- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pvd coatings

Results for

Pvd coatings - Import export

MING XIAO MANUFACTURING CO., LTD

China

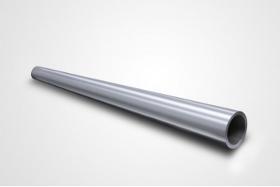

PVD Coating Turned Parts by Ming Xiao Mfg Enhance your projects with our exceptional PVD Coating Turned Parts, meticulously crafted by Ming Xiao Manufacturing in China. What is PVD Coating? PVD, or Physical Vapor Deposition, is a cutting-edge coating technique that transforms ordinary turned parts into extraordinary components. It involves the deposition of thin, durable coatings to enhance surface properties. Suitable Materials for PVD Coating Our PVD Coating Turned Parts are compatible with a wide range of materials, including stainless steel, brass, and aluminum. Ming Xiao Mfg ensures unparalleled quality in every coating application. Colors That Captivate Experience a spectrum of possibilities with our PVD coatings, available in a variety of colors. From classic metallic finishes to vibrant hues, customize your turned parts to match your vision.

Request for a quote

PLANSEE SE

Austria

Tungsten layers are components of the thin-film transistors used in TFT-LCD screens. They are used wherever large screen formats, particularly high image definition and optimized contrasts are needed. But tungsten is also used as a diffusion barrier and a conductive connector in the microelectronics industry. Using the world's largest hot rolling mill for refractory metals, Plansee is able to produce the largest tungsten sputtering target on earth. The benefit to you of large formats: The coating process is more stable and the deposited layers are of higher quality. Thanks to the special forming processes Plansee's tungsten sputtering targets have a density of almost 100 %. As a result, your process benefits from a particularly high level of conductivity and time savings due to the excellent sputtering speeds.

Request for a quote

PLANSEE SE

Austria

Plansee produces material for wear-resistant coatings, adhesive layers, decorative or DLC coatings. Offering compositions tailored for advanced hard coatings with optimized mechanical and tribological properties. Further topics that might be addressed are: enhancing of thermal and chemical stability, adding of functional properties like self-lubrication, self-hardening and self-healing. To adjust the coating characteristics to the dedicated application, Plansee offers its scientific expertise in alloying of targets and cathodes with elements that influence the coating properties as follows: Grain size and morphology, Hardness adaption, High temperature oxidation resistance, Friction coefficient, Thermal stability, Thermal conductivity, Electrical conductivity, Antibacterial properties, Color effects. Offered sputtering targets and arcing cathodes: Titanium-Aluminum Aluminum-Chromium Chromium Titanium-silicon Titanium Zirconium Tungsten carbide Titanium-diboride

Request for a quote

PLANSEE SE

Austria

Molybdenum sputtering targets are used for the manufacture of thin-film transistors used in TFT-LCD screens. Targets from Plansee are maximum dense, highly pure and show a homegenous microstructure. Therefore higher sputtering speeds, minimized particle formation during the process and homogenous layers are guaranteed. Available molybdenum alloys: MoTa, MoNb, MoNa, MoW You can choose between our single and multi-piece planar targets. Planar targets are available for all commonly used systems as well as to specific customer needs. Rotary targets are available too.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Jewelry ion spray chrome Coating machine/jewelry pvd vacuum coating equipment,pvd plating machine

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Introduction: 303 through hardened screw, has better corrosion resistance Tail annealing treatment, greatly improving the toughness of the screw CNC full grinding thread, tooth root top concentric and tooth bottom flatness high precision, can reduce the shear heat. Application: Low acid plastic + GF15 following, such as PMMA, PC and so on Temperature ≤400 ℃ Optical lenses, cosmetic packaging and so on Materials and Process: Material origin: Japan The main components: Cr, V, Mo and so on Heat treatment: vacuum quenching, hardness HRC48-52. (1020-1050 vacuum quenching, high temperature tempering 550-570 more than three times, the rear high temperature annealing softening treatment) Surface treatment: PVD coating (TiN, TiCN, TiAlTiN)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China CNC Turning Factory, Custom hose nozzles from stainless steel, carbon steel with zinc plated, chromed, PVD coating, aluminum alloy, brass.

