- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punch bending tools

Results for

Punch bending tools - Import export

METAL IN LTD

Bulgaria

Metal In has 9 eccentric presses with a force of 40 to 200 tons. We have loaders for roll operation and feeders. 3 hydraulic presses with a force of up to 160 tons. We produce press parts for the automotive, construction and furniture industries. Metal In is certified according to IATF 16949: 2016. We have a tool section for the production and maintenance of punches and bending tools. We also offer a subsequent operation of zinc and zinc-nickel.

Request for a quote

AHP PLASTIK MAKINA

Turkey

A key attribute of plastic is its resistance to environmental stress cracking. It can be tested easily with AHP ESCR tester. According to ASTM D 1693 , digital timer , PID temperature controller, water circulation system, bending tool, brass sample holder , glass tube , sample cutting punch , sample notch press , sample bending tool

Request for a quote

AHP PLASTIK MAKINA

Turkey

A key attribute of plastic is its resistance to environmental stress cracking. It can be tested easily with AHP ESCR tester. According to ASTM D 1693 , digital timer , PID temperature controller, water circulation system, bending tool, brass sample holder , glass tube , sample cutting punch , sample notch press , sample bending tool

Request for a quote

METAL IN LTD

Bulgaria

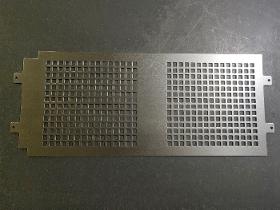

Metal In Ltd have two punching machines – TRUMPH and Raskin and two CNC bending machines TRUMPH. This allow us to produce punching details with maximum sizes 1250x2500 mm and maximum thickness 4 mm. Machines are with maximum length 3000 mm and power 120 tones. We also have eccentric presss machines with maximum power of kick 160 tones and hydraulic presses with maximum power 100 tones. We have our own production of punching and bending instruments. The company have three roller bending machines for sheet iron, profiles and tubes. Except upper mentioned operations we also make MIG-MAG and WIG welding, cleaning and powder coating.

Request for a quote

MICRON AMERICA

Turkey

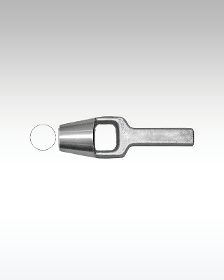

Polished barrel with hardened cutting edge. Hole tapers inside for easy punching clearings. Available in 2 sizes. These punches should be used on an Micron Cutting Board.. The use of an Micron wooden mallet or rawhide hammer is recommended. Steel hammers are not recommended.

Request for a quote

MICRON AMERICA

Turkey

It has been designed and constructed with respect to the pre punch holes to prepare a connecting element assembly, especially for metal plates. These packages are produced in order to order and delivery for approximately 3 4 weeks.

Request for a quote

MICRON AMERICA

Turkey

Micron hand tools are made of high quality stainless steel material. Remember to use a plastic mallet, not a steel hammer.

Request for a quote

MICRON AMERICA

Turkey

The frame is made of highly polished steel and the cutting dies are simply pushed in for easy replacement. Replacement cutting tubes are also available.

Request for a quote

MICRON AMERICA

Turkey

Kit contains the most frequently used sizes packed in a sturdy vinyl pouch. These punches should be used on an Micron Cutting Board.. The use of an Micron wooden mallet or rawhide hammer is recommended. Steel hammers are not recommended.

Request for a quote

MICRON AMERICA

Turkey

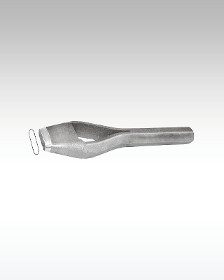

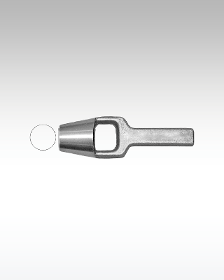

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards

Request for a quote

METAL-TECH

Poland

DIE FOR A PELLET MACHINE, MAKING DIES AND ROLLS CUSTOM

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal punching for all kinds of materials. We work on AMADA machines. Max width: 3000mm Max thickness: 6mm

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The UBM 6-20 M is a universal bending device for steel pipes up to 20 mm OD. It comes with a set of bending rolls for common applications. An integrated scale for angle detection helps you to reach the required pipe dimension in only one work step. The telescopic lever keeps the operator’s forces low when bending rigid pipes. •Compact design •Compact for mobile usage •Standard with a set of 6 bendings rolls •User friendly •Easy handling •Simple adjustment •Wide workpiece range •Innovative design •Angle scale included •Telescopic lever

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NITTO KOHKI EUROPE GMBH

Germany

New design adopted for punching stainless steel. Inching function as standard. 25mm and 26mm dia. holes are possible with optional parts.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

HTMACH Turret Punch Press Machine is capable of working large sheet metals with fast axes speed and stroke frequency. It is used high level mechanic and electronic automation equipments in its construction. Machine keeps its compact structure with all its specialties and equipment. All of the components on the machine are world wide known brand names. Capacity is 1225mmX30ton

CNC KOVINE GORSEK

Slovenia

A complex 5 axis tooling part for the Auto Industry (Ferrari)

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Hammerle, Durma, EHT, Finn-Power, Jordi, Gizelis, LVD, Trumpf, Prima Power, RICO PRCN, Safan-Darley, STR, Ursviken etc. We supply solid pieces 100, 200, 300, 500 mm; section set (cutted) 550 mm and complete sets for the full length of your press brake according to the customized pieces or the same as original tooling. For TRUMPF-WILA press brake tools we can offer 100% compatible tools as original. Dies could be used with Beyeler-Bystronic system. Any punches for Trumpf-Wila with low weight could be equipped with push buttons for quick frontal extraction. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Accurl, Adira, AM Machinery, Amada, Augusta, Axial, Baykal, Boschert, Bystronic, CMU, CoastOne, Colgar, Colly, Gasparini, Gilardi, Gizelis, Guifil, Dener Makina, Deratech, Durma, Edward Pearson, Ermaksan, Euromac, Femas, Fratelli Farina, GADE, Gasparini, Gecko, HACO (Atlantic), Hammerle, Hesse, Hezinger, Hilalsan, IMAL, Inanlar, Ironmac, ITEK, Jean Perrot, Jordi, KAAST, Karmet, Kingsland, Knuth, LAG, Mecos, MVD, Muratec, Nargesa, OMAG, Peliant, Rico, Salvagnini, Schiavi, SMD, STR, Tabama, TCI etc. We supply solid pieces 415, 835 mm; section set (cutted) 805 mm and complete sets for the full length of your press brake. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

FOXLASER

Bulgaria

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

BOGRAMA AG

Switzerland

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

PRECITOOLS SRLS

Italy

We offer special adjustable bending dies for various press brakes with medium and high tonnage for bending of big thickness sheet metal. These dies are great solution for the possibility to replace several set of standard dies and adjust die opening directly on the machine. Models available: V25-125; V65-180; V120-300; V150-400. In addition there are options of semi-automatic and automatic adjustment system. We are able to study the project for the possibility to offer together with adjustable dies all necessary punches as complete solution.

Request for a quoteResults for

Punch bending tools - Import exportNumber of results

32 ProductsCompany type