- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recipe adjustment

Results for

Recipe adjustment - Import export

MOSCA GMBH

Germany

• SoniXs Utrasonic narrow sealing unit in standard-7 version • B&R PLC control • Easy strap coil change and threading system • Strap end detection with ejection of remaining strap • Energy-saving drives • Adjustable strap tension via webHMI • Low-wear, controlled strap path system • 4 castors, 2 of them are lockable • Quick strap coil change • Flexible dispenser alignment • 3 definable recipes for quick adjustment of parameters during product change • CE marking inclusive conformity declaration

Request for a quote

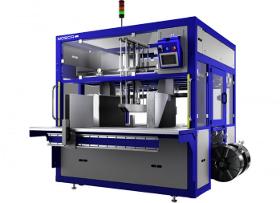

MOSCA GMBH

Germany

• Inline strapping parallel to flute • SoniXs Ultrasonic needle sealing unit • Automated setup system resets to the dimensions of the first bundle of the new size [Teach-In] • 6-sided electromechanical package alignment • Potential-free contacts to upstream and downstream machines • Siemens PLC control with touch panel • Stand-by-mode reduces wear and energy consumption • Lateral automatic adjustment device • Automatic machine adaptation to package dimensions via adjustable recipes [500] • Sealing unit removing device

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The trimming saw is installed downstream of the last surface-layer mat former, cutting the strand mat precisely to the required width. Two motor-adjustable saws, one each located on either side of the belt, cut the strand mat to the dened width. The trimming waste is discharged through a hopper and recycled to the mat former bins. Features Motor-adjusted saw blades incl. distance measurement Movable mat edge retainers to ensure high-quality cuts Lateral pressure rollers ex saw compact and smoothen the mat edge Movable extraction system adjustable to mat thickness Advantages Recipe-related adjustment of all adjustable axes Eective strand extraction

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

3D-MICROMAC AG

Germany

The microVEGA™ xMR system provides high throughput laser annealing for monolithic magnetic sensor formation. A highly flexible tool configuration, the microVEGA™ xMR can accommodate both Giant Magnetoresistance (GMR) and Tunnel Magnetoresistance (TMR) sensors, as well as easily adjust magnetic orientation, sensor position and sensor dimension—making it an ideal solution for magnetic sensor production. The microVEGA™ xMR uses on-the-fly spot and variable laser energy to provide selective heating of the pinning layer in each sensor in order to “imprint” the intended magnetic orientation. Magnetic field strength and orientation is adjustable by recipe, while high temperature gradients ensure low thermal impact. This allows sensors to be processed directly next to readout electronics as well as closer together, and enables the production of smaller sensors—freeing up space for processing more devices per wafer.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-40

Results for

Recipe adjustment - Import exportNumber of results

7 ProductsCountries

Company type