- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rinsing machines

Results for

Rinsing machines - Import export

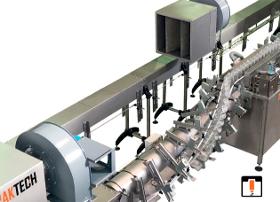

TRAKTECH

Spain

ROTRAK’s monoblock unscrambler and rinser is one of many solutions offered by Trakteck to production companies, integrating two essential elements for the start of bottling lines: A monoblock rotary unscrambler and a rinser, with the aim of supplying empty bottles to the filler. The production company can choose between different positions in the rotating unscrambler and different variants of rinsers developed by Traktech, adapting them to production needs. Integration of Traktech’s bottle unscrambler and the rinser in a single machine allows essential elements to be shared, such as perimeter protection, the electrical panel or the control system. This machine is a useful solution for companies that need to guarantee bottles are well cleaned at the start of the bottling line, before reaching the filler.

Request for a quote

TRAKTECH

Spain

The Side-Grip Bottle Rinser Machine by Traktech have been developed to guarantee production companies perfect internal cleaning of empty glass, plastic or metal containers, through a dual simultaneous blowing and suction system with ionized air, which with its ion charge, enables air circulation inside the empty containers, expelling all the particles of dirt. The series of Side-Grip rinser can be configured by input and output of empty containers, guaranteeing maximum cleaning.

Request for a quote

TRAKTECH

Spain

The Rotary Bottle Rinser by TRAKTECH is a compact solution that enables the inside of empty glass, metal or plastic containers to be cleaned, using ionised air, effective for filling lines in companies producing 3,000 – 4,000 bottles per hour (bph). The ingenious input system for containers in the Rotary rinser, that places the empty containers in a vertical carrousel, allows the surface dedicated to cleaning the containers be as small as possible. Production companies maximise productivity of their filling lines per square metre and improve the utility of the production area.

Request for a quote

TRAKTECH

Spain

The Twist Rinser, developed and patented by Traktech, is a system for cleaning the inside of PET (Polyethylene terephthalate) bottles, for companies with lines of high production. It is the only rinser on the market installed on the air conveyor, located between the blower and the filler, significantly reducing production costs and possible incidents in the filling line.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-WF Linear type Bottle Rinser by water is widely used for rinsing the new glass bottle and jars before filling. The rinsing can choose pure hot water or normal temperature purified water. The water after cleaning the bottles and recycling into the water tank for purify and heating again to reduce the water comsuption.The ultronic device is for option to meet the high requirement, Servo system bottle rinser Servo motor driven the bottle clamper to turn up 180 degree, the turning speed is frequency converter control. The rinse spary head are specially designed for different types of containers, ensure 100% rinsing the inside of the bottles. Rinsing head will insert into the container for cleaning. The machine is frequency speed control, change bottles no need additional changeover parts. A high pressure water pump and a water recyling pump ensure the rinse pressure and recyling water in time

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AUROMAK MAKINA

Turkey

The multiprocess parts washing machine with rotating basket is a cleaning device for industrial use.This machine has been designed to ensure that parts are washed effectively and quickly. The main feature of the machine is the rotating basket system.The pieces are placed in a specially designed basket and the basket is washed by rotating it on a rotating mechanism. In this way, each surface of the parts is cleaned equally and a more effective washing process is performed. The Multiproces feature allows different cleaning stages to be performed on the same machine.For example,you can perform different operations such as detergent, spraying, brushing and rinsing on a single machine. Multiprocess parts washing machine with rotating basket is ideal for cleaning parts used in automotive, machinery, electronic equipment and similar industries. It optimizes the production process and increases quality by providing fast, effective and reliable cleaning.

Request for a quote

TASK ITALY SRL

Italy

The SC-10 rinser, consisting of a rotating table with intermittent movement at 10 positions, allows for the prevention of biological contamination in bottles and jars caused by the presence of dust, leaves, small insects, and the risk of serious incidents due to possible glass fragments inside the containers. It is possible to insert and remove bottles from the front position. The spray of rinse water or sanitizing solution occurs only when the bottle is present, thanks to a contact microswitch. For the use of a recirculating solution, a kit with a recovery tank, pump, and connecting pipes is available. The machine is equipped with a filter for the rinse solution with a 0.45-micron microfiltration cartridge. It is also available in a 20-position version and a blow-only mode. Production: 700 pieces per hour.

Request for a quote

LABOREX

Belgium

Say goodbye to time-consuming manual cleaning and hello to the Laborex spray washing machines! Our machines automatically clean, rinse, degrease, and dry industrial parts made of metal or plastic, allowing you to focus on other tasks worry-free. Looking for an external cleaning solution for your parts? Look no further than our Laborex rotating spray washing machines! With a simple setup, you can place your parts in the basket and select a washing program. Our machines use a combination of chemicals, washing duration, temperature, pressure, and flow rate to ensure that your parts come out perfectly clean every time.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN- KBN2 series parts washing machines are especially used for washing parts that require rinsing, passivation or other processes after washing, as well as large and heavy parts. While it is desired that there is no oil and other impurities on the surface before assembly or packaging in enterprises and factories that produce parts in series, it may also be necessary to remove the washing chemical used in the 1st stage from the surface of the part depending on the place of use of the part. For this requirement, a 2nd stage rinsing or a similar application is mandatory. Our KBN 2 series part washing devices are a special device containing more than 1 tank and/or bath. The parts placed in the device are rotated on its own axis by means of the washing basket, while pressurised detergent hot water is sprayed. Thanks to the pressure, temperature and chemical effect, all oil and dirt on the part is cleaned.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Cleaning machine Clean-o-mat SP 80 - 2 T for turbine components out of the aircraft industry Toploader SP 80 - 2 tank machine with additional rinsing with fresh water and impulse blowing off for turbine components out of the aircraft industry

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The approved and economic system of this multi-tank-machine offers various possibilities for all applications in the area of the production and manufacturing industry. Most different process steps like cleaning, rinsing, inter-rinsing and drying makes the machine the all-round talent. The PERKUTE system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Simple operation Adjustable feed fork-lift facility incl. 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Electronic basket drive Tank cover in the return flow, filter basket incl. Long wash liquid service life due to the skimmer (washing tank) Programmable operation operating counter incl. Automatic steam extraction by air blower Powerful washing pump in the washing- and rinsing tank High permissible basket load 2" socket slide valve for the tank emptying Safety limit switch at cover Separate washing- and rinsing tank

Request for a quote

SODASAN WASCH- UND REINIGUNGSMITTEL GMBH

Germany

The high-performance formula with natural citric acid removes limescale deposits. Dosage Undiluted use : Apply to taps, tiles, or shower walls and let product take effect. Rinse off thoroughly. Diluted use : Add 200 ml to 1 litre of water and use in steam irons, kettles, coffee and espresso machines, etc. Rinse out several times. For descaling washing machines : Add 1 litre to the machine and run a 60°C cycle without laundry. For descaling dishwashers : Add 1 litre to the machine and run without dishes. Please observe the manufacturers’ instructions! aqua citric acid

Request for a quote

OMG DENGE DIS TIC LTD.

Turkey

capacity between 2.400 - 32.000bph neck handling system bottle volumes 0,5 lt - 1,5 lt, 5 lt, 10 lt, 19 lt screw cappers for carbonated & non-carbonated products

Request for a quoteResults for

Rinsing machines - Import exportNumber of results

14 ProductsCountries

Company type