- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller manufacture

Results for

Roller manufacture - Import export

DOGA MAKINA

Turkey

Cold and hot drawing rolling mills, ring, roller, roller, disk or forming roller ring etc., called profile, wire, cable, electrode, iron, copper etc. The processing, manufacturing or, if desired, the correction of the rolling mills used in the drawing of materials such as profile, wire, cable, electrode, iron, copper etc. By performing highly precise cnc machining, both the quality of the product to be obtained is increased and the optimum benefit is provided to the customer by extending the life of the rolling mills used. By correcting the rolling mill tool, the customer's remanufacturing costs are reduced and the service life of the rolling mill tools is increased. Now these roller rings are processed and manufactured in the same quality in Turkey.

Request for a quote

COPIER MACHINERY

Netherlands

Copier Machinery manufactures roller benches up to 12-meter length, specifically for pipe roll grooving applications. Steel ball transfer units are placed on the bench allow a pipe to move and turn to support the roll grooving application perfectly. Grooving roller benches are electrically height-adjustable and scalable upon special requirements.

Request for a quote

COPIER MACHINERY

Netherlands

Pipe beveling and cutting is way faster end efficient with electrically height-adjustable roller benches. Our TRB roller benches are highly stable and have two control options manual and automatic for very heavy pipes or automated pipe operations. TRB roller benches are easy to adjust for different diameter and reduces the production time. Also, automatic TRB can be integrated into a fully automated production line. Copier Machinery also designs roller benches with measurement and pipe push up system, especially for pipe cutting. Suitable for pipe diameters up to outside diameter 56”, with a length option up to 12 meters. All TRB roller benches are designed and manufactured by Copier Machinery, and they are scalable upon special requests and requirements.

Request for a quote

EC PLAZA

South Korea

We.Dae Yang Rollent Co.,have established a great reputation as a leading conveyor roller manufacturer since 1990. We have been doing our best to supply the best-quality products with high-end technologies we have in order to live up to our customers' high expectations. Many patents, awards we have received only represent a minor part of our achievements. We have been supplying our best-quality products to a variety of companies leading their industries, such as mining, construction, cements, thermal power plants, conveyor system, factory automation..etc. all over the world. The credibility we have built represents the history and the future of our company. From now on, we, DaeYang Rollent Co., Ltd., will step up our efforts to reach the goal of becoming a world-class leading company.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-tai has the comprehensive processing capacity rolling, welding, NDT, leak test, heat treating sandblasting, painting, lathing, milling, boring, grinding, wire cutting, drilling, assembling. Hongfeng has 70 sets of various types of machining include 12 units of CNC boring & milling machine 5 units of CNC lathe. Advanced and perfect testing method provide good protection for quality control. Huan-tai also has long-term cooperation of many kinds of outsource supplier, such as forging, casting, and plating. So Hongfeng has enough capacity to achieve in different industry .

Request for a quote

WMC SINTERSTAR AG

Switzerland

Diamond profile rollers Individually manufactured Highest precision Hand-set sintered diamond profile wheels Mechanically set sintered diamond profile rolls Reverse electrolytically coated diamond profile rolls

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Due to the ever-increasing level of automation, coated rolls and rollers are now used in almost all production facilities. These rollers and rolls are used in a wide variety of applications (transport, finishing, cleaning, coating, drying, etc.). What is particularly important is the quality of the coating, which determines the service life of the roller and the processing process.We manufacture completely coated rollers, i.e. We provide you with the roller core made of aluminum, steel, etc. and the desired coatings (rubber, Vulkollan®, etc.) from a single source. We can also roughly pre-grind your rollers, finely grind them or even provide them with grooves.As a cost-effective alternative, we also offer you to have your rollers recoated by us. Here too we can choose between different coatings (rubber, Vulkollan®, etc.). According to the customer’s wishes, we can also pre-grind, finely grind or provide these rollers with grooves. We would be pleased to advise you!

