- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- profile machining

Results for

Profile machining - Import export

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

Double sheet profiling machine. The machine makes 2 independent profiles tailored to the customer's requirements. For example, it can make a façade profile and a roof profile.

Request for a quote

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

In our catalog for coatings, machining and profiles for belts, you will find all the different possible materials for coatings of belts. The possibilities for machining and amny examples for transportation cleats and profiles.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

PRESSTA EISELE GMBH

Germany

High performance automatic circular saw for aluminum and non-ferrous metals Fully automatic operation Infinitely adjustable speed control of the saw blade engine Material and saw feeder movement through servo driven ball screw spindle 2 axis CNC control Siemens S7 with 7” touchscreen Cutting range: up to 205 mm height and up to 400 mm width Rest-piece length as short as 55 mm (depending on profile) Machine can use carbide (TCT) or PKD blades diameter 650 mm (smaller diameter upon request) Automatic kerf widening to reduce scratches Individually controllable clamping pressure Motorized material feed with servo driven ball screw Pneumatic material clamps individually adjustable Positioning of the vertical and horizontal clamps by hand-wheel Cut off lengths of up to 5000 mm are possible by reversing the material feed up to 5 times Floating material feed to reduce material abrasion Feeder length of 1000 mm Simple exchange of saw blade, accessible from the front Saw blade feed is...

Request for a quote

NORELEM FRANCE

France

Angle diecast zinc. Screws and slot nuts steel. End cap polyamide, fibreglass reinforced. Version Angle painted aluminium tone. Screws and slot nuts electro zincplated. End cap black. Note Suitable for reinforcing profile constructions and for frictional connection of profiles with each other without machining. Can also be used as fastening element (e.g. bracket) for any components. The angles have centring lugs for accurate and twistproof mounting. The centring lugs can be removed if necessary by breaking off i.e. for mounting plates. The open side can be closed off with the end cap.

Request for a quote

NORELEM FRANCE

France

The connecting sets are used to connect two aluminium profiles at right angles. They allow free position of the profiles. The profile slots positioned at rightangles to each other remain free. Panel elements can be positioned in the profile slots without additional machining. Due to the reduced clamping force and omitted rotation locks, these connecting sets should only be used in combination with panel elements and lightly loaded constructions. Low workload. To assemble a hole must be drilled into one of the profiles. The D2 hole can also be drilled through.

Request for a quote

AAAGILER GMBH

Germany

We offer sanding belts suitable for the following manufacturers of long belt, edge and profile sanding machines: CMC, Fein, Flott, Greif, Hessemann, Hess, Holzmann, Holzkraft, Johannsen, Kündig, Kuhlmeyer, Löser, Löwer, Niederberger, Quick Wood, Scheppach, SCM, Stähle, Vohbag and Wegoma. We also offer quality sanding belts suitable for the following manufacturers of hand sanders: AEG Powertools, Atlas Copco, Black & Decker, Bosch, DeWalt, Einhell, Festool, Fein, Felisatti, Flex, Hitachi, HOLZ HER, Kress, Löser, Makita, Metabo, Milwaukee, Peugeot, Ryobi, SKIL, Stayer and Suhner. And if you can't find what you're looking for in our standard range of abresive belts, we can also supply custom-made sanding / grinding belts.

Request for a quote

SIKO GMBH

Germany

The WH58MR rotary encoder is a magnetic safety rotary encoder with redundant position detection and hollow shaft, which has been specially developed for use in mobile machines. It can be used in safety-critical applications – up to performance level PLd. Thanks to its particularly robust design, an optionally redundant CANopen or CANopen Safety interface, it is ideally suited for tough conditions in mobile machines. Profile WH58MR:

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our experts continually innovate and optimize our range of abrasives, making Tyrolit a trusted partner in the automotive industry and other sectors requiring precise gear grinding. We offer a comprehensive assortment of grinding wheels, cup wheels, and worm grinding wheels for generating, bevel gear, and profile grinding. Generating gear grinding uses a worm grinding wheel to continuously grind the desired profile into the workpiece. Unlike this, profile gear grinding machines each gear tooth individually, suitable for large gears. Tyrolit's vitrified-bonded profile grinding wheels have set industry standards, delivering exceptional cost-efficiency, process stability, and finish quality for gears of all sizes. With increased quality requirements, hard-fine machining of gears is essential. Tyrolit's special cup wheel line for bevel gears ensures exact topographies and pitches, offering high productivity, low thermal load, and maximum profile retention.

