- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- prototype manufacturing

Results for

Prototype manufacturing - Import export

ACTIVETOOL UNIPESSOAL

Portugal

Prototype manufacturing services for new product development and testing.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

The first formation of the Turkish Defense Industry in History dates back to the 14th century. Our Defense Industry, which was in a strong position until the 17th century, lost its power after the 1st World War and we were left out of the developments in Europe in the 18th century. II. The activities in the field of defense industry, which started in the first years of the Republic period after the World War II, became foreign-dependent with the aid received from the USA due to the economic situation and political reasons. Concrete steps were taken to establish the National Defense Industry in the 1970s. With the development plans initiated in the 1980s and the establishment of the Undersecretariat of Defense Industry, necessary steps were taken to nationalize the weapons and equipment used. Our national defense industry has mobilized many sectors in parallel with the recent developments. One of the most important of these is the injection mold industry.

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for CNC prototypes with a ranges for CNC machines

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

TAIHAN FIBEROPTICS

South Korea

# Description Taihan Fiberoptics offers an extensive selection of self-supporting fiber optic cables used in pole-to-pole networks, overhead transmission lines and distribution lines as an excellent solution for aerial networks with outstanding optical performance,durability and reliability. All our prototypes are designed and manufactured to operate under the required environmental conditions and to endure the external forces, such as wind, ice and extreme temperatures to which they might be exposed to during their lifetime. ADSS cables have become the No.1 choice for ISPs and Power Utilities for network expansion due to its faster deployment and reduced installation cost. # Applications - Pole to Pole aerial installations - FTTx networks - Enterprise OSP Networks - Electric Utility Distribution Power Lines - Duct installations # Products - Rock ADSS™ Short span - Rock ADSS™ Long span

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECISION CERAMICS

United Kingdom

Macor Machinable Glass Ceramic is one of the most versatile and unique technical ceramics available and as you would expect from Corning’s principal, longest serving and highly-respected UK distributor, Precision Ceramics offers a complete, fast turnaround, research and development, design, prototyping and manufacturing service which is second to none! We’re also experts in Macor Machining and Metallization.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Design Gear – The customised special gearbox For everyone who expects more: special gearboxes from the specialist. We provide gear solutions for your individual performance requirements, including designs, tooth developments, prototype manufacture, extensive tests and documentation, right up to the delivery of the series. Our customised gears include: Single-stage bevel gears as control or reverse gears Labyrinth-sealed gears with a degree of efficiency of > 98% High temperature gears for ambient temperatures of up to 300°C Saw drive gears Test station gears with output speeds of up to 12000 min -1 Double gears with two transmission ratios Robotic gears Spur gears High precision gears And much more

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

For everyone who expects more: special gearboxes from the specialist. We provide gear solutions for your individual performance requirements, including designs, tooth developments, prototype manufacture, extensive tests and documentation, right up to the delivery of the series. Our customised gears include: Single-stage bevel gears as control or reverse gears Labyrinth-sealed gears with a degree of efficiency of > 98% High temperature gears for ambient temperatures of up to 300°C Saw drive gears Test station gears with output speeds of up to 12000 min -1 Double gears with two transmission ratios Robotic gears Spur gears High precision gears And much more