Request for a quote

ITALGEAR SRL

Italy

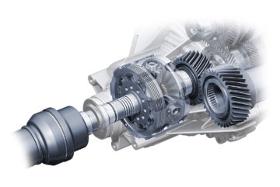

Cylindrical ground gears are cut by hobbing machines of the latest generation and finished by Reischauer and Gleason CNC grinding machines equipped with automatic loaders and special software that allow the correction of the twisting errors that may occur in helical gear and, with special ground cycles strategy minimizing noise of gears in operation. ITALGEAR can also make the finishing of the gears after carburizing heat treatment adopting the Skiving technology, which allows the precise finishing of gears through superfinishing of the teeth with a hard metal PVD coated hobs. The technology allows production of groundquality precise gears while reducing cutting time and costs effective at the same time. On request, ITALGEAR engineers can team up with the Customer R&D and suggest any appropriate measures to optimize the gear meshing in order to obtain low noise in operation.

Request for a quote

ITALGEAR SRL

Italy

The common roots shared with the Poppi Forging Industries provide ITALGEAR a facilitated access to the forging facilities of the Group and particularly the ability to source electrical upsetted parts with dimensions that are predetermined by specific software’s that allow minimizing the stock material hence resulting into superior quality and price effectiveness of the finished product. Gears of shafts and axle shafts, after their heat treatment, can also be finished with the use of the Skiving technology that makes use of specific hard metal hobbing tools that are PVD coated. The Skiving technology allows production of gears that combine a high quality finishing with reduced machining time and costs.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Precision CNC milling parts Precision CNC milling parts Material aluminum, Stainless steel, (https//www.frimaparts.com/precisionmachiningstainlesssteelshaft/) brass ,plastic, carbon steel, nylon, PP Dimensions according to customer’s drawing Surface treatment Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing PE bag, carton, wooden box Precision CNC milling parts Service project To provide production design, production and technical service, mould development and processing, etc. Testing machine Digital Height Gauge,

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

IMETA SRL

Italy

PVD coating is commonly used on seaming chucks made of steel.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

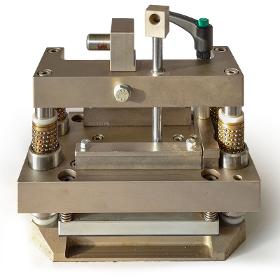

Metzner provides a number of proven automation solutions for the automatic loading and unloading of coating carriers for CVD and PVD coatings. The abbreviations PVD (Physical Vapour Deposition) and CVD (Chemical Vapour Deposition) stand for different coating processes. When loading the PVD spears, we differentiate between "single-loading" and "back-to-back loading". In addition to part loading, spacers are loaded onto the spears in addition to the parts. In single-loading, a spacer is located behind each individual insert, whereas in back-to-back-loading, two inserts are placed "back to back" and only then is a spacer loaded. To implement "back-to-back-loading", a turning station is integrated into the machinery. This station is used to turn the corresponding insert by 180 degrees, loading it directly onto the respective spear.

Request for a quote

MERCEL, CUTTING KNIVES S.R.O.

Czech Rep.

We produce special cutting tools for cutting credit cards and cards of a similar shape and their assembly, on paper, but also on sheets. Our dies are used, for example, in the manufacture of medicines. Custom production of special knives and assemblies Based on our customers' suggestions, we often develop and produce special cutting tools. We will also produce entire tools according to the submitted drawing documentation. Service and reconstruction of special tools In the case of cutting assemblies, we cut individual parts or perform complete reconstructions, including the production of new parts. Surface finish Special coatings are applied to the knife to extend the lifespan. Surface thickness 2-6 µm. PVD-VARIANTIC alternative Duplex (PVD coating + nitriding)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

SLADE OAK LTD

United Kingdom

A unique alternative to traditional cocktail glasses, this Straight Copper Mug is perfect for presenting on-trend cocktails and beverages. With a vintage copper PVD coating and stainless steel construction, this copper cup is ideal for commercial or domestic use and is highly resistant to staining.

SLADE OAK LTD

United Kingdom

A unique alternative to traditional cocktail glasses, this Straight Copper Mug is perfect for presenting on-trend cocktails and beverages. With a vintage copper PVD coating and stainless steel construction, this copper cup is ideal for commercial or domestic use and is highly resistant to staining.

Results for

Pvd coatings - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Coating machinery (3)

- Cutting - machine tools (3)

- SMALL METAL PARTS (3)

- Steels and metals - surface treatment and coating (3)

- Gears (2)

- Blades and knives, industrial (1)

- Ceramics, industrial (1)

- Hand tools, non-power (1)

- Handicraft (1)

- Houseware, copper (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Milling - steels and metals (1)

- Nozzles - non-ferrous metal (1)

- Screws (1)