Request for a quote

ESTIMET SP Z O.O.

Poland

One of the areas of ESTIMET's offer is laser cutting, used for precision processing of sheet metal, pipes and profiles. In ESTIMET's machine park we have two fiber lasers of 6 kW and 8 kW. Thanks to these devices, we can precisely cut elements with maximum dimensions of 2000 x 4000 mm. Our laser cutting services comply with the EN 1090 standard, as confirmed by the CE mark. We are ready to take on even the most demanding orders, offering to cut sheet metal made of a variety of materials, such as carbon steel, stainless steel, aluminum, copper or bronze. We also have a gas burning machine, dedicated to metal sheets up to 150 mm thick. In addition, we have specialized machines for cutting pipes, profiles and sections with maximum dimensions of 450 x 450 mm. We can cut tubes and profiles in straight sections as well as at an angle. The range: steel: 0,5 - 25 mm INOX: 0,5 - 30 mm aluminum: 0,5 - 25 mm brass: 0.5 - 10 mm copper: 0.5 - 10 mm galvanized: 0.5 - 4 mm

Request for a quote

APD MAQMASTER

Spain

Developed to perform cutting, surface treatment and milling operations on wide aluminum and PVC profiles. It is designed to achieve greater efficiency in the shortest time with its units that can operate independently of each other

Request for a quote

APD MAQMASTER

Spain

1. Advanced industrial 3-axis CNC profile machining systems. 2. Suitable for processing aluminum, PVC and other light metal materials; 3. The machine completes precise milling, drilling, slotting and other multifunctional functions in one go. 4. Work table with pneumatic positioning -90°/0°/+90°. Optional 45 degree milling function is available. 5. Adopts high-precision ball screws to ensure smooth movement, high-precision positioning and processing. 6. The operating platform of the system: Linux platform. English, Chinese, Thai, Korean and Vietnamese languages are available. 7. The latest version of the system: 4G 4-core memory, fast and smooth operation. 8. Additional one meter support table for special processing of long profiles. 9,400 mm high safety lid for safe operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

APD MAQMASTER

Spain

1. PA2CNC EASY II CNC automatic cleaning machine equipped with 7 tools for complete cleaning of the welded corner capable of working profiles of any shape (linear, internal radius, external, etc.), with a maximum height of 185 mm and a minimum of 35mm. The integrated tools are: a) two reversible blades for cleaning the flat part with one side dedicated to finishing with trenches and the other to rinsing; b) radial blade to clean the rounded part; c) an upper and a lower vertical milling/drilling unit for different types of processing such as joint channeling or particular finishes depending on the shape of the profile; d) Ø250 blade with movement in two axes; e) hook for cleaning the anchoring area of the glass ball. 2. Automatic dimensional self-recognition of the profile to be machined and positioning with automatic centering of the square to be cleaned.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Aluminium Machining - Your Premier Provider of Proficient Profile Production and Processed Products At Aluminium Machining, we take pride in offering comprehensive services to our esteemed customers. Our expertise extends beyond profile production, as we also specialize in delivering top-notch processed or finished products utilizing the latest CNC and mechanical processing centers. With our state-of-the-art facilities, we guarantee precise cutting up to 5 mm, maintaining a remarkable tolerance of ± 0.1 mm. Our double-head saws enable us to effortlessly execute angled cuts ranging from 350mm to an impressive 12000mm. To further cater to your specific requirements, we possess the capability to conduct drilling, unloading, and die-cutting processes using eccentric presses. Additionally, our proficient team can seamlessly perform CNC milling and unloading processes, ensuring unparalleled precision and efficiency.