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover EWOQE's comprehensive service offering in 3D printing for mechanical components and prototype construction! We provide a variety of advanced 3D printing techniques such as FDM, SLS, MJF, and SLA to meet your needs and produce high-precision components. Our experienced team assists in the development and manufacturing of prototypes as well as functional mechanical parts. Understanding the importance of quick iterations, we offer rapid turnaround times to shorten your development cycles and optimize your time-to-market. With our advanced 3D printing technologies, we can achieve complex geometries and fine details to ensure your components meet the highest quality standards. Whether you require prototypes for product development, individual pieces for specific applications, or series production, we have the solution for you. Depend on EWOQE as your trusted partner in 3D printing for mechanical components and prototype construction.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your expert for prototype construction in precision mechanics! We offer a comprehensive range of services to meet your demanding requirements. Utilizing advanced 3D printing techniques such as FDM, SLS, MJF, and SLA, we deliver high-precision plastic components quickly and cost-efficiently. Our dedicated team is here to assist you with the design and manufacturing of prototypes, no matter their size or the quantity required. We understand the critical importance of quality and precision in precision mechanics and are committed to exceeding your expectations. Thanks to our additive manufacturing technologies, we can produce complex components with high accuracy, aiding you in efficiently achieving your development goals. Our express service also ensures fast turnaround times to optimize your time-to-market. Depend on EWOQE as your reliable partner for prototype construction in precision mechanics.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your reliable partner for the prototype construction of enclosures. Offering a wide range of 3D printing processes such as FDM, SLS, MJF, and SLA, we provide fast and cost-efficient solutions tailored to your requirements. Our experienced team is dedicated to supporting you in the design and manufacturing of enclosure prototypes, no matter their size or quantity. We understand the critical importance of quality and functionality for enclosures in the industry and deliver high-precision components that meet your specifications. Leveraging our additive manufacturing technologies, we can produce complex enclosures with high accuracy and attention to detail. Our express service enables us to swiftly handle even the most urgent projects, optimizing your time-to-market and ensuring your ventures progress efficiently. Trust EWOQE as your trusted partner for enclosure prototype construction.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the diverse services EWOQE offers for the industry! As a leading B2B partner at the highest level, we utilize 3D printing to revolutionize traditional manufacturing processes. Our expertise ranges from creating 3D models to manufacturing prototypes and small series, all the way to producing final products. Benefit from our knowledge in additive manufacturing and join us in creating innovative products. Whether you need high-quality plastic parts, assistance with design and model making, or customized solutions, we are your reliable partner. Thanks to our modern machinery and years of experience, we consistently deliver high-quality results. Trust EWOQE for your specific requirements in additive manufacturing and contact us today to advance your projects. Our commitment to fast, cost-efficient services and our ability to handle complex design and construction challenges make us an ideal choice for businesses looking to leverage the advantages of 3D printing technology.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the world of Additive Manufacturing with EWOQE! As a leading B2B partner at the pinnacle of industrial standards, we utilize 3D printing to revolutionize traditional manufacturing methods. Our focus is on producing components with precision and efficiency, not to replace existing production processes but to enhance them. We are convinced of the diverse possibilities that 3D printing offers and view it as an indispensable tool for achieving our goals. Through continuous investments in research and development, we remain at the cutting edge of this technology, always offering our clients innovative solutions. Our range of services includes the creation of 3D models, the manufacturing of prototypes and small series, as well as the production of final products. From high-quality plastic parts to design and model making, we are your reliable partner for all your Additive Manufacturing needs.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

From the Idea to Prototyping to Series Production and Evolution – MicroControl plans, develops and manufactures individual solutions. MicroControl experts will work in close liaison with the customer to realize hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually.

Request for a quote

ARINKO BAUTZEN GMBH

Germany

Custom sheet metal systems from the first design draft to the finished product – adapted specifically to customer requirements: In a first step, the wishes of the customer are converted using our design ideas and practical expertise into a convincing and production-ready design. The constructive implementation of the design draft, as well as all other specifications and conditions, tailored to the special technological opportunities of the respective production partner, are the focus of the second project phase. The next step of this process is the manufacture of the prototype, such as the machine housing, which is performed at the production partner's site – from the laser cutting to the finished painted assembly unit. In order to present the product in the quality you expect, our designers coordinate all interfaces on site throughout the entire process down to the final assembly to present errors and to save time.

Request for a quote

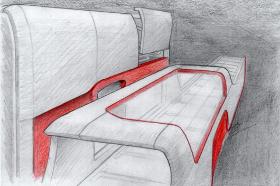

EWOQE GMBH & CO. KG

Germany

At EWOQE, we offer top-tier services in model making for design, testing and development, as well as prototype construction through advanced 3D printing. Our highly skilled engineers assist you in designing and manufacturing prototypes that perfectly meet your requirements. Utilizing additive manufacturing technologies and high-quality plastics, we produce high-precision components quickly and cost-effectively. Our processes are designed to enable accelerated product development and optimize your time-to-market. Whether you need prototypes for new product designs, functional components for testing, or models for design purposes, we have the solution for you. Rely on our expertise in 3D printing and plastic processing to meet your requirements and successfully implement your projects.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

If companies want to decide on a future-proof bus technology, comprehensive advice will be needed in the early stages of the development process. We mostly start with a MicroControl workshop or webinar which will then be followed by support and advice in the research and development stage. If the decision has been made for CANopen classic or FD, the MicroControl experts will work in close liaison with the customer to realise hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually. With more than 25 years of experience in project management in a variety of industries, we will be your reliable partner for future solutions.

Request for a quoteResults for

Prototype manufacturing - Import exportNumber of results

43 ProductsCountries

Category

- 3D printers (11)

- Prototypes, industrial (10)

- Electronic data processing - microcomputers (2)

- 3D scanner (1)

- Additives for plastics industry (1)

- Bending - steels and metals (1)

- Bending machine tools (1)

- Cables & Networks (1)

- Ceramic manufacturing - machinery and equipment (1)

- Cutting - steels and metals (1)

- Hosting of online services (1)

- Import-export - medical and surgical equipment (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Nuclear power stations - installations and equipment (1)

- Optical measuring equipment (1)

- Plastic products for engineering (1)

- Plastics moulding (1)

- Precision mechanics (1)

- Rubber - technical items for industry (1)