- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pump control

Results for

Pump control - Import export

BELGOMILK IA SA

Greece

Total width 600mm Total length 500mm Guides latéraux réglables en acier inoxydable, Central Operation Panel, start – stop – emergence Central Operation Panel, start – stop – emergence Capability for dosage adjustment up to 10 liters Oil storage tank and float controlled transfer pump with ballcock Connection with the factory CIP

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTreat-R preparation and feeding system ensures an even and reliable product supply. At the same time, the medium is optimally prepared for the production process by stirring and circulating. The use of the VRP dispenser series for the further transport of the medium offers the following advantages: optimal processing of viscosities up to 50,000 mPas very low shear stress of the medium very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - no air supply necessary - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - Stator material is adapted to the medium to be pumped Application: - Feeding and processing of medium to highly sensitive media, e.g.: Silicones, adhesives, resins, greases, colour pastes, metal-filled pastes

Request for a quote

LUTZ PUMPEN GMBH

Germany

The compact MEMDOS SMART LK stepper motor pump combines the size advantages of a solenoid diaphragm dosing pump with the precision of a motorised diaphragm dosing pump. This versatile pump is available in five different performance ranges, making it suitable for a wide range of industrial applications. The fully variable drive of the MEMDOS SMART LK enables infinitely variable adjustment of the stroke frequency, ensuring precise control of the dosing performance. An outstanding feature of the MEMDOS SMART LK is the ability to reduce the suction speed in two stages. This function makes dosing viscous media considerably easier and increases the precision of the dosing.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-D bin emptying system offers a modern way of emptying small containers and bins cleanly. The use of our dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 100 ml to 5 l - viscosities of approx. 80,000 - 1,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of filler-loaded material - no backflow within the withdrawal pump - electrical control of the pump with pressure control - direct dosing from the container possible - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, fats, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes)

Request for a quote

LUTZ PUMPEN GMBH

Germany

Electronic piston dosing pump FEDOS DX The microprocessor-controlled FEDOS DX combines the proven features of the FEDOS series with the latest requirements in dosing technology. Ideal for applications that require integration of the pump into control systems or control loops, the FEDOS DX offers versatile adaptation to various control signals and system monitoring. Main features: Performance range: 0.17 to 31.5 l/h, up to 100 bar Flexibility: Adjustment of the stroke frequency by division or multiplication Precision: Suitable for precise mixing tasks Independence: Low dependence on back pressure Efficiency: Linear change in dosing quantity with the stroke length Ease of use: Plunger drive with easy-to-operate power adjustment Optional: Rinsing lantern The FEDOS DX is the ideal choice for precise dosing applications that require high accuracy and adaptability.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MEMDOS LB solenoid-driven diaphragm dosing pump is the ideal solution for applications where the pump needs to be integrated into control systems or control loops. Thanks to its robust plunger drive and the option of manual or automatic capacity adjustment, the MEMDOS LB reliably and precisely doses various media such as acids, alkalis, precipitants and flocculants. The dosing capacity is adjusted either by mechanically adjusting the stroke length or by controlling the speed of the three-phase motor via a separate frequency converter. This flexibility enables precise control of the flow rate to meet different requirements. On request, the MEMDOS LB is also available with a double diaphragm system, which offers additional safety and reliability. This combination of versatile control and robust design makes the MEMDOS LB the ideal choice for demanding dosing tasks.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This feeder consists of a completely overhauled rotary feeder from CMC, a new pressure/vacuum pump made by Becker, and a self-programmed control system. All components are mounted on a stable frame made of aluminum construction profiles, which can be placed as a compact unit autonomously at any desired position in the production. The machine can either be operated continuously or controlled by an external signal. This allows inserts to be placed with pinpoint accuracy in a collecting section or at high speed on a conveyor belt to be addressed via inkjet, for example. We offer a 6-month warranty on parts and service for this machine. Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

the economical alternative Replacement for STRATE 1DF2 and 2DF2 pump controllers suitable for connection to all STRATE fill level recording systems: contact-based or contactless the 2DF2 plus also handles dual level measurement: Sensor/pilot tube and sensor/contactor for outstanding operational reliability the current level and operating hours are always shown on the display

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Redundant twin measuring system where there is a requirement for increased operational safety for sewage pumping stations (e.g. main pumping station) for municipal applications. Product features The twin measuring system HWAS-BN uses two mutually independent measuring systems which work in different ways. The analogue sensor HWAS for integration in the pump control unit is combined with the pneumatic-mechanical contact sensor system MB. If one of the two measuring systems fails, emergency control is automatically triggered by the other measuring system.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Redundant twin measuring system where there is a requirement for increased operational safety for sewage pumping stations (e.g. main pumping station) in building service engineering and for municipal applications. Product features The twin measuring system MWAS-BN uses two mutually independent measuring systems which work in different ways. The analogue sensor AS for integration in the pump control unit is combined with the pneumatic-mechanical contact sensor system MB. If one of the two measuring systems fails, emergency control is automatically triggered by the other measuring system.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

