- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot technology

Results for

Robot technology - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

This means no more complex computer programmes requiring the knowledge of experienced programmers. No more equipment that is extremely sensitive to high ambient temperatures, thus resulting in the variable quality of manufactured products. No more need for large-scale production operations to ensure that this equipment is cost-effective. The new programming tools available offer a user-friendly approach to robot configuration. Using a simple touch tablet, you can quickly and easily reprogramme your robot, which can be fully and economically operated even for small and medium-sized production runs, without the need to call on a programming expert.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Together with our customers, we develop scalable control and automation solutions for their assembly, laser and ECM lines to meet their requirements. In doing so, we attach great importance to the topicality and future-proof development of the technology used. Programming under SIEMENS SPS, SIEMENS NC, BECKHOFF HMI and robot technology are our specialties. We are experts in realization drive and feedback control engineering, electrical project planning, control-cabinet construction, software development and control engineering.

Request for a quote

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

FÖHRENBACH GMBH

Germany

The versatile control unit for handling, assembly technology, linear robots The unipos 330 is a universal, modular CNC continuous path control for up to 3 axes (interpolating) in connection with a PLC for controlling most reliable applications for machine construction automation technology, machine tools and special applications. Depending on the design, either stepper motors or servomotors are used as axis drives. The integrated panel PC with the LINUX operating system allows convenient programming of your application and the user interface (HMI). Features Interpolating continuous path control for a maximum of 3 servo axes CNC programming using G code 1 to 3 axes / stepper motors or servomotors Processor: 32-bit microcontroller, 400 MHz, without fan 7" touch screen, resolution: 800 x 480 DPI, TFT colour

Request for a quote

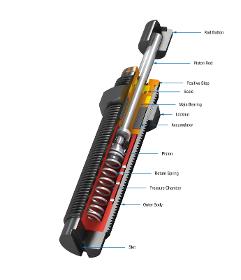

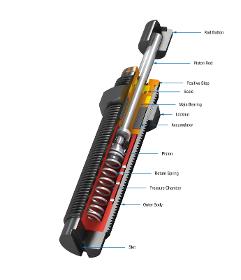

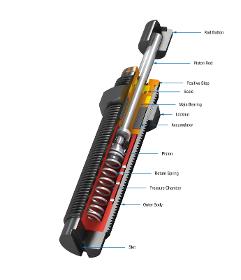

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1.25 Nm/cycle Stroke 5 mm Ideal for compact, efficient designs: The MC5 to MC75 series impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking. The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these minature units. These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1 Nm/cycle Stroke 5 mm Ideal for compact, efficient designs: The MC5 to MC75 series impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking. The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these minature units. These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 0.68 Nm/cycle Stroke 4 mm Ideal for compact, efficient designs: The MC5 to MC75 series impresses users with their reduced dimensions and their very short overall lengths and low resetting forces after braking. The outer body of each damper, produced from one solid piece, are filled with temperature stable oil, offer a continuous thread incl. a supplied lock nut and also have an integrated positive stop. These hydraulic machine elements from ACE, are ready for immediate installation and are maintenance-free. A comprehensive range of energy absorption with a wide range of effective weight potential are further benefits in these minature units. These miniature shock absorbers are perfectly suited to use in applications such as mechanical engineering, medical and electro-technology and robotics.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The fanless PLC with iMX6 Quad Core processor technology combines compactness with longevity and performance. The device has an integrated flash disk and an easily accessible SD card slot. USB interfaces allow the use of additional change-over memories or external peripherals. ; Kuhnke controllers with CODESYS SoftMotion CNC+Robotocs provide the user with extensive project planning options for his motion tasks. Among other things, certified motion modules according to PLCopen and the full scope of the IEC 61131-3 programming interface are available, as well as integrated motion planning with coordinate values for robot positions in different coordinate systems and numerous supported kinematics with convenient configuration, e.g. various gantry robots (2/3/5 axes), bipod/tripod robots, Scara robots. ; Fanless i.MX6-QuadCore processor technology ; Stable, compact housing, DIN-rail mounting ; CODESYS Soft PLC with WebVisu and SoftMotion CNC+Robotics

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

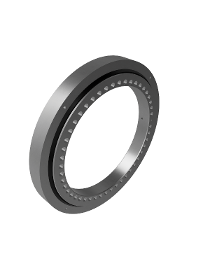

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company employs state-of-the-art robotic welding and grinding technology, ensuring high precision, efficiency, and quality of our products. Robotic welding allows us to perform complex welding operations with consistent quality, minimize human errors, and increase productivity. Our robotic grinding systems deliver perfect surface finishes that meet even the most demanding customer requirements. Thanks to our advanced technologies, we can offer top-notch solutions for various industrial sectors.

