- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rail clamp

Results for

Rail clamp - Import export

IGUS® GMBH

Germany

DryLin® measuring system With display with clamp Fix rail or carriage Guide: DryLin® W DryLin® W - Digital measuring system DryLin® measuring system Ready-to-fit measuring device for external signal output Resolution 0,1 mm Accuracy +/- 0,025 Small sensor with integrated unit drylin® WKMEX measuring system with external output DryLin® measuring system With display with clamp Fix rail or carriage Guide: DryLin® W DryLin® W - Digital measuring system DryLin® measuring system Ready-to-fit measuring device for external signal output Resolution 0,1 mm Accuracy +/- 0,025 Small sensor with integrated unit drylin® WKMEX measuring system with external output

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

NORELEM FRANCE

France

Housing steel. Clamping lever plastic. Threaded spindle grade 12.9. Version Housing nickelplated. Clamping lever, spindle black oxidised. Note Manually operated clamping elements for static clamping tasks. Manual clamping process using the freely adjustable clamping lever. The floating clamp ensure symmetrical application of force onto the rail. Up to 50,000 static clamping cycles (B10d value). In general, a friction connection is created between the clamping element and the the linear guide on the open faces of the profile guide rail so that the ball guide tracks are not damaged. The retaining force is tested on an oil smeared profile guide rail. An adapter plate, dependent on the type of carriage used, is required for height adjustment.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Process Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family PLK clamping elements are more compact than the Series PL components. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and space-saving. Thanks to the patented spring steel plate system, the LOCKED-Family PLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. LOCKED PLK achieve 100 % clamping force due to the steel pads that are used, even on greased rails. The clamping elements represent the maximum holding forces. Whether in the 4 or 6 bar version, they are good for up to 1 million cycles.

Request for a quote

SPIROL

Germany

A fuel injection systems manufacturer used two steel brackets to clamp the fuel rail to the top of the engine. The customer was looking at changing these brackets to plastic to reduce costs. In order to prevent deformation of the plastic bracket during the tightening of the bolt, a Compression Limiter was required. The customer originally investigated the use of a machined Compression Limiter, but the savings from changing the metal bracket to plastic would have been lost considering the high price of the machined Limiter. The customer approached SPIROL to help provide a lower cost solution for the Compression Limiter. SPIROL recommended the use of a standard CL200 Compression Limiter based on the rated proof load of the bolt used in the assembly. This roll-formed Compression Limiter is a fraction of the cost of a machined Compression Limiter. In addition, the flexibility of the roll formed Limiter enabled the customer to widen their hole tolerances further reducing assembly costs.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Load-supported solar mounting frame for penetration-free roof mounting of PV modules as part of an extensive solar green roof build-up where retention volume and discharge delay are required.Available in inclines 10°, 15° and 20° Stability of the overall system proven in accordance with Eurocode 1 and 9. Property-specific proof of stability can be provided Consisting of base plate, bracket and Water Retention Box WRB 80FMA with capillary columns Supplied with associated module quick mounting rails, module clamps, rail connector set and wind bracing. Can be used in both a south-facing and an east-west orientation

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

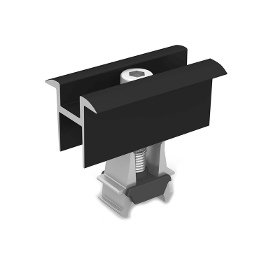

The middle clamp 2.1 Click is a practical and simple component for the Alumero pitched roof system. It is suitable for module frames with a height of 30 – 45 mm. After clicking into the profile rail, the clamp sits securely and can be easily pushed to the side for installation. The clamp is delivered completely pre-assembled.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

The middle clamp 2.1 Click is a practical and simple component for the Alumero pitched roof system. It is suitable for module frames with a height of 30 – 45 mm. After clicking into the profile rail, the clamp sits securely and can be easily pushed to the side for installation. The clamp is delivered completely pre-assembled.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

The middle clamp 2.1 Click is a practical and simple component for the Alumero pitched roof system. It is suitable for module frames with a height of 30 – 45 mm. After clicking into the profile rail, the clamp sits securely and can be easily pushed to the side for installation. The clamp is delivered completely pre-assembled.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Load-supported solar mounting frame for penetration-free roof mounting of PV modules as part of an extensive solar green roof build-up.Available in inclines 10°, 15° and 20° Stability of the overall system proven in accordance with Eurocode 1 and 9. Property-specific proof of stability can be provided Consisting of base plate, bracket and Drainage and Storage Board FKD 25MA. Supplied with associated module quick mounting rails, module clamps, rail connector set and wind bracing. Can be used in both a south-facing and an east-west orientation