Request for a quote

KMC GROUP - MEKO METAL

Turkey

Bending with standard tube and profile bending machines, Cutting and punching operations on all profiles with special templates or if it is necessary by hydraulic or pneumatic machines that can be designed and produced ourselves, Cutting of the profiles done with CNC saws in requested length.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

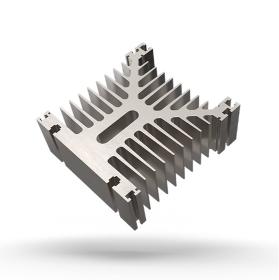

Seifert heat sinks are designed for both natural and forced cooling applications. From standard heat sinks to individually machined custom profiles, we offer the appropriate heat sink in the desired profile. The standard heat sinks from Seifert electronic GmbH are classic finned heat sinks, primarily intended for natural cooling. However, these heat sinks can also be utilized for forced cooling with airflow. Thanks to the extensive variety of profiles in our standard range, we can fulfill almost any heat sink requirement. From small transistor coolers to profile giants for IGBT cooling, measuring up to 900 mm in width, we provide the right profile for nearly every application. In addition to our standard profiles, we have access to open profiles, offering the possibility of further variations without incurring tooling costs.

Request for a quote

CNC CREATIONS

United Kingdom

Delivery within 7-10 working days (subject to quantity and location). Please note, the machining process of these panels may cause the material to bow. Available in 10mm and 19mm Thickness. Product – Finsa Fibracolour Negro The dimensioned drawing shows the profile of the panel when machined with a brand-new cutter. The effect of sharpening on the cutters softens the profile slightly. This is only noticeable when comparing one panel against another that were purchased separately at different times.

Request for a quote

TECHNIC MACHINES

Turkey

Our Polycarbonate Extruder Lines have different production capacity and different final PC final product alternatives, so that we can match with our customer's research. Our Polycarbonate and PC Extrusion Line can be used for different fields such as PC polycarbonate glass, PC polycarbonate hollow sheet, PC polycarbonate profile, PC polycarbonate led light, PC polycarbonate roofing sheet, PC polycarbonate sheet and etc.. Today polycarbonate final prouducts are pretty popular product in many different fields. Polycarbonate profiles are used as led light or etc. Polycarbonate hollow sheets are used in fields green housing, factory roofs etc. Polycarbonate sheets are used also in fields as military, automative, general construction etc. Just contact with us for your research on PC polycarbonate extruder machine, we will offer you the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

We have options for WPC extruder lines, we provide WPC extruder machines with different capacity and different WPC final product as to our customers request. We offer WPC extruder machines for different product options. For example WPC decking extruder, WPC board production line, WPC profile extruder machine, WPC foam board production line, WPC flooring extruder machine and for other WPC extruder machines. Popular WPC Products - WPC Flooring - WPC Foam Board - WPC Board Panel - WPC Profile - WPC Decking Just contact with us for your WPC extruder machine research, we will provide the optimum solution.

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quoteResults for

Profile machining - Import exportNumber of results

98 ProductsCountries

Category

- Machines for the manufacture of PVC and Aluminium Doors and Windows (17)

- Milling - machine tools (7)

- Forming - steels and metals (6)

- Mechanical engineering - custom work (6)

- Extrusion, plastics - machinery (5)

- Adjustment - machine tools (4)

- Rolling machines (3)

- Electronic components (2)

- Grinding - machine tools (2)

- Mechanical transmission - components (2)

- Milling - steels and metals (2)

- Sawing machine tools (2)

- Abrasives, mechanical (1)

- Aluminium and aluminium alloys (1)

- Bending - steels and metals (1)

- Connectors, pneumatic (1)

- Conveyor belts (1)

- Crimping machines (1)

- Cutting - machine tools (1)

- Cutting - steels and metals (1)