- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling mill equipment

Results for

Rolling mill equipment - Import export

KEDY

Turkey

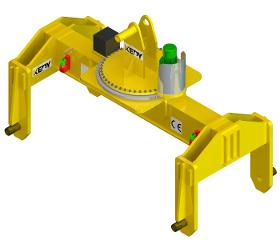

Introducing the KEDY K10100 Roll Mill Lifting Equipment, the perfect solution for your heavy-duty rolling mill operations. Designed with the latest technology and manufactured from high-strength materials, the K10100 is built to last and deliver outstanding performance. With its impressive load capacity, you can rest assured that your work roll will be safely and securely lifted and positioned every time. The K10100's size and shape are carefully crafted to fit your specific rolling mill design, ensuring a seamless integration into your operations. The surface finish of the K10100 is of the highest quality, providing durability and protection against corrosion and wear. Its connection points, such as hooks and lifting eyes, make it easy to attach and position your work roll, while its safety features, such as locking mechanisms and safety straps, ensure the safe and secure handling of your equipment.

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Chaoyang runxing heavy machinery Manufacturing Co.,ltd are engaging on manufacturing heavy machinery equipment and spare parts for almost 40 years, we could provide cement production line, rotary kiln, cement mill, ball mill, raw mill, slag mill, cement grinding equipment, preheating equipment, laterite nickel rotary kiln, oxidized pellet production line, air swept coal mill, mining mill, autogenous mill, semi-autogenous mill, rolling machine, vertical mill, crushing equipment, cooling machine, drying equipment, fluidized bed furnace, compound fertilizer equipment, blending machine, feeding machine. We passed the certification of ISO9000. Please contact us for more details. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

CERM-EX TECHNOLOGY INDUSTRY AND TRADING INC

Turkey

We have been providing a full range of steel fabrication services for our clients which includes Top International Contractors and Process Manufacturers. Our fabrication facility stands at 45,000 m2 of land area with welding lines, CNC Plasma/Gas cutting machines, MIG/MAG Welding, Cold Rolling machines, Milling equipment, shot blasting and sandblasting, painting and drying and corrosion protection machinery.With the help of our comprehensive machinery, experienced technical team and quality system our fabrication process becomes defect-free

Request for a quote

DOGA MAKINA

Turkey

We produce roll pairs and tube and pipe mills for the roll forming, tube, and pipe industries. we manufacture the tube mill rolls, For any tube mill line .Custom-made components for any product are included under specialized fabrication. Products are only fabricated using custom fabrication when certain specifications are fulfilled. The design, manufacture, measurement, and testing of products all include custom fabrication. used in mechanical, electrical, electronic, and other specialty manufacturing sectors. Customised manufacturing is another option for confirming that the products are of a greater quality and are more reliable.

Request for a quote

DOGA MAKINA

Turkey

We produce roll pairs and tube and pipe mills for the roll forming, tube, and pipe industries. we manufacture the tube mill rolls, For any tube mill line .Custom-made components for any product are included under specialized fabrication. Products are only fabricated using custom fabrication when certain specifications are fulfilled. The design, manufacture, measurement, and testing of products all include custom fabrication. used in mechanical, electrical, electronic, and other specialty manufacturing sectors. Customised manufacturing is another option for confirming that the products are of a greater quality and are more reliable.

Request for a quote

DOGA MAKINA

Turkey

Cold and hot drawing rolling mills, ring, roller, roller, disk or forming roller ring etc., called profile, wire, cable, electrode, iron, copper etc. The processing, manufacturing or, if desired, the correction of the rolling mills used in the drawing of materials such as profile, wire, cable, electrode, iron, copper etc. By performing highly precise cnc machining, both the quality of the product to be obtained is increased and the optimum benefit is provided to the customer by extending the life of the rolling mills used. By correcting the rolling mill tool, the customer's remanufacturing costs are reduced and the service life of the rolling mill tools is increased. Now these roller rings are processed and manufactured in the same quality in Turkey.

Request for a quote

DOGA MAKINA

Turkey

Forming profile group, manufacturing, repairing, correction, revision and rectifying work

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls. The bearings of the rolls are ductile iron and the arms of the rolls are conical. It is produced with gear drive and belt drive. It can also be produced with an optional touch control screen. Especially thanks to the side covers that can be opened one by one based on the opening system, it provides fast and easy access and the possibility of rapid ball removal with the cover opened on the ball.