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

The K2 universal module middle clamp OneMid is a practical and simple component for the K2 system. It is suitable for module frames with a height of 30 – 42 mm. After clicking into the profile rail, the clamp sits securely and can be easily pushed to the side for installation. The clamps are compatible with the K2 systems Single Rail, Cross Rail*, Speed Rail, Multi Rail and Solid Rail.*

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

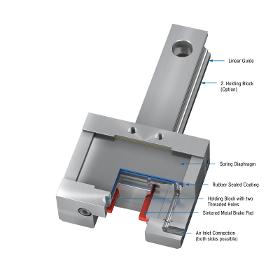

Rail Clamping for Z-Axes Holding force 1,500 N Innovative and BG certified: The pneumatic clamping elements LOCKED LZ-P have been specially designed for safe, reliable clamping on the vertical or Z-axes. The wedge principle makes sure that the gravity loaded axis does not drop. The brake wedges are pushed on both sides against the flat parallel surfaces of the guide rail in case of a loss of pressure. Initially developed for Bosch Rexroth rails in sizes 15 and 25 mm, a test certificate from the trade association was awarded after extensive tests on these clamping elements. Further certifications from other rail manufacturers and sizes are prepared and can be implemented within the shortest time. Users achieve holding forces of up to 2,500 N.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

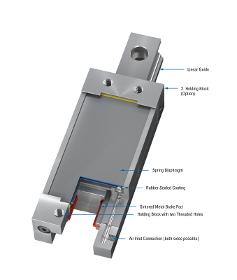

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

ALUMERO SYSTEMATIC SOLUTIONS GMBH

Austria

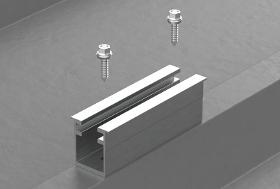

Simple mounting on aluminium and steel trapezoidal sheet roofing Non-shearing attachment via special drilling screws Pre-installed EPDM rubber provides additional sealing between roofing and short rail Module mounted horizontally Clamping on the long side of the module Designed for roof gradients of 5° to 25°

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Clamping clips for guide rails acc. to DIN 15313 galvanized surface * not acc. to DIN 15313 Type W (only on inquiry): Please find results of calculation of stability in our download area:

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Clamps to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These clamps are available in a range of styles and applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Maximise your machining envelope High precision and high clamping force Wide range of accessories for flexibility Clamp single large or multiple small workpieces Workstops to suit OK-Vise Multi-Rail. Multi-Rail can accommodate OK-Vise clamps, stops, parallels and other accessories to clamp multiple components and maximise your milling work area. All the clamping and location elements on the rail can be positioned according to the size and shape of the workpieces to swiftly adapt from clamping multiple small workpieces to clamping single large workpieces. These stops are available in a range of styles and applications.

Request for a quote

ABS SAFETY GMBH

Germany

This temporary guard rail system was specially designed for pitched and flat roofs and is simply hooked onto the gutter or parapet. Any force exerted on it is distributed through its special facade supports. This lightweight guard rail, which is made of high-quality aluminium material, weighs less than 10 kg per meter. EN 13374:2013, C Designed for temporary usage Also suitable for overhanging roofs ≤ 1 m Lightweight and easy to transport Can be easily adapted to fit your architecture

Request for a quote

NSGATE

Russia

The NSBon-01 mounting kit is designed for quick and reliable mounting of the NSB-xxyy | NSP-xxyy | NSV-xxyy | NSE-xxyy series electrical enclosures on circular or rectangular poles. The components of the mounting kit are made of zinc-plated sheet steel and stainless steel. There are two options of lengths of clamping straps, for standard diameter poles up to 190 mm and enlarged diameter up to 300 mm. In the equipment of NSBon-01 includes two mounting rails, two clamping straps, four clamping brackets and the accessories. The pole mounting kit, by default, is designed for 600 mm wide electrical enclosures. By cutting the rail to length or drilling additional holes on the cabinet, the NSBon-01 mounting kit may also be fitted to larger and smaller electrical enclosures.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Cable protection tubes for industry with different properties: With our corrugated tubes, threaded tubes, protective hoses and connection fittings, you are well equipped for all eventualities. They easily withstand both low and high temperatures and also have excellent fire protection and flame properties. Many of our products for industrial cable protection systems are also distinguished by the following features: self-extinguishing halogen-free cadmium-free low flue gas emission weatherproof chemical permanence antistatic Accessories for your industrial cable protection: Of course FRÄNKISCHE Rohrwerke also supplies the appropriate accessories for your industrial cable protection. Mounting clips (with and without base) Mounting rails System holder (Corrugated) pipe clamps PETP - pipe edge protection v.m. Our products for industrial cable protection systems are suitable for all industrial pipe systems from our range.