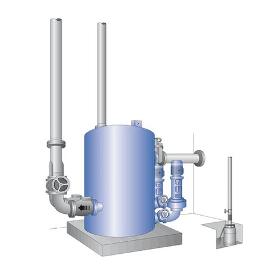

With our trusted separator system, suitable for up to 29,000 residents at a system power of 600 m3/h. The base version, the AWALIFT 9/4, achieves a discharge head of 40 mWS, and the expanded version AWALIFT 9/4x2 achieves 80 mWS. Smart pump controllers are available as accessories, and are specially adapted to your system and your specific needs. The impellers are adapted to the operating point to achieve optimal performance. Draining towns with up to about 29,000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with four separator systems Four centrifugal pumps and motors according to type and operating location required Eight pump gate valves Four STRATE non-return valves One Y-pipe DN 300 Four pressure pipe gate

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 6/2 is designed for up to 9,300 residents, and is able to provide drainage for small towns. The proven separator system is also used in this size, and the systems are installed dry. System operation and maintenance are very user-friendly. The pump controls are designed according to the user's needs and mounted in an external cabinet. Additional accessories are available for this system, please submit your inquiry. Draining towns with up to about 9300 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 200

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

This sewage pumping system can be used for districts with up to 3700 residents and it offers a discharge head of up to 80 mWS. The expanded version, the AWALIFT 3/2x2, even offers a discharge head of up to 120 mWS. Accessories, such as a smart pump controller, a basement drainage pump, pipelines and a variety of flanges within a single building, and much more are available for purchase on request. Draining small towns with up to about 3700 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 125 Two pressure pipe gate valves DN 125

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 2/2x2 wastewater pumping system is suitable for towns with up to approx. 2800 residents. The system can achieve a discharge head of up to 120 mWS, thanks to the parallel operation of two pumps. An adapted, intelligent pump controller handles control, ensuring almost fault-free operation. Draining small towns with up to about 2800 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems 2 x 2 centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 100 Two pressure pipe gate valves DN 100 Level measurement

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 74/1 is used primarily for draining floors, multi-family buildings and properties above the backflow level in accordance with DIN 1986-100, e.g. for properties that cannot be drained via a natural slope. DIN EN12056-4 establishes the upper edge of the street at the connection point to the public sewer system as the backflow level. Two-family homes Facilities that cannot be drained using natural gradient As protection from backwater damage Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 100 is the system preferred for draining storeys, houses and plots of land below the backwater level in accordance with DIN 1986-100, i.e. for properties that cannot be drained using natural gradient. DIN EN 12056-4 specifies the backwater level here as being the road surface of the connection point to the public sewage system. Single-family homes (e.g. toilet, shower, bath, sink, washing machine) Basement flat Party rooms in the basement Two-family homes Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

An especially large system with six pumps and a tank content of 26.0 m3, a system power of 800 m3/h and a weight of approx. 6.3 t can reliably handle drainage for a city with up to 37,000 residents. The unique pump controls achieve a discharge head of 40 mWS, while the AWALIFT 10/6x2 version boosts this discharge head to 80 mWS. Proven components, such as our separator, separating flaps, level controller, etc. are used in this system as well. Draining towns with up to about 37,000 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with six separator systems Six centrifugal pumps and motors according to type and operating location required Twelve pump gate valves Six STRATE non-return valves One Y-pipe DN 300

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Magnetic-inductive flow measurement allows the precise measurement of electrically conductive liquids such as sewage. Standard measuring values are the current flow and the accumulated pumping capacity (e.g. daily volume). The measuring signals are available either as 4 – 20 mA or impulse signals and can be transmitted to the data recorder for state recording and diagnosis or to the AWAcontrol control technology for pump control. Magnetic-inductive flow meters are reliable and economic compact units or installation in the pressure line and are available in two basic versions: Sensors for pipe installation with integrated measuring transducer and on-site display as a compact unit Sensors for pipe installation with separate measuring transducer. With this version, the measuring transducer can be located separately on the wall in the service building or as a fitted housing directly in the AWAcontrol control cabinet.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Compact control systems with micro-processor technology for controlling STRATE sewage pumping stations with two pumps each and an installed motor rating of up to 5,5 kW per pump. Particularly suitable for building services engineering (twin systems) and do not require a separate control cabinet. Compact control system AWAmaster 2 in plastic housing Ready for connection with 1.5 m cable and CEE plug 16 A, 5-pole Parallel operation of both pumps to cope with increased sewage volume (e.g. during heavy rain) LCD plain text display Thermal and electrical monitoring of the motors Manual – 0 – Automatic functions Pump switch-off through switch-off point with run-on time Acknowledgement button Electronic monitoring of the motor current Forced switch-on, switchover and alternation of pumps Variable graduated start-up (switch-on delay) Internal acoustic alarm Collective fault message potential-free and potential-bound Backwater alarm potential-free

