- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- resin casting

Results for

Resin casting - Import export

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The Systems comprise the entire casting process: Preparation of the material components resin and hardener (conveying, homogenization, degassing), production of the reactive mix and casting of the parts under vacuum/atmosphere. Any resin system can be processed, also with strongly disproportional mixing ratios.

Request for a quote

EAE ELECTRIC

Turkey

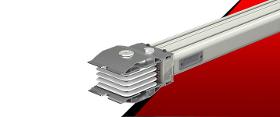

Cast Resin BusbarBusbar trunking systems (E-Line CR Busbar: Cast Resin Busbar) provides the transfer and distribution of electrical current between 630A and 6300A. Explosion proof protected and compatible with E-line KX busbar modules. IP 68 protection class. The "DUROCOMP" synthesized material which has a high temperature and mechanical working strength composed of specially selected pure silicon minerals and epoxy resin, thereby protecting the E-Line CR busbar from external impacts.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Together with the Fachhochschule Münster – University of Applied Sciences we are working on ALWA PERM (patent No. 2583995). This is a metal-filled casting resin for producing a porous, resin-bound mould. These materials are applicable in the areas of thermoforming, the ceramic industry, intake moulds and devices, pneumatic cushioning, the filter industry, etc. ALWA PERM allows a castable production of porous metallic materials with a binder for the first time. The system offers a highly accurate mould surface reproduction. The profile characteristics goes far beyond the current state of the art. NO MORE DRILLING OF VACUUM HOLES! NO DAMAGE OF THE MOULD SURFACE DUE TO DRILLING HOLES

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life: *ALWA MOULD SLV 3 ~ 3 min. pot life *ALWA MOULD SLV 9 ~ 9 min. pot life

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD P is a cold curing casting resin for the production of porous moulds, slabs and blocks for the ceramic industry. It is a porous and high-strength plastic, which is well-suited for high pressure casting applications. ALWA MOULD P can be used in various areas of the tableware and sanitary ceramics, technical ceramics, plastic mould procedure as well as various filtration processes. The high stability and defined porosity of the material allows highly accurate mould surface reproductions. With ALWA MOULD P various geometric moulds for filtration processes of suspensions can be produced. ALWA MOULD P can be used for ceramic slip pressure casting procedures. In this procedure, water is removed by a filtration process of a clay suspension (slip), so that an increasing clay layer is built on the mould wall over time. The moulds, slabs and blocks of ALWA MOULD P are easily machinable (e.g., drilling, milling).

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Aluminium perforated sheets are used in order to reinforce the casting resin moulds.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The patented casting resin system ALWA MOULD D consists of two resin components and an aluminium filler. The fast curing of the material allows to produce your own technologically highest quality moulds in just a few hours. As our material is very good castable, compact moulds of any desired volume can be made from our product, such as acrylic baths, boats, etc. (<1 kg – 2500 kg). In comparison to other materials (e.g., glass fibre reinforced plastic), the system is more temperature-resistant, allows castings without air bubbles and does not have to be post-cured. Furthermore, the finished mould is easy machinable (e.g., drilling, milling, grinding, planning, sawing, turning, etc.). ALWA MOULD D moulds can be modified with repair filler, so that a fresh view can be created at an early stage of a new design process and prototypes can be examined at short notice.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA repair filler (art. no. 5100001) is used in order to repair casting resin moulds. The filler is mixed with 1 – 3 % hardener powder.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA HT RESIN is a resin-based on isocyanate and epoxy (EP), which reacts after adding a catalyst. ALWA HT RESIN offers a range of possibilities for producers of fibre-reinforced materials (e.g., glass fibre, kevlar and carbon), semi-finished and finished goods. The system is also suitable for prepreg and reaction compounds. ALWA HT RESIN is particularly interesting for the aerospace and aircraft industry as well for the rail transport, automotive and electronics industry. The application area of epic resins are electro casting resins, lamination and injection technology (RTM procedure), vacuum infusion, casting and ramming compounds, impregnation resin, casting and injection moulding process as well as prepreg technologies, among others. ALWA HT RESIN is offered in two versions. *ALWA HT RESIN M100 with approx. 50 mPa s *ALWA HT RESIN M2200 with approx. 2200 mPa s The resins can be mixed with one another which enables a flexible adjustment of the viscosity.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Heat-resistant wheels and castors are used in a variety of areas, from the food industry to medical engineering and other industrial applications. Requirements for these wheels and castors are equally diverse: in addition to withstanding high temperatures, they also need to meet hygiene requirements, resist corrosion and support heavy loads. Blickle has eight different wheel series in its standard range to cover these applications. These include series with specialised, highly heat resistant solid rubber and a pressed steel or synthetic rim. Wheel series made of nylon, phenolic resin and cast iron round out the range of heat-resistant wheel series. Temperature resistance ranges from -200°C up to +600°C, depending on the wheel series.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material:Grey Iron: GG15, GG20, GG25, GG30 Ductile Iron: GGG40, GGG45, GGG50, GGG60, GGG70 Process: Resin sand casting, Film-covering sand casting, Clay sand casting, Hand molding and machine molding Application: Agricultural machinery, Off-shore industry, Printing machinery, Waste treatment machinery, Concrete plant equipment, Packaging machinery, Pumps

