- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- propeller

Results for

Propeller - Import export

INOXYDA SA

France

We manufacture propeller in aluminium bronze, delivered "as cast" , rough or fully machined according to international quality standards

Request for a quote

N. BOGDANOS MARINE BUREAU LTD.

Greece

Dutch Propeller Repairs BV specializes in all types of fixed and controllable pitch propeller inspections and repairs Repairs of propellers and blades at our workshop and on location worldwide. Certified repair specialists having over 25 years of knowledge and experience. Welding procedures certified by all well-known class-agencies. Independent inspections for ship owners, ship management and insurance organizations. Comprehensive reports of all our inspections and repairs. Balancing propellers and blades on location with our mobile balancing equipment within driving distance of The Netherlands. Blue fitting for propeller shafts / fixed pitch propellers and rudders / rudder stocks. Providing new propellers and blades on request. DPR BV is the only company in the world certified (by DNV-GL) for welding propellers in situ. FAST – FLEXIBLE – RELIABLE – COMPETITIVELY PRICED – CUSTOMER FOCUSSED

Request for a quote

SAMTRUCK

Turkey

Shaft Bearings, Joint Cross, Strap, Nuts, Seal Rings etc. We have all Trucks spare parts. Just contack us by mail or whatsapp number: export@samtruckt.com.tr Whatsapp: +90 535 830 18 19 Exports sales: Sami Caner

Request for a quote

DI - FAN DIKOFTSIS SOTIRIS

Greece

All our products are CE certified with EN12100, EN12761-3, EN907 standards and according to the European Directives 2006

Request for a quote

DI - FAN DIKOFTSIS SOTIRIS

Greece

All our products are CE certified with EN12100, EN12761-3, EN907 standards and according to the European Directives 2006

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

SPR - Standard-propeller-agitator The direct driven agitator SPR is Geppert Rührtechnik’s solution for all industrial mixing tasks that demand a turbulent mixing with high peripheral speeds. It is driven by a three-phase-motor with poles between 2 and 8 as well as drive ratings between 0.25 kW and 75.0 kW. The SPR could also be equipped with a frequency inverter upon request (up to 7.5 kW). The agitator shaft is directly connected at the shaft journal of the drive via sleeve or flange coupling. Solutions with quick-change or precisions-change coupling are also feasible for lower drive ratings of up to 3.0 kW. The standard agitator element is a propeller. Other mixing elements according to the mixing task upon request. The SPR can be mounted as a stationary unit or – at a weight of up to 25 kg – it can also be mounted directly onto the open tank via a vessel clamp Up to motor size 112, all SPR series agitators can also be provided with reinforced shaft. Type test certificate...