Request for a quote

AXON CABLE SAS

France

Axomove® is a range of round composite cables specially designed for robotic technology applications. They are able to meet the most demanding requirements of the automation technology. The main characteristics are as follows : good flexlife and resistance to torsion, small dimensions, small bend radius, resistance to oil and solvents, abrasion resistance, EMI protection. Depending on customer requirements, they can be composed of round or flat primary wires or both Insulation : FEP, PTFE, ETFE, PFA, polyimide, vitax™ , PU, ... Shielding for EMI protection when required

Request for a quote

EMO - ORODJARNA D.O.O.

Slovenia

More than 10,000 designed and manufactured tools Our most important sales product, in terms of excellent human capabilities, 125 years of tradition, more than 10,000 designed and manufactured tools for sheet metal forming, is engineering and design of the most optimal process of structural parts, especially for the automotive industry with modern computer technology, computer-aided machines, laser- robotic technology and acquired certificates for quality, environment, safety of computerization and qualification of employees. Cold Forming Car structural parts manufactured with cold forming in the tool. Cold forming tools are designed with state-of-the-art software, backed by extensive experience in the field of computer simulation and 5 axial CNC programming. We specialize in the production of tools for deep drawing, high strength sheet metal and aluminum.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SINOP SMP

Czech Rep.

Since 2011 we are proud to have robotic laser welding technology (currently 3 welding cells) at our disposal. The laser beam is generated with the solid-state laser source TruDisk with a maximal power output of 4 kW. Laser welding stands for the unrivalled welding productivity and a low heat application. This guarantees a minimal distortion and an outstanding appearance of the weld seam. The clamping fixtures for robotic welding are developed and produces in house. Very small heat affected zone resulting in the low distortion of the components Smooth and symmetrical weld seam High process stability and high welding speed Outstanding weld seam quality with a minimal or no necessity for an additional surface treatment Fixture design and development in house

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Suitable robots for almost every requirement What started with the first "intelligent" actuators at IAI today includes a wide range of industrial robots for all automation technology. The range includes cartesian robot systems, tabletop robots and SCARA robots. Matching controller with all common fieldbus connections complete the offer.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The classic application of industrial robots. The application of wet paint is one of the classic uses of industrial robots. As a specialist for surface coating systems, Rippert naturally offers the full range of solutions in the Ex and non-Ex area. Robots and application technology are integrated into the overall system in relation to the specific customer and his application. Modern software concepts ensure economically optimum operation.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

First installed in July 2019 and improved in 2021, DLyte 10,000 is a modular solution designed for mass manufacturing. It is integrated into any production line where the complete automation of workflows and the production of large batches and parts can be treated efficiently. Based on the patented DryLyte technology, the robot module allows to treat metals and alloys in a fast, and cost-efficient way. To achieve the highest quality results in complex and heavy pieces, it counts with a precise 6-axis mechanical movement, to remove the roughness from the workpieces. DLyte10,000 delivers the full range of electrical parameters, from low to high frequency, parameter concatenation and asymmetric voltage. In addition, it allows the user to search the ideal parameters for its pieces in the library of processes in the Polishing Manager App. The range of applications for the DLyte10,000 are workpieces from the aerospace, energy, oil and gas, shipbuilding, machinery and food industries.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Painting in cleanrooms according to the DIN EN ISO 14644 standard Cleanroom technology Many processes for the application of technically functional coatings for increased resistance to scratching (hardcoat), UV stability, lotus effects, anti-fog or other thin-film applications place high demands on the implementation and function of the coating plant and its components. Thanks to a modular design, optimum plants are conceived in close cooperation with customers and users that minimise faulty coatings caused by particle inclusions and the resulting product scrap or rework expenditure. The plants are designed strictly in accordance with the DIN EN ISO 14644 the standard. In designing the filter stages we orientate ourselves to a particle size with a diameter of 0.5 µm. Built-in components such as conveying equipment, robotics, application technology etc. are adapted by careful selection of the appropriate task. A further criterion in the conception of the plants is fast and efficient cleaning and maintenance, in order to obtain long plant operation times with a constantly good yield. Traditional applications are the coating of diffusers or cover glasses for car headlights or polycarbonate glazing.

