- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punching lasers

Results for

Punching lasers - Import export

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR Stainless steel: SS304, SS316 Aluminum alloy Process: Flame/plasma/laser cutting Punching/bending CO2 welding Machining Application: Agricultural & farm machinery Off-shore industry Construction equipment General machinery

Request for a quote

BS STEELWORKS GMBH

Germany

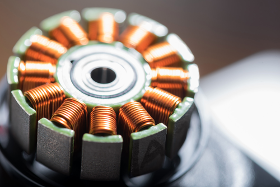

Non-Grain Oriented Electrical Steel (NKO) is a specially manufactured steel to achieve certain magnetic properties. It ensures low power loss, core loss and high permeability. NGO is the first choice for manufacturing lamination stacks for stator and rotor of electric motors. The sheets are laminated and cut into the final shape through various processes before winding. Punching, laser cutting and wire EDM are some of the processes used to achieve the final shape.

Request for a quote

ALUMAX

Greece

Alumax, also, offers final parts of a high quality level in competitive prices. We produce medium and even small batch size components, at short lead times, using our customer’s own drawings or samples. For this purpose, we have invested in modern machinery, such as CNC milling machines, sawing centers and punching & drilling center. Sawing Drilling Milling (from small parts up to 6m bars) Turning (up to a diameter 250mm and a length 800mm) Laser cutting Shearing Forming Punching Laser engraving The above processes, if appropriate, are followed by joining the parts together or with glass, plastic, etc., by welding, bolting, riveting or binding with adhesives.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Fabrication & Stamping services more than 20 years,have been customized many kinds of sheet metal Casing,Enclosure,Bracket,Plate,Decoration Panel for different industries. We providing various processes such as punch Laser cutting,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Sheet Metal Fabrication Products Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishes: Anodize,painting,powder coating,blackening,electroplating of chrome/zinc/nickel /tin/silver... sales@mxmparts.com +86 13780014913

Request for a quote

LVD

Belgium

Combination technology offers complete part processing for flexible manufacturing. The punch press handles high-speed punching and forming operations. The fiber laser delivers high-quality cutting of outer contours, intricate inner contours and can be used for material etching. Choose from single-head (Strippit PX-L) or turret style (Strippit V/VT-L), 200 or 300 kN configurations, 3- or 4-kW fiber laser in a modern, energy-efficient machine design from the industry’s punch-laser technology pioneer. KEY FEATURES 20 direct-drive indexable tool stations (Strippit PX-L) 40/48 turret stations (Strippit V/VT-L) Fully programmable punching cycles (Strippit PX-L) High-speed punching, forming, bending and tapping Laser cutting of unique shaped holes or contours, material etching Fanuc 3- or 4-kW fiber laser Precitec ProCutter auto-focus cutting head Next-generation rack and pinion drive system eliminates backlash, provides accurate positioning

Request for a quote

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quote

KAS METAL ELEKTRONIK

Turkey

Perforations drilled side by side at equal intervals and equal width Can be manufactured to the desired extent with laser and punch machines Perforation with hexagonal patterns provides an optimal air flow through the cabinet The diameter of hexagonal holes can be 6, 7, 9 mm A hole with diameters 6 and 9 has a 1 mm distance between the holes A hole with diameter 7 has a 2 mm distance between the holes Standardized products Installable on front and rear of the cabinet, the rear door is equipped with hinge and lockers Available in stocks There are two types of doors: - Convex type (from 9U to 47U varieties with 63% -77% -80% discharge) - Straight type (from 9U to 47U varieties with 63% -77% -80% discharge)

Request for a quote

FOXLASER

Bulgaria

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

With a versatile punch/ laser combination service, Alpha are able to offer complete flexibility to produce punch details such as louvres and ribs alongside complex lasered profiles and etches in one process. The benefits of Punch/ Laser combination are that production time is dramatically reduced by combining the two processes. Costs savings are also made as complex and costly tooling is not required.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The MCSB/2B-900 is a 900mm wide belt and brush/roll dry working Grindingmaster that is equipped with powerful motors allowing it to process the toughest and heaviest jobs around. R.P.M.1500 Hp/Kw15 + 7.5 kW Typical process applications covered by this machine: Stock removal of multiple individual parts and sheet materials Grain and scratch brush finishing of any material. Sizing and finishing of parts and sheet materials Deburring punched, nibbled, sheared or laser-cut sheet metal parts. Calibrating or keying carbon, rubber, wood or other soft materials.

Request for a quote

A + H THOMAS GMBH + CO. KG

Germany

We manufacture your product for you with our modern screen printing machines and our expertise. In the subsequent print finishing, your product is punched, lasered or cut as required. The advantages at a glance: almost all materials can be printed UV-resistant, weather-resistant, water and abrasion resistant applicable for all color systems (such as RAL, HKS, NCS, Pantone) Special and effect colors according to customer requirements lasting durability Self-adhesive front panel in screen-printed quality with translucent windows, various cut-outs and raised keys

Request for a quote

METALUX

North Macedonia

LASER CUTTING Our laser cutting services provides the ability to create custom parts out of a variety of materials. Our Fiber Laser Machines can cut almost anything you can draw, including sharp angles, smooth curves, small screw holes and complex trim patterns and lace designs. CNC PUNCHING All of our products are made using cnc punching machines. Which enable precision manufacturing. We offer this service also to third parties. BENDING We have multiple bending presses, which enables us to produce a large quantity of standardized parts and to offer quick turn around time for our clients. We can bend complicated shapes, different material thicknesses and types. WELDING We offer different type of precision welding. Like TIG, MIG and Spot welding. POWDER COATING Powder Coating gives consumers, businesses, and industries one of the most economical, longest lasting, and most color-durable quality finishes available on virtually any type of meta

Request for a quoteResults for

Punching lasers - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Industrial sheet metal work (3)

- Steel (2)

- Doors, industrial (1)

- Finished Metal Products (1)

- Grinding - steels and metals (1)

- Laser - cutting and welding machines (1)

- Planing lathes, automatic (1)

- Punching machine tools (1)

- Screen printing for advertising (1)

- Steel & Metals (1)

- Steels and metals - welding and brazing (1)

- Turbine drilling services (1)