- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotating device

Results for

Rotating device - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

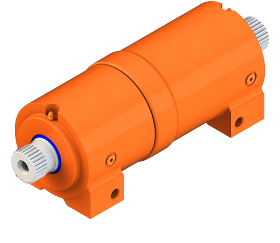

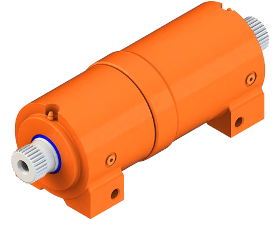

The T20 series with toothed output shafts and a rotation angle of 200-220 degrees is ideal for applications where torque generation and higher cycle rates are the most important requirements. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in three standard sizes with an output torque of up to 6,780 Nm at 210 bar.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Everywhere, where digital signals must be electrically separated and processed or current and voltage limited power supply is needed, our interface devices are used such as isolating switching amplifiers, solenoid drivers, relay couplers and rotation speed monitors. The interface devices are available in the IP20 modular housing for DIN rail as well as in the compact IP67 housing for decentralized remote-site use. The product portfolio also comprises solutions for the Ex area and SIL-certified devices.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Cylinder with double piston rod as anti-rotation device against linear movement of the piston rod. Design based on ISO standard. Available sizes diameter: 32, 40, 50, 63, 80, 100 mm.

Request for a quote

STATEC BINDER GMBH

Austria

The high-performance high-level palletizer PRINCIPAL-H is capable of palletizing up to 2400 bags or cartons per hour. The fast high-level palletizer is equipped with an empty pallet magazine and an outfeed system. A bag flattener at the beginning ensures that the bags are “in shape” for stacking. Flexible layer patterns are made possible by a servomotor-driven overhead rotating device that rotates the bags to the required position. For example, the bags can be positioned so that the bag seams point inwards or barcodes can be read from the outside. A well-structured layer pattern is guaranteed by the synchronous belt drive of the layer pusher, which enables the exact positioning of the bags or boxes, and the motor-driven front and side shifters, which ensure a stable and right-angled layer.

Request for a quote

FERPLAST SNC

Italy

The LARGE Spring balancers allows to effortlessly lift gluing machines, stapling machines, nailing machines, strapping machines and other tools with weight from 15,0 to 180 Kg The balancers are an essential tools to ease the operator work and increase productivity. They also reduce the processing time and help improve the quality of work. The balancers are manufactured according with the DIN 15112. The Large and Extra Large series balancers can be equipped with optional: - BA: control device from the bottom - RE: rotating device and isolation

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 32 x 43 cm age 2001 perfect binder Navigator control computer control with touch screen 5 clamps for hand feeding motoric size adjustment milling- and roughening station waste vacuum system Hotmelt spine glueing Hotmelt side glueing rotation cover feeder grooving device gauze station nipping station infeed belt max. 2.000 cycles / h (off-load) block thickness approx. 2 - 70 mm Ref: WO240152A Please ask for price. We ship and install worldwide!

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

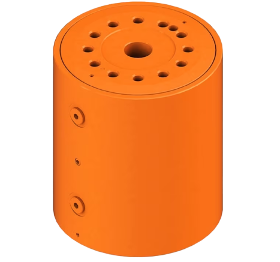

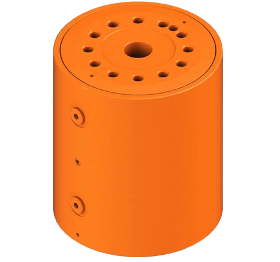

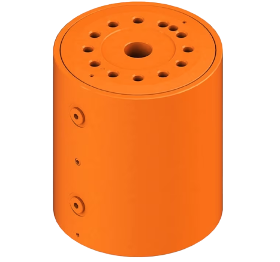

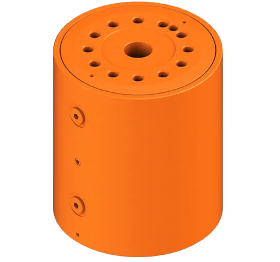

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

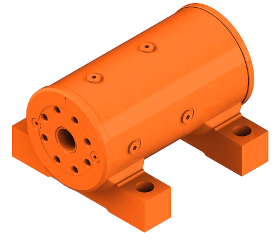

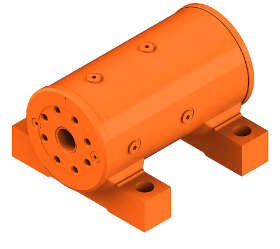

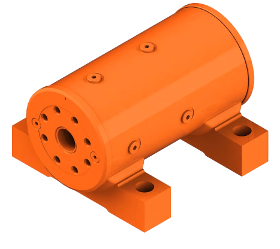

The L-20 series is a particularly cost-effective solution that is suitable for a wide range of applications. It has versatile mounting options and a flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 4,400 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-20 series is a particularly cost-effective solution that is suitable for a wide range of applications. It has versatile mounting options and a flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 4,400 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-20 series is a particularly cost-effective solution that is suitable for a wide range of applications. It has versatile mounting options and a flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 4,400 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The T20 series with toothed output shafts and a rotation angle of 200-220 degrees is ideal for applications where torque generation and higher cycle rates are the most important requirements. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in three standard sizes with an output torque of up to 6,780 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The T20 series with toothed output shafts and a rotation angle of 200-220 degrees is ideal for applications where torque generation and higher cycle rates are the most important requirements. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in three standard sizes with an output torque of up to 6,780 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The T20 series with toothed output shafts and a rotation angle of 200-220 degrees is ideal for applications where torque generation and higher cycle rates are the most important requirements. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in three standard sizes with an output torque of up to 6,780 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-30 series consists of our hydraulic drive with helical gearing for heavy-duty applications; it is particularly suitable for harsh environments. The L-30 series is designed for applications requiring extremely high load capacity and is available with a foot or flange mounting option with flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in ten standard sizes with an output torque of up to 83,600 Nm at 210 bar.