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

If you have existing INDUSTRIAL, AGRICULTURAL or FOOD PRODUCTION BRUSHES that are worn and no longer able to operate at their best, why not have them refurbished or repaired rather than buy new brushes – it will save you money & the planet’s resources. Our repair & refurbishment service includes: • Stripping & re-tufting original brush bodies • Resurfacing or trimming worn filament tips • Advancements to durability & performance • Colour choices to compliment designated usage • Stripping and re-winding roller brushes • Manufacture new parts for obsolete machinery • Advice on new materials to make the brush more durable • Advice on filaments & materials for alternative applications

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

If you have existing INDUSTRIAL, AGRICULTURAL or FOOD PRODUCTION BRUSHES that are worn and no longer able to operate at their best, why not have them refurbished or repaired rather than buy new brushes – it will save you money & the planet’s resources. Our repair & refurbishment service includes: • Stripping & re-tufting original brush bodies • Resurfacing or trimming worn filament tips • Advancements to durability & performance • Colour choices to compliment designated usage • Stripping and re-winding roller brushes • Manufacture new parts for obsolete machinery • Advice on new materials to make the brush more durable • Advice on filaments & materials for alternative applications If you are unsure whether your brushes can be refurbished,call us on 44 (0)121 559 3862 for an assessment and we will inform you if your brush is able to be refurbished &/or repaired. If repairs are required we will advise on what can best be accomplished without you having to return to the OEM

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Roller Brushes are usually constructed by either winding strip brush around a mandrel or punching filaments into a body. Both methods have idiosyncrasies that are suitable for particular uses. If you are unsure which may be the best for your application, call us for advice, we have over 75 years experience of knowing which brush will be best for your requirement. Wound Brush Strip Roller Brushes are manufactured in a variety of configurations and densities, dependent on their application. We are able to design and manufacture most Wound Brush Strip Roller brushes to any required diameter, length or pitch, wound right hand or left hand or formed into a chevron.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

If you have existing INDUSTRIAL, AGRICULTURAL or FOOD PRODUCTION BRUSHES that are worn and no longer able to operate at their best, why not have them refurbished or repaired rather than buy new brushes – it will save you money & the planet’s resources. Our repair & refurbishment service includes: • Stripping & re-tufting original brush bodies • Resurfacing or trimming worn filament tips • Advancements to durability & performance • Colour choices to compliment designated usage • Stripping and re-winding roller brushes • Manufacture new parts for obsolete machinery • Advice on new materials to make the brush more durable • Advice on filaments & materials for alternative applications If you are unsure whether your brushes can be refurbished, call us on 44 (0)121 559 3862

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

Portable automatic X-ray Film Processor with daylight option for X-ray film processing of the highest level. Most important features Integrated Dryer: Perfectly developed films after careful drying Fully Automatic: Processor controlled developing and intuitive operation Precise Mechanisms: With precise manufactured roller packages any film development is successful at first attempt Optimal Results due to proven precision technology Professional film development is a complex process that is dependent on precise adherence to specific parameters. Because of the exact process control of the XR 24 NDT, optimal film processing results are assured. The special submersion-tank mechanics reliably prevents crystallization of the chemistry during the stand-by phase. * Spectacular results * Finest Details * Proper Developing

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Rollers with PVC resin polyamide PA or steel ACC pinion driven by tangential chain or chain links in series.The diagrams and tables on pages 54 and 55 show the dimensional characteristics and the minimum and maximum lengths of manufacture. The rollers are produced in the following versions: with pinion integral to the jacket for continuous transport; with friction pinion for stockpiling transport and in the connection of machines operating at different speeds.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

PVC-STEEL cylindrical and tapered rollers with one or two grooves rolled on the steel tube, driven by round belt links in series or individually connected to a transmission bar activated by the motor unit. PVC and PVC-STEEL rollers with flat or toothed polyamide resin PA or steel ACC pulley driven by tangential belt or belt links in series. The diagrams and tables on page 86 show the dimensional characteristics and minimum and maximum lengths of manufacture. The rollers for flat or toothed belts are produced in the following versions: with pinion integral to the jacket for continuous transport; with friction pulley for stockpiling transport and in the connection of machines operating at different speeds.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Rollers PVC-STEEL rollers with resin polyamide PA or steel ACC pinion driven by tangential chain or chain with links in serie. The diagrams and tables on pages 66 and 67 show the dimensional characteristics and minimum and maximum lengths of manufacture. The rollers are produced in the following versions: with pinion integral to the jacket for continuous transport; with pinion clutch for stockpiling transport and in connection of machines operating at different speeds.