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

In the self-propelled grain cleaner ОВС-25D, cleaning is carried out not on 8, but on 9 sieves. The presence of an additional sieve allows better separation of pure grain and impurities. An additional sieve is installed in the housing of the auger of feed waste and divides them into two parts by size. Due to this, the ОВС-25D grain cleaning machine divides the grain into 4 fractions, and not 3 as ОВС-25 with 8 sieves. ОВС-25D has a capacity of up to 25 tons per hour. ОВС-25D, like other models of ОВС-25 grain cleaning machines we produce, is a self-propelled machine. ОВС-25D independently rides and loads itself with grain without the help of other mechanisms or personnel. Loading is carried out by a chain elevator, which is located in front of the ОВС-25D and picks up grain at a width of 5.3 meters. Grain cleaning in ОВС-25D is carried out both by regulated air flow and sieves, which allows to obtain high quality cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-60 self-propelled grain loader combines the advantages of a PZM-120M grain thrower and an auger grain loader. The grain loading speed and loader capacity are quickly regulated and range from 10 to 70 tons per hour. Unlike a conventional auger, PZM-60 moves independently and loads itself with grain with the existing scraper feeders. The pick-up width is adjustable and reaches 6 meters. During operation of the PZM-60 grain loader, there is practically no dust. The grain loading height is adjustable and ranges from 2.7 m to 4.27 m. The auger is installed on a special platform that rotates 280 degrees around its axis. This allows you to change the direction of grain loading in 2 seconds. The screw rotation speed is easily adjusted by the installed frequency converter. It is also possible to install a hopper on the PZM-60 screw loader. There is also the possibility of using PZM-60 for moistening grain by installing additional nozzles and a hydraulic pump.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The grain thrower PZM-120M is an ideal machine for fast loading of any grain into any transport. PZM-120M grain thrower is also used to transfer grain from one place to another. During the transfer process, moisture and light impurities are partially removed from the grain. Transfer of grain is necessary during its long-term storage. PZM-120M grain loader quickly loads grain into grain carriers, automobiles, railway cars, containers, barges, trailers, etc. A full load of a grain truck takes about 15 minutes. The grain thrower PZM-120M is used to work with grain, oilseeds, legumes and industrial crops, while the trauma to the grain is minimal (less than 0.1%). During the operation of the grain thrower, the grain is fed to the conveyor using scraper feeders. The conveyor loads the grain into the trimmer, which throws it through a special guide tube. The trimmer with the pipe easily rotates 257 degrees. Changing the direction and height of grain flight is carried out in less than 3 sec.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain cleaning complex OBC-70M4 is an ideal solution for cleaning, drying and loading grain any kind of transport. High cleaning quality is ensured by the use of a built-in mesh conveyor, sieves and a powerful adjustable air aspiration system. OBC-70M4 moves independently and cleans and loads grain without the help of other machines and people. This grain cleaner has a capacity of 80 tons per hour for all major crops. At the same time, energy consumption is only 0.25 kW / h for processing 1 ton of grain. The height of storage and loading of grain is up to 10 meters, the flight range of grain is up to 25 meters. Self-propelled grain cleaning complex OBC-70M4 has triple control - automatic, manual and remote. The design of this grain and seed cleaning equipment is as safe and convenient as possible. Anyone can work on OBC-70M4 after instruction, because it is very easy to operate this grain cleaning equipment.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25C self-propelled grain cleaning machine with a cyclone is the latest innovative development. Main advantages of using the OBC-25C: 1. Versatility - used for cleaning any kind of grain and seeds. 2. High quality cleaning and minimal damage to the grain. 3. Move independently and load themselves with grain without help of other machines or people. 4. Can independently load transport up to 3 meters high. 5. Easy and convenient operation and maintenance. 6. Capacity up to 25 tons of grains per hour. OBC-25C with a cyclone is the best self-propelled technique for high-quality and high-performance cleaning of grain, heap, cereals, legumes, oilseeds, corn, sorghum, sunflower, rape from impurities in open areas and in warehouses. You can also choose the model of the OBC-25C grain cleaning machine with an extended elevator, frequency converter, remote control, lighting, bumper, hopper, screw loader. OBC-25C is an ideal machine for cleaning grain.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Instead of a dust separator and a pneumatic conveyor, a cyclone is installed on a self-moving OBC-25CB grain cleaner, and a hopper instead of scraper feeders. The volume of the hopper of the OBC-25CB grain cleaning machine is about 1 cubic meter. OBC-25CB grain cleaner cyclone collectsdust, straw and light impurities. As a result, personnel can work without respirators and dust does not settle on already cleaned grain, people and equipment. The hopper of the OBC-25CB grain cleaning machine allows the grain truck to unload grain directly into the hopper, and not onto the floor. As a result, grain trauma, energy consumption and wear of the OBC-25CB loading conveyor are reduced. You can also load grain into the OBC-25CB hopper with a screw, noriya, loader, etc. Grain cleaning in OBC-25CB is carried out by adjustable air flow and sieves, which allows to obtain high quality cleaning. You can also purchase an OBC-25CB grain cleaner with a hopper and scraper feeders.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain loader with a large hopper PZM-170B is intended for unloading grain from grain carriers and trailers directly into the hopper of this grain thrower and subsequent loading of granaries to a height of up to 9 meters. Grain loader PZM-170B is also successfully used for loading grain carriers, trailers, wagons, ships, containers and trucks. The size of the hopper is 3.12 meters wide, 1 meter high with a lowered front wall, and a volume of about 4 cubic meters. It is convenient when handling grain in ports, grain warehouses and other premises, or in open areas. Self-propelled grain loader with a large hopper PZM-170B is used in the following sequence: grain loader PZM-170B drives up to the loading point on its own; the hopper is lowered into the working position and rests on the surface of the warehouse; a car, a loader or a tractor with grain drives up to the hopper; the loader throws grain through a special guide pipe to a height of up to 9 m and up to 25 m in lengt