Request for a quote

AUROMAK MAKINA

Turkey

The multiprocess parts washing machine with rotating basket is a cleaning device for industrial use.This machine has been designed to ensure that parts are washed effectively and quickly. The main feature of the machine is the rotating basket system.The pieces are placed in a specially designed basket and the basket is washed by rotating it on a rotating mechanism. In this way, each surface of the parts is cleaned equally and a more effective washing process is performed. The Multiproces feature allows different cleaning stages to be performed on the same machine.For example,you can perform different operations such as detergent, spraying, brushing and rinsing on a single machine. Multiprocess parts washing machine with rotating basket is ideal for cleaning parts used in automotive, machinery, electronic equipment and similar industries. It optimizes the production process and increases quality by providing fast, effective and reliable cleaning.

Request for a quote

TASK ITALY SRL

Italy

The machine allows labeling with self-adhesive labels on large cylindrical or shaped bottles and drums, from the food sector to chemicals. It enables working with products of different shapes and sizes with a few simple adjustments. These machines are always tailored to the specifications of the product to be labeled, whether round or rectangular, with one or two label distribution groups. Optional features include non-standard size conveyor belts, pulling motorizations, fixed or rotating accumulation tables, handle centering devices, thermal transfer or ink-jet printing systems. Self-adhesive stations driven by stepper motors for maximum application precision, electronic board for label start signal, precision electronic adjustment of label positioning, motorized top conveyor for stabilizing square-rectangular containers. Production: from 2,000/h to 12,000/h.

Request for a quote

MAGTROL

Switzerland

DESCRIPTION The Torque Powder Brakes (TPBSeries) are ideal for applications operating in the low speed range or middle to-high torque range. These magnetic powder brakes provide full torque at zero speed and are convection or air cooled, allowing power ratings up to 900W (2100W with air cooling). APPLICATIONS These units are suited for tension control applications, such as wire winding, foil, film, and tape tension control. Mounted on test benches, TPB Series - Torque Powder Brakes allow performance and reliability testing on driving elements such as electric motors, hand-held power tools, geared motors, reduction gears, and hydraulic transmission systems. Other applications include load simulation for life testing on electric motors, actuators, gearboxes, power steering, and many other rotating devices and assemblies.

Request for a quote

ORBITEC GMBH

Germany

The RBK 60 S is an extremely robust water-cooled weld head for a standard heat exchanger application up to an ID of 60 mm, modified to an ID of 99 mm or 120 mm. The head is pneumatically centred and is available with a rotating wire device and/ or arc voltage control (AVC) as an option. The head can also be used with a pneumatic positioner instead of a balancer. Versions: — RBK 60 S weld head with pneumatic centring, including hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring and wire feeder incl. hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring, wire feeder and AVC incl. hose package, 8m, water-cooled Package includes: — Weld head — Small torch incl. torch consumables and tungsten electrode Ø 2.4 mm — Water-cooled hose package, 8 m — Pull bar B — Transport case Optional: — Div. spring sleeves and pull bar sets for RBK 60 S — Torches, Balancer, Tube-to-tubesheet positioner...

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Tailor-Made Trucks for Special Applications Depending on your requirements an individual glass transport system can be developed which will be tailor-made to exactly suit your needs. Please contact the HUBTEX specialists in Fulda/Germany. Electric Multidirectional Sideloader model MQ 30/MQ 60, load bearing capacity 3,000 kg / 6,000 kg with glass pack rotating device The HUBTEX Multidirectional Sideloader with glass pack rotating device allows you to rotate DLF glass packs from the horizontal to the vertical orientation and vice versa. Thus, individual wishes of your customers can be fulfilled. Additionally, MQ 30/MQ 60 can put unpacked glass packs directly in the prepared packaging box. This makes handling easier and saves time. Another advantage is that the glass packs can be stored edgewise in block storage. Thus, the storage capacity can be optimized.

Request for a quoteResults for

Rotating device - Import exportNumber of results

46 ProductsCompany type

Category

- Electric motors and parts (19)

- Industrial washing facilities (5)

- Bathroom accessories (2)

- Balancing machines and systems (1)

- Binding - machinery and equipment (1)

- Buckets and grabs, crane (1)

- Centrifugal pumps (1)

- Ceramic and enamel kilns (1)

- Construction cranes (1)

- Cylinders, pneumatic (1)

- Fasteners, metal (1)

- Finishing and binding - machinery and equipment (1)

- Labelling machines, office (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Monitoring and control equipment (1)

- Nuts (1)

- Oiling - machines and systems (1)

- Packing and packaging - machinery and equipment (1)

- Testing equipment (1)

- Tying machines (1)