Request for a quote

ROBINSON CO.

Turkey

The control sieve is used for the final control before packaging in the packaging unit of the flour factories. The product arriving at each passage of the square screen enters through the pressure pipe and moves vertically and horizontally through the pre-set flow paths along the passage. The final checks are made after the flour sifting process. The flour, whose last checks are made, is directed to the bagging process. Apart from flour and semolina factories, it is used in processing plants of wheat, corn and similar grains, in feed mills, in various food products processing plants for the final screening of mixed feeds and for the sifting of large-grain corn, crushed pellet feed, barley, oats and similar processes. Application Fields ◾ At flour mills: For wheat, corn and similar grain processing plants ◾ At feed mills: For final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processe

Request for a quote

ROBINSON CO.

Turkey

This machine is used in flour mills to separate the stuck core particles in the product coming from the roll. In this way, in flour production; Soft separation does not spoil the product. Both floor and ceiling hanging position shape, Right and left directions of spinner bars, Low power requirement, Coupling or pulley connection system Application Fields ◾ At flour mills ◾ At coarse and fine semolina passages ◾ After roller mills or before plansifter inlet

Request for a quote

ROBINSON CO.

Turkey

By separating the flour particles adhered to and remaining in the bran, it both prevents the loss of flour and increases the efficiency. Thanks to the special pallets on the rotor that rotates horizontally, the flour is separated from the bran while being thrown towards the screen. The centrifugal directed product strikes the pore size preselected screen. Thus, it is ensured that the flour particles are directed to the outside of the sieve and the bran to the outlet channel from the inside. Applications Fields ◾ Flour Mills ◾ Semolina Mills

Request for a quote

ROBINSON CO.

Turkey

This machine provides the sorting of crushed corn with speed adjustment. It makes density and size classification with vibramotor from sheets of different sizes. It separates the sticky products (bran, flour, corn...) that can be obtained from corn with the help of vacuum.

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls.

Request for a quote

ROBINSON CO.

Turkey

Low pressure aspirators are used in industrial establishments operating in the food sector, heating and ventilation facilities and in the casting industry. Aspirators, whose models are determined according to flow and pressure values, are used at different engine powers. It helps to classify products with air, especially in the cleaning and processing of grains in the food industry. Body and fan are manufactured with great precision and mounted on a strong steel base. Equipped with special blades and design, the fan can be easily installed and disassembled for high rotation needs. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. FEATURES - MFDJ It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. - MFNM - Best machine in practice. - Most economic spare parts. - Long life. - Seperation of fat with intensive operation. - Nindamac helps to achive high aqualit diffrent granulation of finished product with low fat content. For high technology degermination done by Nindamac by the

Request for a quote

ROBINSON CO.

Turkey

Bucket elevators are used to transport granular or powdered products with buckets attached to their belts from the bottom up. They are manufactured in various sizes and capacities according to the needs. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

This machine is utilised for blending of various sort of grain as asked for rates and conformity of limit before processing area or treating segment. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROBINSON CO.

Turkey

Molasses Mixer designed for homogeneous mixing of liquid sweetener to product additives in feed mill plants. U type body in Carbon Steel ST37 metarial up to requirement. Liquid with 1-11 % is mixed homogeneously. Maximum mixing is provided by heating molasses 40 - 42 degress. Applications Fields Food Business Industries Flour Mills Semolina Mills Seed Cleaning Facilities Malt Factories Feed Mills Corn Mills Grain Storage Silos

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

Instantly measure and display of humidity and hectoliter of wheat Calculation of water flows according to the required humidity. Automatic water dosage according to the calculated water flow value Automatic water dosage according to the wheat flow variation by the connection of wheat flow control or measure unit Alarms of failure More than one humidity – hectoliter measuring unit and water the dosage unit can be controlled by the PLC control unit.

Request for a quote

ROBINSON CO.

Turkey

Flowing the dry cleaning of wheat, it is used for the humidity of wheat with a little consumption of water and time. At the same time, the wheat is unshelled also because of the two rotor, which turns with high speed.It can add up to 7% of water in a single flow-through.