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

ОВС-70L is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M4 is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer and sieves. Cleaning grain of any humidity or contamination is carried out using an aspiration system and a mesh conveyor. For better grain cleaning, a self-propelled grain cleaner OBC-70M4L is used. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-bag, hopper, or poured down. Functions performed by the self-propelled grain cleaner ОВС-70L: - cleaning grain heaps of legumes, grains, cereals, corn, sunflower, rapeseed, sorghum, etc .; - loading grain directly into vehicles with a side height of up to 3 m; - loading grain into big bags, bags, bins, loader buckets, etc.; - mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-70M4L is a self-propelled high-performance combination of a grain cleaning machine, a grain thrower and a grain loader, which minimizes human labor when cleaning, shipping and moving grain. OBC-70M4L has the following main advantages: 1. Versatility - the machine cleans,loads, moves and dries all kinds of grain. 2. Used for loading any kind of transport, handling and stacking any kind of grain into piles up to 9 m high. 3. Capacity up to 80 tons of grains per hour. 4. OBC-70M4L is a mobile machine and can be easily transported to another grain warehouse or to another farm. 5. Consume 0.25 kWh of electricity for cleaning, drying, loading and storage of ton of grain. 6. Move independently and load itself with grain without help of other machines or people. 7. Change the direction and height of the grain flight in less than 3 seconds. 8. Easy, safe and convenient operation and maintenance. 9. Minimal grain damage. 10. Good price and quick payback.

Request for a quote

NMG ITALIA - MOVING SOLUTIONS

Italy

The right compromise between range and agility, the MC 45S is a self-propelled electric crane able to amaze!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOXYDA SA

France

Aluminium Bronze alloys have been developped to face sea water corrosion issues. All Propulsion components in contact wuith seawater use aluminium bronze : - Blades, - Propellers, - Hubs, - Hub cylinders with 50 meting capacity in our Nantes - France plant, we can support most major projects for shipbuilding and navy applications.

Request for a quote

INOXYDA SA

France

We manufacture propeller/blades in aluminium bronze, delivered "as cast" , rough or fully machined according to international quality standards Third party inspection and 3.2 certificats with Lloyds, Bureau Véritas, DNVGL, RINA, Turkishes LLoyd...

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

AFS has been designed to ensure the better mixing performances, thanks to a high efficiency propeller.

Request for a quote

SRI - SAINT-REMY INDUSTRIE

France

We produce seal joints and bearings for propeller shaft in pure copper, aluminium bronze, tin and lead bronze as well as brass. Pieces are delivered as-cast, rough or fully machined.

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control panels for self-propelled machines based on documentation provided by the customer (electrical and mechanical), complying with the relevant requirements of PN-EN standards, including mining standards. Depending on the application and functionality, we offer the following types of control panels: • machine operator control panel (the most advanced technologically) • signal-control panel • control box The control panel product range is complemented by the electrical wiring harnesses, manufactured based on customer’s documentation. Application • to control self-propelled machines • to protect electrical devices of machines against the effects of short circuits and overloads • to monitor machine operating parameters (working time, fluids pressure and temperature, fuel consumption, air conditioning and others)

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control panel enclosures for self-propelled machines based on technical documentation provided by the customer, complying with the relevant requirements of PN-EN standards, including mining standards. Enclosures are intended for prefabrication of machine operator control panels, signal-control panel and control boxes, which are assembled on self-propelled machines used in: • mining of metal ores, especially copper ores • mining and processing of mineral resources • tunnel construction • infrastructure construction in road works, earth works and others

Request for a quote

SRI - SAINT-REMY INDUSTRIE

France

We produce blades and hubs in pure copper, aluminium bronze, tin and lead bronze as well as brass. Pieces are delivered as-cast, rough or fully machined.

