- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rockwool

Results for

Rockwool - Import export

AKSA ACOUSTIC SOUND INSULATION MATERIALS

Turkey

Rockwool Suspended Ceiling Panel provides energy saving by optimizing the lighting and spreading the daylight to the place. Stone wool suspended ceiling panels; consists of a mixture of various chemical substances and recycled garbage, ground and pulverized into basal stone. Manufacturing is achieved by pouring and pressing the molten metal at a temperature of 3000 ° C in a molten state by mixing 54% of the basal stone with 36% chemical mixtures and 10% recycled garbage materials. Rockwool acoustic suspended ceiling panel 70% 95% 100% resistant to nursing. Absorbs noise and sound to clarify the sound in the environment. Demountable. It is fire resistant and can be painted if necessary. The pan will facilitate later renovations. Hygienic, suitable for human health, asbestosfree values and technical transactions are valid for all our panels. The international TÜV certificate, ISO 9001 and ISO 9002 certified, is manufactured to world standards.

Request for a quote

TEKNOFOAM AKUSTIK IZOLASYON SANAYI VE TICARET LIMITED SIRKETI

Turkey

Rockwool suspended ceiling systems are a ceiling covering option generally used in modern buildings. These systems are used on the ceilings of offices, schools, hospitals and other commercial buildings. Rockwool suspended ceiling panels are among the popular ceiling covering options of modern buildings due to their advantages such as acoustic performance, aesthetic appearance and environmental friendliness.

Request for a quote

YALÇIN BORU GEOTHERMAL

Turkey

The maximum temperature strength of standard type pre-insulated pipes is 140 °C. For this reason, rock wool reinforced (industrial type) pre-insulated seamless steel pipes must be used in lines that are required to operate at higher temperatures such as hot water, hot oil and steam lines.

Request for a quote

PANEL SELL GMBH

Germany

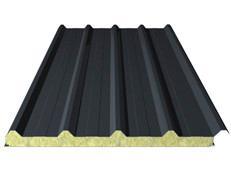

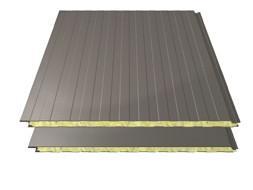

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

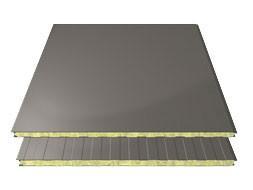

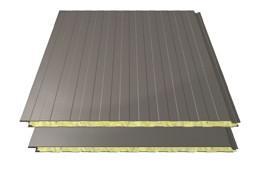

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

CBG COMPOSITES GMBH

Germany

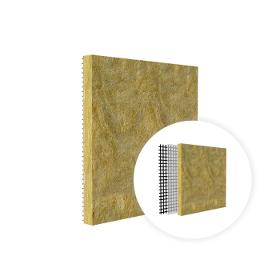

Multilayer refractory construction core based on rock wool and inorganic impregnation matrix for the production of fire-resistant building structures. ✓ 100% natural and inert ✓ non-flammable, according to IMO 2010 FTP Code Part 1, DIN EN 13501 ✓ meets the requirements of the RAL quality mark certification ✓ heat- and sound-insulating ✓ pressure resistant ✓ water-repellent ✓ dimensionally stable with temperature changes ✓ recyclable

Request for a quote

CBG COMPOSITES GMBH

Germany

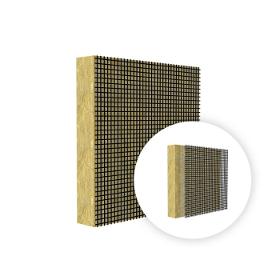

Component for production of composite and sandwich panels in shipbuilding and industrial construction. The rock wool panel as a base material is connected with a basalt fibre grid laminate by means of the inorganic flame retardant adhesive "LR Cerammatrix 01-50" with endothermic effect. Coatings with various surface materials, such as CPL, HPL or galvanized sheet metal are possible. A special feature of this panel is its excellent sound insulation properties. - 100% natural origin, chemically neutral — antibacterial — corrosion-resistant — thermoresistant — formstable — water repellent — vibration damping — non-combustible — no smouldering — recyclable

Request for a quote

CBG COMPOSITES GMBH

Germany

Component for production of composite and sandwich panels in shipbuilding and industrial construction. The rock wool panel as a base material is connected with a basalt fibre grid laminate by means of the inorganic flame retardant adhesive "LR Cerammatrix 01-50" with endothermic effect. Coatings with various surface materials, such as CPL, HPL or galvanized sheet metal are possible. A special feature of this panel is its excellent sound insulation properties. - 100% natural origin, chemically neutral — antibacterial — corrosion-resistant — thermoresistant — formstable — water repellent — vibration damping — non-combustible — no smouldering — recyclable

Request for a quoteResults for

Rockwool - Import exportNumber of results

13 ProductsCountries

Company type