- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robotic solutions

Results for

Robotic solutions - Import export

INAC

Spain

3D design software to create wooden pallets (INAC PALET CREATOR) Wood preparation machine (1 or 2 preparation tables) Smart Robot Nailing System Palletisation on chain conveyors Production control system

Request for a quote

INAC

Spain

Robotic system-based applications are one of the key Industry 4.0 innovations.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

There is now a reliable, low-cost range of robots available on the market. Produced in large numbers by reputable manufacturers, these robots can perform simple, repetitive tasks consistently and efficiently. They can easily be integrated into a production process, offering simple and flexible operation. Following an in-depth analysis, in collaboration with robot manufacturers and according to the technical constraints specific to your project, we provide the simplest robotic solution that offers the best compromise between technical compliance and overall financial cost.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. Industrial robots are the optimal solution for complex movements or systems with highest flexibility. We integrate and program the appropriate robot such as the Kuka robot and other brands.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

robot collecting cups filling solutions for high and fast production needs. Full Automatic Robot Collecting cups then arrangmrnt in special dish suitable for high capacity factories up to 25,000 cups/H

Request for a quote

HOCHRAINER GMBH

Germany

Fully automatic assembly system for complete assembly of joints Automatic change-over between part types is handled by robotic solutions.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

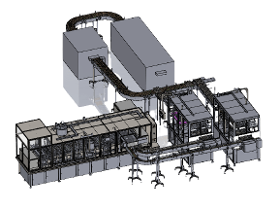

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

BizLink has completely redesigned the LSH guided robot dresspack solution to be more reliable, compact and flexible, thus making the LSH 3 the most innovative dresspack solution in the global market today. Its intelligent and extremely compact design minimise one of the most common causes of error for robot power supply – collision with interfering contours. This benefit in combination with extremely durable materials and proven components creates maximum clearance with a close-fitting dresspack on the robot arm.

ASP GERMANY

Germany

Paint stripping by high-pressure water blasting is very aggressive: splash back from jets, paint flakes, etc. For this reason, ASP has developed some original and effective solutions to keep your robot clean and to preserve its condition. Made from coated fabric, ASP’s covers are always the ideal solution for your robot protection problems. They are well-suited to painting processes (silicone free).

Request for a quote

ASP GERMANY

Germany

Paint stripping by high-pressure water blasting is very aggressive: splash back from jets, paint flakes, etc. For this reason, ASP has developed some original and effective solutions to keep your robot clean and to preserve its condition. Made from coated fabric, ASP’s covers are always the ideal solution for your robot protection problems. They are well-suited to painting processes (silicone free).

Request for a quote

ROBOTNIK

Spain

The RB-ROBOUT mobile robot is the solution for transporting heavy loads up to 1 tonne in weight, in indoor industrial environments such as factories or warehouses. Its ergonomic, low height and compact mouse-like design makes the RB-ROBOUT the ideal mobile robot for transporting both material trolleys and loads directly on the platform. It has a robust steel design and the dolly has omnidirectional kinematics based on 4 high power drive wheels. Thanks to the safety lasers, the RB-ROBOUT is an autonomous and collaborative robot able to share the working space with the operators in an intelligent way by detecting obstacles, searching for alternative routes and optimising trajectories. The robot is capable of operating with different types of localization: SLAM (map-based navigation) or philoguided (for very high precision requirements), and is able to use different modes in the same installation. All Robotnik robots are modular and their architecture is based on ROS.

Request for a quote

GIZELIS ROBOTICS

Greece

Gizelis Robotics provides turn-key solutions for machining with robots for all kind of materials like wood, stone, marble, alumium, steel etc. The robot cell consists of: Robot Spindle Robot CNC CAM Software Machining table Automatic tool change Safety fence There is also the possibility for costumers to bring their parts and make them a live demo. Robot CNC CAM software lets you program robots with external axes such as rotary tables and linear tracks as easily as you could program a 5-axis NC machine. Working closely with the highly skilled integrator Gizelis Robotics opened up new opportunities for testing the software which guarantees fast, accurate and easy multi-axis programming for robots.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