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of most different materials sliding on resp. rubbing against each other like metals, wood, ceramics, rubber as well as paintable plastics For packing machines, sliding areas in the plastics and textile industry, rollers and chutes in the transport range, etc. Non-stick coating of all kinds of sealings and sealing areas to avoid sticking, squeaking of soft on hard materials (e.g. rubber on glass), for water-repellent impregnation of absorbing materials or as separating film for casting resin applications Advantages and benefits Thin, tack-free separating film with very good adhesive properties on prepared surfaces Best suitability for low-friction lubrication of all kind of materials in contact Colourless and odour-free antifriction coating with non-stick properties

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of the most varied materials sliding on top of or rubbing against each other (such as metals, wood, ceramic, rubber, and also adhesives or paintable plastics) Anti-stick coating of seals or sealing surfaces of all kinds to prevent sticking-on To cure the squeaking noises of soft on hard materials For water-repellent impregnation of absorbent materials Separating film in cast resin applications Advantages and benefits Dry, non-soiling film Highly effective due to good adhesion to prepared substrates Colourless and odourless low-friction coating with non-stick properties Prevents frictional corrosion Dries at room temperature

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of the most varied materials sliding on top of or rubbing against each other (such as metals, wood, ceramic, rubber, and also adhesives or paintable plastics) Anti-stick coating of seals or sealing surfaces of all kinds to prevent sticking-on To cure the squeaking noises of soft on hard materials For water-repellent impregnation of absorbent materials Separating film in cast resin applications Advantages and benefits Dry, non-soiling film Highly effective due to good adhesion to prepared substrates Colourless and odourless low-friction coating with non-stick properties Prevents frictional corrosion Dries at room temperature Also available as spray version OKS 571

Request for a quote

EAE ELECTRIC

Turkey

IP68 Aluminium Housing Cast Resin Busbar (600A...6300A)Aluminium housing covers the “DUROCOMP” composite material that is manufactured from specially selected pure silicium minerals and epoxy resin and has superior temperature and mechanical operation features and insulates the E-Line CCR Busbar from external elements.

Request for a quote

EAE ELECTRIC

Turkey

MV Busbar (Medium Voltage Busbar) Easy Assembly E-Line MV Busbar, manufactured with state of the art technology starting at 12 kV and 24 kV. Ensures safe and effective power transmission. MV CR is manufactured within a single frame as Al and Cu conductors are embedded in the insulation material which consists of an alloy of exclusively selected silicon minerals and epoxy resin. Busbar system (Medium Voltage - Cast Resin Busbar) is designed to perform at 12 kV and 24 kV. It is manufactured for use up to 5700 A as a standard application.

Request for a quote

ASBER GMBH

Germany

Discover our handmade table made of solid walnut and epoxy resin! The product dimensions are 90 cm long, 65 cm wide and 74 cm high. Unique design: The combination of natural walnut wood and artfully cast epoxy resin makes every table unique. Handcrafted with attention to detail: The careful workmanship and attention to detail guarantee the highest quality and longevity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RUHLAMAT GMBH

Germany

Encapsulation is the method for protecting the chip and wires against mechanical stress and environmental influences. For this purpose, cast resin is dispensed and then cured by UV light or heat, depending on the type of resin. The PowerSeal offers highest quality and maximum speed for the encapsulation of chip modules with up to 40,000 modules/hour. PowerTest - Chip Module Test System The inspection of IC modules for smart cards and RFID devices, based on parametric and functional testing, is an integral part in the production flow and quality assurance. The PowerTest is designed for high-speed testing and encoding of chip modules on 35 mm tapes. The system is also perfectly suited for initialisation and personalisation of IC modules, including OS loading. GTL700 - Glue Tape Lamination System The GTL700 is a highly reliable and flexible system for glue tape lamination of chip module tapes in preparation for the hot melt implanting process. The very efficient system can...