Request for a quote

ROBINSON CO.

Turkey

While the grain is carried upwards with the anchors made of hard material resistant to abrasion formed in appropriate dimensions on the rotor in an angled semi-cylindrical body made of stainless steel, the water is absorbed by the grain by subjecting it to intensive mixing at a measured speed. It is used in grain processing plants to ensure that the desired moisture content of the grains penetrate and feed the grain sufficiently. It brings the grain to be annealed with water and provides a homogeneous mixture. At the same time, a significant amount of peeling is ensured in the grain shell as a result of friction caused by the rotor rotating at high speed. Application Fields ◾ At food industry ◾ At the dry cleaning units of the flour and semolina mills ◾ At the grain processing plants where moistening process is required

Request for a quote

ROBINSON CO.

Turkey

It is used for separating garbage, straw, ear, other coarse and small foreign matter from wheat and other whole grains. In the food industry; In flour and semolina factories, seed cleaning facilities, grain cleaning and calibration facilities, grain factories, feed mills, silo facilities. In other similar industrial facilities; Low power consumption, high efficiency and high capacity Easy and minimum maintenance, trouble-free operation thanks to vibro-motor drive, Possibility to reach maximum capacity and efficiency for various grains with adjustable sieve angle, Durability and longevity Quick and easy replacement of sieves, practical cleaning possibility Quiet working

Request for a quote

ROBINSON CO.

Turkey

Thanks to the belt-pulley mechanism driven by an electric motor, the rotational motion is transferred to the sieve shaft. The sieve weights, which are placed unbalanced, connected to the sieve shaft, make the sieve vibrate. The position of the screen weights can be adjusted around the screen shaft in order to change the vibration amplitude of the screen. The screen is hung on the ceiling of the place where it is located by means of composite rods in order to create the vibration comfortably. Thanks to this vibration movement, in specially designed sieve boxes, the incoming product is classified and sifted according to its grain size. The product to be screened is sent to the screening area through one or more inlet pipes. Various types of silk-covered cases allow separation in seven channels. This part is directed to the outlet by the channel. After the product is sifted, it is sent to the outlet pipe on the bottom plate. It also has sight pipes for product control and monitoring.

Request for a quote

ROBINSON CO.

Turkey

It performs the dissolving and grinding process in the appropriate semolina passages of flour diagrams, in this passage it increases the flour yield at high rates. This process is carried out with lower energy than other grinders. These machines are used in coarse and fine semolina passages, It can be mounted right after the rolls or on the upper turning points of the pneumatic carrier pipes to be used as elbows. Application Fields ◾ Flour Mills ◾ Semolina Mills

Request for a quote

ROBINSON CO.

Turkey

It is used for cleaning and classifying semolina in flour and semolina factories. The product, whose flow rate can be adjusted, is evenly distributed over the entire screen surface by means of a curtain. Screening process is carried out with 2 or 3 layers of telero. With the aerodynamic air channel and adjustment valves, an equal vacuum is created on the whole screen surface, the products with extended adhesion surface such as bran and bran are separated from the product by vacuuming and pushed into the outlet channel. The product (semolina) free from bran is classified according to its grain size by means of sieves. Application Field ◾ At food industry ◾ Flour mills ◾ Semolina mills

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The hammer mill is used to shred / crush the products in smaller pieces by the repeated blows of little hammers.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

In flour mills, the roller mill is used to break and crush the wheat. This is the most important machine of a flour mill. It consists of two pairs of parallel working rolls. The product that collects into the inlet glass moves the pneumatic pressure plates and the feed rolls start to feed the products homogeneously into the rolls. In the meantime, the gap between the rolls is reduced by pneumatic pistons and the product is ground by passing between the rolls. The bushings of the roller mills are spheroid casting and the rolls have conical arms.

Request for a quoteResults for

Rolling mill equipment - Import exportNumber of results

46 ProductsCompany type

Category

- Flour milling - machinery and equipment (30)

- Flour-milling (24)

- Rolling mills - machinery and installations (10)

- Rolling mills - ferrous metals (2)

- Food Processing (1)

- Lifting equipment (1)

- Metal structural work (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Mining and quarrying - machinery and equipment (1)

- Wheels, castors and rollers - metal (1)