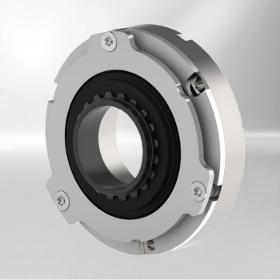

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

VELTRU AG

Switzerland

Reliability of automation solutions in their daily operation is a key criterion for their efficiency. Therefore, the layout and realization of the system are of major importance. By choosing a VELTRU robot system, you have laid the essential foundation. But a robot system is only as good as the technicians and engineers who have conceived the system and install the actual plant. Inadequately qualified staff members cannot comprehensively exploit the efficiency of robot solutions. As a consequence, the automation system will not be used in an optimal way. This results in process bottlenecks and the productivity of the system stays behind expectations. At VELTRU we consider training as a key to success. We know that our customers need qualified technicians in order to be able to fulfill end-user expectations in an automation job. This qualification can only be attained through professional training. Therefore, our educational support is directed particularly on the requirements of ent

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

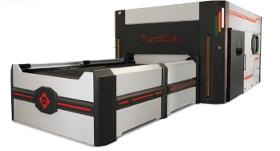

3000x1500mm / 4000x2000mm / 6000x2000mm Standard size Cutting Bed Fiber & Disk Laser Option Laser Power Range between 1kW-12kW Autofocus – Manual Focus Cutting Head Options Ramping Shuttle Table Advanded TurcCut New Generation HMI Metalix CAD/CAM Nesting Edge Detection Sensor Robotic Unloading Option Patented Back Reflection Sensor AVAILABLE FEATURES Robotic Integration Auto – Feeder Solutions Gantry System Unloading Laser Marking Unit Custom Size Cutting Bed Monitoring Camera Integration Existing Production Line I/O Connection (Ethernet)

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing offers a range of welding solutions including MIG welding, TIG welding, robotic welding, projection welding and spot welding for aluminium, mild steel and stainless steels. Our highly trained weld team are some of the best in the industry and our quality is second to none. Robotic Welding Alpha Manufacturing's installation of a robotic welding has increased our capacity to offer high accuracy weld detail in volume as well as 100% product repeatability. Robotic Welding is the perfect solution for customers who require high volume, highly accurate, repeatable products. Alpha's robot welder boasts high-end features such as Cold Metal Transfer technology to eradicate spatter and reduce burn-through and distortion. The Robot also comes equipped with Seam Finding technology to ensure the robot always welds true to joining parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JSC IC SPA ANDROID TECHNICS

Russia

Research and development work (R&D) is aimed at creating a new product or technology on the Customer’s specification. We perform: - Complex survey, research and development work in the field of robotics and mechatronics; - Development, design of complex robotic solutions with a guaranteed result: creating an experimental / mock-up / pre-production sample with the parameters specified in the technical specifications with a full package of design and software documentation. Effects of cooperation: 1. Guaranteed completed R&D program; 2. Saving money on R&D up to 40% and reducing the R&D performance period up to 2 times, from doing it on your own; 3. The reputation of the enterprise / department / Customer's department successfully and effectively implementing innovative projects.

Request for a quote

FERAG AG

Switzerland

The state-of-the-art AGV and AMR vehicles with a complete range of products for intelligent intralogistics solutions are based on proven Quicktron technology. These mobile robots include automated solutions for the handling of shelves, mobile devices, pallets and basket of work without an operator. In suitable projects, this new product range will be combined with Ferag products (Denisort, Deniway, Easychain and Skyfall) into fully integrated solutions.

Request for a quote

WIFERION - A PULS BRAND

Germany

The contactless charging solution for AGV’s, robots and forklifts in industrial environments. Simply stopping your vehicle at the charging position will start your charging process. Thanks to the contact free design, the system may be installed whereever your process requires. There are no trip hazards and charging will start within less than a second. For optimized charging of Lithium batteries a CAN-interface to communicate with your vehicle components is part of the system.