Request for a quote

MARXAM PROJECT

Poland

The laboratory paddle stirrer is a versatile tool that can be used in a variety of settings, from homebrewing to laboratory experiments. Made from high-quality stainless steel, it is durable and safe for use with a wide range of liquids. The paddle design allows for efficient stirring and mixing, making it a must-have tool for any liquid-based project. We offer 15 different versions of laboratory stirrers and as a production company We can design a new version according to Your needs. Every stirrer is made out of steel for maximum durability.

Request for a quote

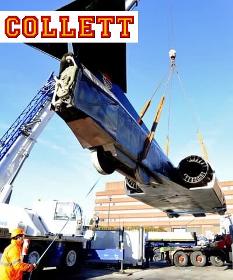

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Our fleet of hydraulic SPMTs provide the ideal solution for manoeuvring abnormal loads in confined spaces and intricately positioning components. The unique 360 degree manoeuvrability our SPMT trailer fleet allows our Team to undertake intricate transport and positioning of abnormal loads and heavy cargo in confined spaces. SPMTs are platform vehicles with hydrostatic driven axles, and regularly feature in our heavy transport and heavy lift operations providing an essential addition when undertaking the movement and positioning of abnormal loads, transformers, industrial cargo, vessels & tanks. The versatility of SPMTs allows them to be coupled in a variety of combinations tailoring to the specific cargo requirements. The unique hydraulic capabilities provide the ability to self load and off-load abnormal loads with a programmable steering option allowing multiple steering geometry patterns.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Under the Construction Plant-Hire Association (CPA) crane rental conditions the client is responsible for supplying all necessary lift plans, Appointed Persons (APs), Slingers, Banksmen and insurance. On behalf of our clients, and with our established crane supplier relationships, we can provide mobile crane hire on a rental basis as an integrated package with our transport operations. Alternatively these crane hire services can be provided in conjunction with our contract lift services as outlines above offering a complete solution. Whether it's manoeuvring machinery within a confined space, loading heavy cargo to an awaiting vessel, relocating transformers or positioning loads, our Team, utilising our jacking & skidding, crane hire and industrial services can provide an integrated solution.

Request for a quote

STOPARTS LTD

Turkey

Stoparts Ltd supply genuine Volvo Penta parts and quality aftermarket spare parts for Volvo Construction equipment and volvo Penta marine

Request for a quote

N. BOGDANOS MARINE BUREAU LTD.

Greece

HYDREX UNDERWATER TECHNOLOGY offers turnkey underwater repair solutions to shipowners wherever and whenever they are needed. Hydrex’s multi-disciplinary team can help to find the best solution for any problem encountered with a ship below the water line. Divers and technicians are immediately mobilized to carry out necessary repair work without the need to drydock. Every single day that a ship stays off-hire, causes the owner a substantial loss of money. This is where Hydrex comes in, in order to provide the owner with the most flexible and fastest assistance, throughout any underwater repair or maintenance operation of the ship. This can only be done successfully by people who have familiarity with such challenges and the relevant know-how to resolve all of the technical difficulties. This is why all Hydrex staff around the world undergo stringent training, after which they are able to perform a wide range of operations.

Request for a quoteResults for

Propeller - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Agriculture - Machines & Equipment (9)

- Milking - machinery and equipment (4)

- Shipbuilding (4)

- Fans (2)

- Lifts and platform elevators, car (2)

- Naval construction (2)

- Centrifugal pumps (1)

- Chemical industry - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Construction cranes (1)

- Control panels - electric (1)

- Diesel-engined boats - spare parts (1)

- Filtering equipment and supplies (1)

- Gardening and horticulture - machinery and equipment (1)

- Golf - equipment and supplies (1)

- Lorries (1)

- Machine tools, metal shaping - parts and accessories (1)

- Marine engineering (1)

- Marine, port and underwater works - contractors (1)

- Metal construction, lightweight (1)