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The compact control system with micro-processor technology for controlling STRATE sewage pumping stations with one pump and an installed motor rating of up to 5,5 kW. Particularly suitable for building services engineering (single systems) and do not require a separate control cabinet. Compact control system AWAmaster 1 in plastic housing Ready for connection with 1.5 m cable and CEE plug 16 A, 5-pole LCD plain text display Thermal and electrical monitoring of the motor Manual – 0 – Automatic function Pump switch-off through time or switch-off point Acknowledgement button Operating hours counter Ammeter Electronic monitoring of the motor current Forced pump switch-on Variable graduated start-up (switch-on delay) Internal acoustic alarm Collective fault message potential-free and potential-bound Flood alarm potential-free All settings and fault messages retained after power failure (battery back-up not required) Reserve inputs for float switch, telecontrol module

Request for a quote

TROTEC GMBH

Germany

When it comes to applications such as fog production, the very powerful turbine in this product series and FS200 fluid pump can be adjusted continuously, being adapted more precisely to individual operating conditions. The item is known for its low fluid consumption, as well as the maximum 100ml per minute. The item is continuously controllable, with reduced dimensions compared to its predecessor. The 40% smaller space-saving solution comes with foldable canister, being extra dense with smoke because of the controllable fluid pump. The item is easily portable because of the narrow passage like a safety ladder, while the intelligent energy coupling of heating, pomp and turbine is also possible, ensuring a constant thick fog, without any reheating induced disruption. FS200 - the technical data: Fog time at max. level: approx. 210 s Fog time at medium level and below: permanent fog Compressor performance: 1,500 W Fan turbine performance: 1,600 W

Request for a quote

PERAQUA PROFESSIONAL WATER PRODUCTS GMBH

Austria

Stainless Steel, also available in non corrosive plastic housing, Inverter heat pumps are equipped with variable speed compressors, depending on the energy demand and the surroundings conditions, higher efficiencies at much lower sound pressures, 65% higher C.O.P as for common on and off heat pump, Modbus capable, touch control with integrated WLAN connection for control via mobile device, titan heat exchanger, R32 defrosting liquid

Request for a quote

KAMAT GMBH & CO. KG

Germany

Multi-consumer valves distribute the output of the high-pressure pump evenly or as required to several high-pressure blasting tools. KAMAT offers two valves for this purpose: the mobile dual consumer control and the MVS4 multi-consumer control. When the consumer is opened, both controls open the valve and when the consumer is closed, the valve is closed. When all valves are closed, the controls switch off the pressure generation. The dual-user control is used to control one or two high-pressure consumers, such as high-pressure guns. The dual-user control is available with pneumatically or electrically controlled valves. The consumer and the high-pressure plunger pump have a corresponding control option. The dual consumer control and the consumer are connected by an electrical switch.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT foot valves and foot switches are products of the highest technical quality. They are designed for opening and closing the water supply to high pressure blasting equipment. This valve can be used to open and close the water supply to a high pressure blasting unit. The water is supplied by a high pressure hose connected to the foot valve. When the pedal of the valve is depressed, the valve opens. When the pedal is released, the valve closes and the water is discharged through the bypass without pressure. The foot valve and high pressure pump can also be connected via an electrical switch. If the pump has a suitable control, the pressure generation is switched on or off mechanically when the valve is actuated. The KAMAT foot valve has been designed and constructed in accordance with the rules of technology and applicable standards and guidelines.

Request for a quote

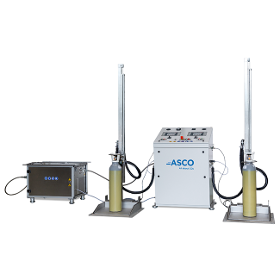

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quoteFAUDI GMBH

Germany

Advantages The multiple options enable us to fulfill special customer requests in a flexible way. FAUDI Belt Filters have the ability to be installed on existing vessels or can be delivered as complete systems with vessels, pumps, heating, cooling and control systems. Furthermore, the system enables an increased flow rate. Area of application For the continuous cleaning of coolants, especially emulsions and oils of machine tools and cold rolling mills. For the filtration of liquids with a high demand on purity. The impurities may vary in size, shape and material. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil, emulsion and water Filter material filter belt

Request for a quoteResults for

Pump control - Import exportNumber of results

155 ProductsCountries

Company type

Category

- Pumps (41)

- Water - production and distribution (8)

- Dosing pumps (5)

- Laser printing (4)

- Measurement - Equipment & Instruments (4)

- Agriculture - Machines & Equipment (3)

- Construction machinery (3)

- Control boxes - electric (3)

- Energy - renewable (3)

- Automation - systems and equipment (2)

- Cleaning and maintenance - equipment and supplies (2)

- Gear pumps (2)

- Heat pumps, industrial (2)

- Hydraulic equipment (2)

- Industrial valves, operating equipment (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Medical electronics - apparatus and equipment (2)

- Textile dyeing - machinery and equipment (2)

- Valves for industrial fittings (2)

- Agricultural machines and accessories (1)