Request for a quote

COGNEX CORPORATION

Germany

The 3D-A5000 offers a variety of fields of view and measurement ranges to accommodate applications in the automotive, consumer goods, and logistics industries. Other features and benefits include: — Patent-pending 3D LightBurst technology enables rapid image acquisition — More than 1.5 million 3D data points detect fine features on parts — High Dynamic Range (HDR) mode captures scenes with high contrast — Powerful 3D tools in VisionPro solve challenging 3D applications — Factory-calibration delivers results in real-world units — Rugged IP65-rated housing provides protection in harsh factory environments

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Highly flexible palletizing solutions due to quick and easy re-configurations • Extremely precise operation ensures high quality palletizing • Use of a great variety of grippers makes for high flexibility • Coordinated concept including material flow environment Articulated Arm Robots offer highly flexible palletizing possibilities and are thus a real economical alternative. Especially profitable when with the corresponding performance two end packaging lines can be palletized by one machine. Articulated Arm Robots from Langhammer come delivered with the complete material flow environment in exact accordance with customer preferences. A turnkey installation from a single source.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Easy programming + maintenance via the PLC: no robot programming skills required • Optimal utilization of space + considerable space saving due to compact design • Highly flexible palletizing solution allows for any number of layer patterns • Layer weights of up to 200 kg possible • Gentle product handling of complete layers • Consistent and proven Langhammer operating concept allows for easy configuration In contrast to conventional systems with fork/clamp grippers, this compact design results in an enormous space saving of up to 40%. The new Articulated Arm Robot AR500 in combination with either Siemens or Rockwell controls guarantees easiest programming and maintenance directly via the PLC. By combining the Articulated Arm Robot AR500 with TheWave Langhammer offers a coordinated concept for the complete material flow, characterized by extreme accuracy & high-quality palletizing – and everything according to customer requirements – ready to go from a single source

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

We use time and consumables much more efficiently with robotic solutions in paint processes. With the decrease in paint usage according to the current situation, we both increase efficiency and keep your employees away from the unhealthy atmosphere of the paint environment by applying standard thickness paint without any errors on the entire surface.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

With our packaging and palletizing solutions, we robotize the end of the line, which is generally the most inefficient process in production lines, without damaging your products, completely avoiding occupational diseases and possible HSSE risks that can be created by heavy products

Request for a quote

B:TECH

Czech Rep.

IMPROVE EFFICIENCY AND ACCURACY OF YOUR OPERATION AND LOGISTICS, REDUCE OPERATING COSTS AND ERROR RATE IN PRODUCTION, PACKAGING AND HANDLING Robotization and automation of processes can quickly and simply solve lack of staff, reduce production costs and error rate. In addition, the industrial robotization can be the first step towards implementation of Industry 4.0 principles in your company. We design robotization and automation of production processes so that they make sense and save your costs and time. We will work out an EFFICIENT SOLUTION to the robotic workstations as well as complete assembly lines RANGING FROM TECHNICAL DESIGN AND SIMULATION TO INTEGRATION INTO THE EXISTING OPERATION. We also provide servicing and maintenance of all our implementation projects. Firstly, we will MEET with you to identify your needs and expectations. Secondly, we will DESIGN ROBOTIC WORKSTATIONS including VISUALIZATION AND SIMULATION.

Request for a quote

INDUSTRIAL ROBOTICS COMPANY

Lithuania

“RoboMill” – one of the most advanced machining devices on the market today. Unique technological basis and exceptional flexibility allow “RoboMill” to automate complex machining processes of components or materials. The workflow automation also helps to avoid accidents that can happen while doing the work manually.

Request for a quoteResults for

Robotic solutions - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Industrial robots (6)

- Robotics (6)

- Construction - Machines & Equipment (3)

- Monitoring and control equipment (2)

- Palletising machinery (2)

- Assembly robots (1)

- Automation - systems and equipment (1)

- Battery chargers (1)

- Brakes, servo-brakes and accessories (1)

- Casting, steel (1)

- Development and research strategy (1)

- Electronics - studies and research (1)

- High-pressure cleaning machines (1)

- Industrial cabling (1)

- Industrial sheet metal work (1)

- Laser - cutting and welding machines (1)

- Machine vision system (1)

- Motor mechanics - hand tools, non power (1)

- Painting robots (1)

- Polishing - machine tools (1)