Request for a quote

HARZ LABS, LLC

Russia

Designed for printing models, used for direct casting. Zero ash content and ready to use in shock cycles makes it possible to obtain high quality castings

Request for a quote

HARZ LABS, LLC

Russia

Designed for printing models, used for direct casting. Zero ash content and ready to use in shock cycles makes it possible to obtain high quality castings

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The Systems comprise the entire casting process: Preparation of the material components resin and hardener (conveying, formulation, homogenization, degassing), production of the reactive mix and casting of the parts under vacuum/atmosphere. Any resin system can be processed, including fillers, and also with strongly disproportional mixing ratios.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The casting lines comprise formulation, preparation, mixing, metering and casting of the parts. Also included is a pre-heating zone for the parts resp. molds prior to the casting devices as well as gelling and curing ovens systems. Fully automatic flow of the parts/workpieces through the entire process, from pre-heating to curing.

Request for a quote

JOST CHEMICALS GMBH

Germany

fluid 040 is an NSF- M1 registred, silicone- and solvent-free, release agent. The M1 classification is the highest approval by NSF for release agents, similar to H1 for lubricants and anti-corrosives. fluid 040 can be used for all types of thermoplastic and thermoset casting resins, but especially for plastics which are sensitive to tension cracks. The maximum operating temperature of fluid 040 is 170°C.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

You manufacture sensitive electronic products, such as power semiconductors, diodes, diesel injectors and components for medical equipment. For casting purposes, you need systems that guarantee perfection and absolute freedom from voids with minimum casting quantities. Our Micro Casting Systems: Accuracy: Absolutely error-free casting of the smallest quantities; casting quality tolerance less than 0.01 g. Flexibility: Suitable for highly filled, abrasive casting resins under vacuum or atmosphere. Control: Patented dosing control unit for plant and process monitoring; glass cylinder design also allows direct observation of the preparation process.Compatibility: Modular design; cell construction makes it ideal for integration into existing production lines.

Request for a quote

INSETO (UK) LIMITED

United Kingdom

DELO-DUOPOX are two part epoxy resin adhesives for bonding, casting and sealing of joints. Providing excellent adhesion to many materials, these two part epoxies are ideal in stressed or extreme conditions, including automotive and engineering applications. Two part epoxies are cold-cured, high-strength materials, which can be used where curing with heat is not an option. They cure when the two components are mixed together in the correct ratio. Product dependant, most versions are available in DELO-AUTOMIX cartridges, which present the two epoxy components (resin and hardener) in the correct ratio via a dispensing / mixing cannula. A wide range of curing properties are available, with rapid cure versions that are firm to touch in less than 10 minutes, to versions that are firm to touch in 8 hours. They offer high chemical resistance and are available in a wide range of viscosities. ** Click for more **

Request for a quote

INSETO (UK) LIMITED

United Kingdom

DELOMONOPOX epoxies are one part, heat cured epoxy resin adhesives for bonding, casting and sealing of joints. The epoxy resin adhesives are high strength materials that can be used as alternatives to riveting, welding and brazing in high stress applications. Epoxies exhibit excellent adhesion to metals, ferrites and ceramics. Special advantages of epoxies include their resistance to temperature, chemicals and low water absorption. They will also protect against corrosion. The epoxy resin is supplied ready to use with no mixing required. Curing occurs in 15-75 minutes @ 130-180 degrees C. Versions are available with good flow properties or with high run-off resistance. ** Click for more **

Request for a quote

ACP INTERNATIONAL TRADE - ACP DANISMANLIK VE TICARET LTD -

Turkey

Our transformer range : - Hermetic type distribution transformers - from 25kVA to 4000kVA - Conservator tank distribution transformers - from 25kVA to 8000kVA - Cast resin dry type transformers - from 25kVA to 10.000 kVA - Power transformers - from 2500kVA to 16000kVA - Box and special type transformers - Shunt reactor, Amorphous, Ground transformer All products are manufactured in high quality according to international standards.

Request for a quoteResults for

Resin casting - Import exportNumber of results

29 ProductsCategory

- Synthetic resins (5)

- Electric and electronic components - machines for manufacturing (4)

- Electrical systems and equipment (3)

- Silicones (3)

- Epoxy resin (2)

- Resins (2)

- Cast iron items (1)

- Electric transformers, converters and rectifiers (1)

- Furnaces, ovens and kilns, electric (1)

- Plaques and signs (1)

- Wheels, castors and rollers (1)

- Wood and furnishing - treatment and protection (1)