clean products and static sealing application Operating range Pressure [p max]: 25 bar, Velocity [v max]: 6 m/s Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.55 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Mixer Agitators Autoclave Kneader Paddle dryer Suitable for Slow Rotating Equipment with radial run out Form of delivery This packing can be manufactured from 14 to 40 mm square as well as in intermediate, inch sizes and special measurements. 14 mm and above on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg of packing of the following cross-sections corresponds to displayed meter lengths: Size mm["] Meter 14 [9/16"] 3.3 15 2.9 16 [5/8"] 2.5 18 2.0 19 [3/4"] 1.8 20 1.6 22 [7/8"] 1.3 25 [1"] 1.0

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100% PTFE - Fiber with special PTFE Dispersion and FDA conform Siliconoil impregnated Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 25 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar, Velocity [v max]: 1 m/s Pressure [p max]: 500 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Pulp and paper industry Chemical industry Pharmaceutical industry Food industry Approvals FDA conformity EN 1935:2004 in accordance with EN 10/2011 Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 -...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE Fiber with PTFE Blocking Agent and Silicone Free Run-In Lubricant Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 15 bar, Velocity [v max]: 10 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 100 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Chemical industry General industry Variant S6SI with Food certification EG 1935:2004 in accordance with EU 10/2011 FDA conformity Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn with Meta-Aramid fiber reinforcement and Run-In lubricant Characteristics Clean packing with ultimate heat conductivity for abrasive products in pumps and other rotating equipment. Recommended shaft surface hardness: HRC 35 Porosity filling coating increases density and protects the packing in crystallizing mediums. W-Profile Reinforcement reduces shaft wear Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 13 Density: 1.55 g/cm³ Main application Centrifugal pumps Mixer Agitators Kneader Filter Suitable for Pulp and paper industry Chemical industry Power plant technology Waste water technology Applications with abrasive products and when white packing is required Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid-Braid in W-Profile made of ePTFE/Graphite and Graphite yarn with Run-In Lubricant Characteristics Universal packing for sealing abrasive mediums in all manner of plant rotating equipment Low Coefficient of friction and ultimate heat conductivity High plant standardization possibilities Recommended Shaft Surface Hardness HRC35 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 25 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.55 g/cm³ Main application Centrifugal pumps Mixers Kneaders Agitators Refiners Autoclave Filters Suitable for Bauxit Industry General Mining Ash Slurrries in Power plants Pulp and paper industry Chemical industry Waste water technology Universal use Form of delivery This packing can be manufactured from 6 to 40 mm square as well as in intermediate, inch sizes and special measurements. 06 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5...

Request for a quote

STARRAG GMBH

Germany

Scharmann has developed the ECOSPEED F for highspeed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED. What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the Xaxis, which enables component loading and unloading during the machining cycle

Request for a quote

STARRAG GMBH

Germany

Scharmann has developed the ECOSPEED F for highspeed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED. What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the Xaxis, which enables component loading and unloading during the machining cycle

Request for a quoteResults for

Rotating equipments - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (4)

- Offshore services (4)

- Broaching - steels and metals (1)

- Concrete preparing - machinery and equipment (1)

- Crushing and grinding machinery (1)

- Flour milling - machinery and equipment (1)

- Frequency and tuning devices (1)

- Greasing equipment (1)

- Industrial equipment hire (1)

- Joints, hydraulic (1)

- Lubrication equipment and machinery (1)

- Machine tools, cutting - parts and accessories (1)

- Monitoring and control equipment (1)

- Piston pumps (1)

- Pneumatic conveyor equipment (1)

- Steels and metals - welding and brazing (1)

- Turntables (1)