Request for a quote

KLN ULTRASCHALL AG

Germany

We work with you to develop the best possible solution for your project based on standard systems or modular functional modules. We have developed solutions for welding, punching, riveting, drilling, wrapping, flanging, handling and many other processes. Your task is most important for us and our technicians will try find together with you a solution meeting the requirements in quality, cycle time and cost. Examples of special systems: • final processing machines for plastic fuel tanks • rotary table machines for vibration welding, infrared welding, ultrasonic welding and hot plate welding • edge-welding machines for textile back injection molded parts • ultrasonic or mechanical punching machines • infrared welding machines in modular design for welding of several parts in one go • fully automated operating cells e. g. with feeding technology and robot handling

Request for a quote

GIZELIS ROBOTICS

Greece

Assembling various components amongst them is a complicated procedure for automation and it is usually delivered by humans. Thanks to the industrial revolution and fast technological development, robotic arms have stepped in and already been established as an essential part of the process given their advantages. There are many types of robotic systems that are ideal for assembling and selecting one is determined by system speed, component weight and maximum operating radius.

Request for a quote

IBG HYDROTECH GMBH

Germany

Combined TV driving and milling technology Patented system - IBG ONLY World's best camera technology for milling robots Fully digitized Automatic error analysis

Request for a quote

PI MAKINA

Turkey

Tower cranes, of which Pi Makina is the first domestic manufacturer, are produced with 6 and 7-axis robot welding manufacturing technology. These easy-to-install and easy-to-assemble cranes are indispensable for construction sites by virtue of their load lifting capacities ranging from 2 to 24 tons, their boom tip lifting capabilities between 750 kilograms and 2 tons, and the working radius of up to 80 meters. With its powerful automation system, ergonomic stairs, and platform design, it provides its users with a comfortable and safe working experience. Pi Makina tower cranes, which have become an important brand of the sector in recent years with their 100% domesticity rate and superior features,.

Request for a quote

MONDRE LOGICS LTD

United Kingdom

We provide safe, flexible, automation solutions incorporating the latest robotics technology to streamline manufacturing and reduce costs.

Request for a quote

NEBEXT

Spain

Discover the latest solutions on industrial automation, robotics and technologies to transform your business

Request for a quote

FERAG AG

Switzerland

The state-of-the-art AGV and AMR vehicles with a complete range of products for intelligent intralogistics solutions are based on proven Quicktron technology. These mobile robots include automated solutions for the handling of shelves, mobile devices, pallets and basket of work without an operator. In suitable projects, this new product range will be combined with Ferag products (Denisort, Deniway, Easychain and Skyfall) into fully integrated solutions.

Request for a quoteResults for

Robot technology - Import exportNumber of results

31 ProductsCountries

Company type

Category

- Industrial robots (3)

- Assembly robots (2)

- Automation - systems and equipment (2)

- Construction - Machines & Equipment (2)

- Foams, rubber (2)

- Robotics (2)

- Access control - systems and equipment (1)

- Bearings, roller (1)

- Congresses, seminars, receptions - organisation and services (1)

- Construction, industrial - contractors (1)

- Cutting, plastics - machinery (1)

- Electric cables (1)

- Finished Metal Products (1)

- Food Processing (1)

- Goods lifts (1)

- Grinding - machine tools (1)

- Machine tools - metal machining (1)

- Motor mechanics - hand tools, non power (1)

- Palletising machinery (1)

- Pipes and tubes - ferrous metal (1)