- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotating cylinders

Results for

Rotating cylinders - Import export

CIC - KLAUS CZERWONKA

Germany

Cylinder with double piston rod as anti-rotation device against linear movement of the piston rod. Design based on ISO standard. Available sizes diameter: 32, 40, 50, 63, 80, 100 mm.

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

3570 PZ knob for half profile cylinder, rotatable and lockable, ø 40 mm, 2 grip moulds, metal nickel plated, for bore hole ø 24mm, 7 mm square, for door thickness 18-26 mm

Request for a quote

PROFIPACK S.R.O.

Czech Rep.

rotational stamping cliche, stamping sleeve, cylinder stamping die, brass material, vine labeling

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

During metal scrap processing, conveyance systems using augers or steel belts frequently fail to consistently move bushy bundles of metal scrap because the augers and steel belts are unable to grab hold of the stringy wads. This limitation causes the bundles to bounce around the in-feed hopper until an operator manually breaks them up, or forces the bundle up the conveyor. This practice is both inefficient and unsafe. The PRAB Bundle Breaker installs in a conveyor’s in-feed hopper, where dual rotating cylinders agitate the material, tearing stringy wads of chips, turnings, and bundles apart to allow for effective processing in downstream equipment. The PRAB Bundle Breaker may be added to an existing conveyor or incorporated into a new PRAB metal scrap processing system.

Request for a quote

AVM AUTOMATION

France

U guide unit for pneumatic cylinders ISO Ø12 to Ø80 Antirotation guide on bronze bearings Protected by wipers seals Antirotation for ISO pneumatic cylinder This Light Series provides antirotation of the cylinder rod. With limited dimensions, it permits to use an ISO cylinder for shortstroke translations, while protecting the rod of the cylinder with its floating rod coupling. For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and the front plate are remaining in anodized aluminum (suffix /AC after the reference). For all stainless steel guides, refer to the 34*X series.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

ENS HYDRAULIC NUT SPLITTER Our hydraulic nut splitter offers a reliable and effective solution to the removal of seized and corroded nuts. Triple edge replaceable cutting blade Blade positioning scale to eliminate bolt damage Cutting depth fixed - Nut size adjustable via rotating cylinder! Size range from 3/4" to 3-1/2" bolt diameters Designed to fit ANSI, ASME B.16.5 flanges Will work with some API flanges – contact factory for details Twin line hydraulic version available for subsea use Versatile, reliable and trouble-free operations Operates off a standard 10,000 psi (700 bar) pump unit Built-in safety relief valve to protect tool & operator Double acting (subsea) version comes standard with 700 bar, 1/4" NPT, Push to Connect (PTC) couplers. To use with top side pumps, change out couplers to 700 bar, 1/4" NPT, Screw-to-connect style.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

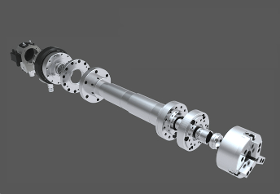

For example- Full System Chuck Adaptor Threaded Connector Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Part systems can be either: Front End- Chuck Adaptor Threaded Connector Drawtube Rear End: Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Or indeed any part(s) there of.

Request for a quote

GEYSER LLC

Russia

The СГИ 1200 cylinder head test stand is designed to detect micro cracks and air-tightness of the engine cylinder heads. The stand is equipped with a turntable for rotating the cylinder head in an aqueous solution and detecting tightness defects in different planes. This is a professional stand with pneumatic lifting and lowering of the turntable and electric 360-degree platform rotation drive. The cylinder head is sealed and placed in a heated aqueous solution. Thermal expansion of a heated part allows you to detect microcracks between valve seats, damaged plugs and other places in the cylinder head. Air is supplied through the opening in the cylinder head at a pressure of 4-6 bars. The presence of air bubbles allows you to detect a defective spot in the head.

Request for a quote

KROMA LTD

Serbia

Rotary pressure joint is an assembly which secures sealing between inlet pipe and rotational cylinder thus providing heat transfer by media in or from the equipment's rotational element. Fluids that are commonly used for heat transfer are water, thermal oils, hydraulic oils, cooling fluids and vapor. When it comes to rotary pressure joints, sealing of work fluids is done by the use of mechanical seal. The mechanical seals spring provides contact between sealing faces before the machine starts it's work, while during work, the contact is secured by the act of hydraulic pressure, except in cases of low operating pressures or vacuum. The right choice of mechanical seal is of major importance in order to reach the work of rotary pressure joint efficient , because in cases of mechanical seal malfunction, leakage occurs which reduces efficiency of entire cooling or warming process. “ Kroma Ltd” delivers rotary pressure joints with either single or dual flow.

Request for a quoteResults for

Rotating cylinders - Import exportNumber of results

13 ProductsCountries

Company type