- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robotic grinding

Results for

Robotic grinding - Import export

ORGECO SPOL. S R.O.

Slovakia

Our company employs state-of-the-art robotic welding and grinding technology, ensuring high precision, efficiency, and quality of our products. Robotic welding allows us to perform complex welding operations with consistent quality, minimize human errors, and increase productivity. Our robotic grinding systems deliver perfect surface finishes that meet even the most demanding customer requirements. Thanks to our advanced technologies, we can offer top-notch solutions for various industrial sectors.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing fan housings - fan house, which constitute a key part of cooling units. We offer a wide range of types and sizes according to individual customer requirements, manufacturing these components from steel, stainless steel, and aluminum. We utilize the latest technologies including laser welding, CNC sheet metal bending, robotic welding, and robotic grinding, enabling us to achieve high precision and efficiency in production. We are committed to adhering to the highest quality standards, ensuring that each product meets all customer requirements. Our experienced and skilled team is dedicated to providing satisfaction and long-term partnerships with our clients.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing sheet metal components according to individual customer requirements and specifications. We utilize state-of-the-art technologies, including laser cutting, CNC precise bending of sheet metal, robotized welding workstations, robotized grinding workstation, and CNC center for rounding and grinding the surface of sheet metal. These advanced tools enable us to deliver products of the highest quality and precision. Whether it's intricate designs or specific dimensions, our technological capabilities allow us to efficiently and reliably meet even the most demanding customer requirements.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of stainless steel sheet metal components, meticulously crafted according to the specific requirements and drawings provided by our customers. Utilizing advanced techniques including laser cutting, CNC bending, robotic welding, and robotic grinding, we ensure the highest standards of quality and precision at a competitive price. Additionally, we offer surface treatment services such as pickling and phosphating through our trusted partners, guaranteeing a comprehensive solution for our clients' needs

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in the production of welded metal constructions tailored to customer requirements. The materials we use include steel, aluminum, and stainless steel. Our processes incorporate cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding. In collaboration with our partners, we also address surface finishing solutions, including powder coating, hot-dip galvanizing, electroplating, pickling, and passivation. We take pride in the quality and precision of our products, ensured by these technological innovations. With our focus on technological advancement, we are capable of meeting even the most demanding requirements of our customers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORGECO SPOL. S R.O.

Slovakia

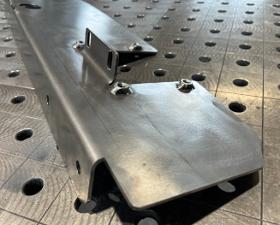

We specialize in producing compact liquid tanks for machinery, ensuring top-quality performance. These tanks undergo rigorous 100% testing to guarantee their tightness. Crafted from sheet metal, our tanks are manufactured using cutting-edge technologies such as laser cutting, sheet metal bending, robotic welding, and robotic grinding. These modern techniques ensure precision and durability in every tank we produce. With our commitment to excellence and advanced manufacturing processes, we deliver reliable liquid containment solutions tailored to the needs of our customers and their machinery. Our dedication to quality control means that every tank leaving our facility meets the highest standards of performance and reliability, providing peace of mind to our customers. Trust in our expertise and innovative approach to manufacturing, ensuring that your machinery is equipped with the finest liquid containment solutions available on the market.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of metal welded brackets according to the individual drawings and requirements of our customers. We are able to provide high-quality products that precisely meet the needs of our clients. Our production is based on the latest technologies in the industry. We utilize laser cutting and CNC bending of sheet metal, which allows us to achieve high precision and repeatability in our products. Thanks to robotic grinding, we are able to achieve optimal surface quality, ensuring consistent and aesthetically appealing surface finishing. One of the key aspects of our production is ensuring a high standard of corrosion resistance and safety for our customers. For this purpose, we use top-of-the-line COSTA machinery, which allows us to round the edges of components with precision and efficiency. This process not only enhances the aesthetics of our products but also increases their durability and resistance to external influences.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

As experts in metal fabrication, we specialize in crafting custom brackets and consoles for a multitude of purposes, precisely tailored to our clients' specifications. Our advanced manufacturing facility employs cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding to ensure the highest quality and precision in every bracket and console we produce. Whether fabricated from steel, stainless steel, or aluminum, our brackets and consoles are engineered to meet stringent standards of durability and performance. Additionally, we offer a variety of surface finishes including powder coating, anodizing, plating, hot dip, and KTL, providing both protection and aesthetic appeal. At every stage of the fabrication process, from design to finishing touches, we uphold a commitment to excellence, delivering reliable and resilient brackets and consoles that exceed expectations.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We are a manufacturer of metal pallets, also known as pallet frames, tailored to individual customer requirements, providing flexibility and a personalized approach. We utilize state-of-the-art technologies such as laser cutting and CNC sheet bending to achieve a high standard of precision and quality in the production of our metal pallets, or pallet frames. Robotized welding ensures consistent and reliable quality of joints, which is critical for the safety and longevity of our products. With the help of robotic grinding, we achieve a smooth and aesthetically pleasing surface on our metal pallets, or pallet frames, enhancing their attractiveness and functionality. Our combination of modern technologies and expertise enables the production of metal pallets, or pallet frames, in a wide range of dimensions and shapes, allowing us to meet even the most demanding needs and requirements of customers.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the custom fabrication of sheet metal components to the exact specifications specified in our customers' drawings. Our advanced technologies, including laser cutting and precision CNC bending, ensure accurate production to customer specifications. In addition, our robotic welding and grinding stations ensure high-quality surface finishes and consistency of production. Thanks to our dedicated CNC surface finishing centre, we can achieve the required material readiness for surface finishing. Our commitment is to deliver products that not only meet, but exceed the expectations set out in the customer's drawings, ensuring the satisfaction and reliability of every part produced.

Request for a quote

GIZELIS ROBOTICS

Greece

Robotic systems assist in such applications thanks to their particularly enabling features. Typical grinding applications include a closed robotic cell to avoid particle dispersion in the surrounding area. A head-bearing robot is located inside as well as various other grinding machines. The robot picks the piece from the feeding area, drives it with precision through all processing stages and places it at the discharge area before it starts all over again by picking the next piece. Depending on the product, a suction system is put in place to keep the robotic cell clean. Robotic grinding is the only option for all related industries since production time is greatly decreased, maximum degree of safety is achieved and, most significantly, it offers flawless quality and consistency to end products. Only companies using robotic systems stand out from the competition, as they can produce optimum products at the lowest possible production cost.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

Cutting, deburring and grinding operations, which are generally carried out with manual operations, are problematic in standardization and very risky in terms of HSSE. With robotic projects, we obtain the most precise results in a safe way.

Request for a quote

STAHL OBERFLÄCHENTECHNIK GMBH

Germany

Grinding on a belt-grinding machine CNC- and robot-controlled grinding Polishing by hand or by CNC- or robot-controlled rolling machines

Request for a quoteResults for

Robotic grinding - Import exportNumber of results

14 ProductsCountries

Company type