Request for a quote

KRAUS BETRIEBSAUSSTATTUNG UND FÖRDERTECHNIK GMBH

Austria

Gravity rollers are manufactured in many different versions for a wide range of applications. They can be used both in gravity-operated conveyor systems and in systems with a manual drive.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

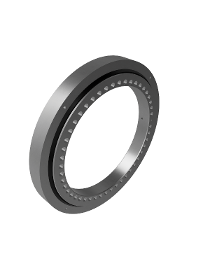

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quote

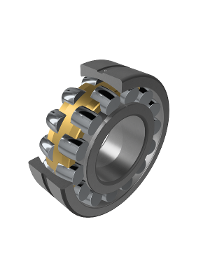

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

SELF TRUST - THE ROMANIAN CONVEYOR FACTORY

Romania

CITCOnveyors, division of SELF TRUST Romania, offer a wide range of gravity and powered roller conveyors, to suit customer individual requirements. The modular design allows for cost-effective integration of units to create highly efficient and adaptable handling systems. Other benefits: modular allowing flexibility and future expansion, wide range of auxiliary interfaces available, cost-effective, high quality, robust, low maintenance CITCOnveyors offers: Powered Conveyors, Gravity Conveyors, PVC Rollers Conveyors, Horizontal Conveyor, Inclined Conveyor, Curved Roller Conveyor, Pallet Roller Conveyor and more. For more types of conveyors please contact us!

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

TRAPOROL’s special polydirectional roller rails can be used wherever flat conveyed items have to be turned, sorted and shifted in different directions. Note: A and B edges should be mounted alternately next to each other; thus the rollers are arranged shifted in order to realize convenient roller distances. Series ARL 40, fits for ARS 40 Series ARL 48, fits for ARS 48 Series ARL 60, fits for ARS 60 Series ARL 80, fits for ARS 80 Series ARL 120, fits for ARS 120 Versions: — galvanized (untreated cut edges) — stainless steel — powder coated (RAL standard colors) — Special dimensions on request — on request, we manufacture complete tables, roller conveyor

Request for a quote

ALWAYSE ENGINEERING LIMITED

United Kingdom

With low capital costs and virtually maintenance free, Gravity Rollers offer a cost effective alternative for hundreds of applications including the movement of materials, goods or packages. Rollers can be manufactured to your own specification, please contact our experts to discuss your individual requirements.

Request for a quote

GURTEC GMBH

Germany

With over 12million units sold globally, the GUP Series is our most popular roller offering the best value for money in light and medium bulk materials handling. We’ve been manufacturing GUP rollers since 1980, using a fully automated production line that guarantees GURTEC’s German engineering quality in every roller, with the shortest lead times in the market.

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

This industrial steel roller is manufactured by us, OGGO Tech excels at producing rollersin Turkey, others include steel rollers for packaging, steel, food, beverages, conveyor systems, mining etc rollers. Turkey roller manufacturing and We carry out our roller manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our rollers sets. The selected applications in tool and roller production are determined by the part, manufacturing time periods, and eventually their dimensions. Roller manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quote

HERBERT PARKINSON LTD

United Kingdom

Herbert Parkinson Made to Measure roller blinds are produced using high quality components and are offered in a wide range of options. The standard roller blind can be supplied with either side chain control or spring return. Other system options include plain or covered cassette, perfect fit for double glazed units, Velux compatible and bottom up. Choose from an extensive range of speciality roller blind fabric, from sheers to blackout, or we can laminate your choice of fabric from our selection (printed, woven, plain or lightstop lining). Roller blinds may be ordered up to a maximum of 300cm width by 300cm drop, subject to weight and style restrictions. The standard finish is a fabric covered bottom bar, but other options include coloured aluminium bars, shaped finishes, poles, braids and embellished trimmings. ** Click for more **

Request for a quoteResults for

Roller manufacture - Import exportNumber of results

30 ProductsCountries

Category

- Bearings, roller (7)

- Conveyor systems (3)

- Metal brushes (3)

- Bearings - ball, needle and roller (2)

- Paint brushes and rollers (2)

- Rolling machines (2)

- Rolling mills - machinery and installations (2)

- Canvas for blinds and covers (1)

- Cold rolled sections (1)

- Diamond tools (1)

- Goods handling systems, continuous (1)

- Machine tools - metal machining (1)

- Pneumatic conveyor equipment (1)

- Radiology - films and accessories (1)

- Stainless steels (1)

- Wheels, castors and rollers (1)