Request for a quotePOUGET

France

USE : - Fast Tightening of Fishplates on Track (or on Work-Sites) - Tightening of Stopping Shoes. ADVANTAGES : Allow the freely circulation of the Heavy Machines on Track. (Ballast Cleaning Machine, 64 N Model) "SNCF" Model Standard Clamp of Fisplates - Ref. 64 - Body in forged Steel - Tightening Screw in hardened steel with 38 mm Flat Hex Ends - Ø 22 mm Centring Pins - Tightening Screw Stroke : 100 mm - Paint yellow varnish - Net Weight : 8 Kg Small Size Clamp of Fishplate - Ref. 64R - 35 CD-4 Steel - Tightening : 160 mm - Net Weight 8.5 Kg Flat Steel C-Wrench Clamp of Fishplates - Ref. 64N with 2 x Ø 40 mm Hex Head Socket Screws and Ø 22 mm - Weight = 9 Kg ( Doesn't engage the Track Gauge) OPTIONS : Spare Parts for Clamp of Fishplates Model 64 : * Ø 22 mm Centring Pins - Ref. C-22 * Short Tightening Screw - Ref. V-33 * Long Tightening Screw - Ref. V-34 Clamp for 230 mm Tyre-Rail - Ref. C-230 Clamp for 250 mm Tyre-Rail with 2 Fast Tightening Screws - Ref. C-250

Request for a quote

DAXI SA

Belgium

The elastic track application "Railflex" for crossing levels is characterized by a complete rail insulation carried out thaks to an application on continuous elastic boot and an elastomer rail clamps fixing. Therefore, the direct contact between the rail and its steel support is avoided. Main assets of elastic material: -Very high ability to support loads -Very high ability to put power into store and to clear it -Excellent tiredness endurance within the framework of repeated use -High strength to impacts, even under negative temperatures -Good strength to chemical agents and humidity -Very high strength to cuts and abrasion -Excellent maintenance of the specifications during time (not much ageing) The Railflex system is acting bith dynamically and kinematically. 1. DYNAMIC : The vibrations due to the wheel rolling on the rail are filtered by the elastomer supports and their transmission to foundations is reduced thanks to the absorbing effect of the insulating material. The foundation is less in demand, its deterioration is slowed or stopped. Moreover, as the rail is supported elastically, the dynamic impact ratio (wheel on rail) is lowered, the wheel is less "agressive" towards rail which lead to a reduction of the wheels and rails wear. 2. KINEMATIC : When a rail fixed accordingly the Railflex system is subjected to a transverse use at rail top level, the rail moves a little bit aside while it bows down lightly. This rails over-gap changes the kinematic conditions of the naturally curved axle's position effect and a more energetic return to the middle of the track in straight line. These effects are also very favorable to the reduction of wheels and rail wear. Adjustment of the « RAILFLEX » system to road crossing. Description : - The system described hereafter offers the following assets : quickness of implementation thanks to a maximum prefabrication ; quick implementation of railroad and road traffic ; easiness of rail substitution without road destruction ; no maintenance. - The rails are put down on 2 steel gutters. - The 2 steel gutters are linked together through streamlines. - The "gutters/streamlines" set makes up a stiff frame of which the length is variable according to the needs. - A wire grill is welded between the 2 gutters inner faces as well as the outside in order to set up a framework for the material which will be implemented for the finishing works of the level crossing (concrete, sand,...). - The metallic frames are protected against rust. - The frames are put in the gutters on a reinforced elastic boot and are fixed with elastomer rail clamps. Conceivable options : - According to the customers requests, an electric insulation of the 2 tracks can be considered. - The system can be planned for straight sections as well as curves. In this case, a guard rail can be intended for the faint radius curves. The guard rail is also completely separated from the metallic frame, so from the foundation through supports and elastomer washers. - The system can be implemented for different types of rails. - The gap between the rail and the gutters inner faces is filled as following : in the gutter's bottom, a small grading gravel is poured on a 80 cm height. The higher volume is filled with a suitable industrial foam. If necessary, a water harvest device at the level crossings both ends can be suggested. The both ends can be adapted to the layout of the premises. At the level crossings both ends, a protection device against the coupler is planned. Application : - The frames are put down on the bottom of tracks form. - The frames are leveled and brung into line with the track. - The set is concreted (quick setting concrete)

Request for a quoteResults for

Rail clamp - Import exportNumber of results

25 Products