- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production of tools

Results for

Production of tools - Import export

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

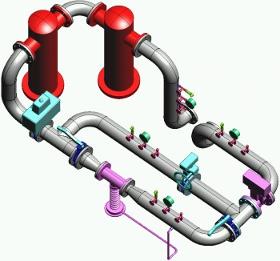

SKID PRESSURIZATION FOR PLANES INFLATING BENCHES - Stainless skid including the whole instrumentation necessary for piloting - Air filter - Automaton and supervision piloting - Various pressures acquisition - Pressure control at 1,2 mbar/s TOOLING PDOS : POWER DOOR OPENING SYSTEM : This tooling permit: - PDOS electrical supply in 115Vac/400 Hz and in 28Vdc le PDOS, - The jack purge of the driving hoods, - Driving hoods opening and closure (Fan and reverses), - Secure the staff during the operation. HEATED BOX FOR COMPOSITE MATERIAL : - 6 m length welded structure, - Heated box 5,5 m length x 1,5m width, - Heated box flatness 5/10 mm/m, - Vacuous putting system 600mbar, - Temperature setting nd cooling by heat transfer fluid, - Heating capacity of 150kW, - Automaton and supervision piloting

Request for a quote

«ROBOTKOMPLEKT» LLC (DKR GROUP)

Russia

Oil piston compressor La Padana ED 25/2M with innovative solutions and sophisticated design combining quality and reliability with special attention to the needs of the user. For professional use. •Modular design and compact size. •High efficiency and productivity. •Reduced operating costs due to low power consumption. •Minimum maintenance costs. •Excellent price/quality ratio.

Request for a quote

«ROBOTKOMPLEKT» LLC (DKR GROUP)

Russia

The control panel of the washing complex is made of stainless steel. The panel has 6 functions, 4 of which are basic (water, water with foam, foam and wax), and 2 additional ones - at the customer's choice (active dry cleaning for the body/disks, osmosis, mosquito, air blowing and vacuum cleaner). The panel also has a pause button, which, if desired, can be replaced with another function.

Request for a quote

PROGRESS SILICONES

France

A qualified and experienced team that is fully involved in the projects of each and every one of our customers assists and advises you for studying your specific needs. We have the capabilities to produce moulds tailored to your specifications and unique needs. Our in-house machine shop provides crucial support, producing and optimising your production tools but also for the realization of rapid prototyping. Thanks to the expertise and commitment of its employees, Progress Silicones guarantees top manufacturing quality, competitive prices and fast response times.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Static tools form one of the EWS core areas. There is no other manufacturer in the world offering such a variety of products: More than 20,000 different tool holders are available for machine operators. Our portfolio includes VDI tool holders with shaft diameters of 16-80 as well as block tool holders of BMT55-BMT85 to machine-specific holders for MAZAK, Okuma or Mori Seiki, to name just a few. We also offer prism holders according to DIN 69881 (VDI3425 Bl.3) in all nominal sizes. Our standard portfolio includes Capto, HSK, KM and ABS adaptations in addition to the standard holders. Moreover, our scope of supply includes special holding fixtures made according to customer drawings or innovative solutions of the EWS engineers designed to master production engineering challenges. The tool holders are manufactured at our factory in Uhingen and rightly carry the label: Made in Germany! Boring bar holder BMT Capto C4 Double boring bar holder Capto Bar Gripper Infee

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor that influences the service life and productivity of the expensive machine tools: The key challenge here is therefore process reliability. For efficient swarf management, ERDWICH offers proven centralised and decentralised solutions with the following benefits: Whether centralised or decentralised, Erdwich lets you handle swarf management in double-quick time. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

TRANSMEC BELGIUM

Belgium

Evaluating the status quo Identifying improvements and areas for optimisation Defining new procedures Rationalising stock levels in relation to production times IT tools to interface with the main ERP applications on the market, providing full monitoring data on the customer’s entire supply chain Production material management Handling, supply of production lines, JIT and JIS feeding, job order preparation Storage, stock control, customer order preparation and packaging, packing, labelling, product configuration, kitting and customisation.

Request for a quote

MICRON AMERICA

Turkey

Please see the related products section down below for attaching tools needed for this type of grommet hand press machinery, hand tools or powered machinery.

Request for a quote

SYNERLINK

France

EL MERGE is an automated merger tool. The products (single cups and packs) are either picked-up when stationary or dynamically grouped and picked-up without stopping. This equipment allows transfer of several tracks to one or more tracks. The stacks might be packed according to product heights.

Request for a quote

MICRON AMERICA

Turkey

Please see the related products section down below for attaching tools needed for this type of grommet hand press machinery, hand tools or powered machinery. For best results use our #18 hand tools.

Request for a quote

MAROVT D.O.O.

Slovenia

By using serial tools for the production of prototypes we can save your time The prototype pieces are the key for the efficient serial production. This is why we pay a lot of intention to all prototype processes as well as all processes before the serial production. This phase is intended for taking down all data and information which are vital for the implementation in the serial production. Based on the foreseen technology, which is the result of experience and data from the simulation equipment, we produce serial production tools for the production of prototype pieces in our company. Because we use serial tools for prototype production, we do not need additional time and special adjustments to transition to classic serial production. This gives us the advantage of being able to offer serial production within the shortest possible timeframe.

Request for a quote

KELTEKS

Croatia

Our range of accessory products for solidian reinforcement helps you to install our reinforcement products quickly and safely. Tools and installation aid complete the range. We do not only think holistically but also act accordingly! Our special portfolio of solidian SPACERS is perfectly matched to our reinforcements and their possible applications. With the patented solidian SPACERS for closemeshed products, we simplify the application for highquality, filigree exposed concrete, e.g. for curtain walls, where a particularly perfect concrete surface and appearance is required. We also offer connecting materials for tying mats and bars.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

In IKO Needle Roller Bearings with Separable Cage, the inner ring, outer ring and IKO needle roller cage are combined, but they can be separated easily. This type has a simple structure with high accuracy. In addition, the radial clearance can be freely selected by choosing an assembly combination. Because they use needle roller cages, these bearings have excellent rotational performance, and are best suited for massproduction, high accuracy products such as machine tools, textile machinery, and printing machines.

Request for a quote

HOCHRAINER GMBH

Germany

Different systems can achieve the objective depending on product requirements: Machine tools for type VSMH rotary transfer machining (hydraulic) Machine tool for type VSMK rotary transfer machining (cam-controlled) Type NBM finishing machines for stamped, moulded, and cold extruded parts Our years of experience in complete machining of serial parts passes to the next generation in constructive and innovative cooperation.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

crimping tool for crimping our contact sleeves and -pins from 1,5 mm² / 2,5 mm² / 4 mm² and 6 mm² Category Electrical equippment for vehicles / Accessories / Crimping tools Product number supplier 209070

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CIC will be happy to support you in planning, securing, controlling, monitoring and optimizing your quality management, e.g. with: advanced quality planning supplier quality purchased part quality component qualification product engineering Supplier Audit Internal audits Process monitoring and process optimization Production control and monitoring at the supplier bottleneck coordination production readiness tool design Tool tracking mold trials Gauge concepts and gauge acceptance component measurements Resident Engineering Task Force Abbreviations such as APQP, PEP, FMEA, PPAP, 8-D, 5Why are not foreign words for us but common tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In high-pressure grinding, the quality of the grinding wheel is crucial for the process result. It determines whether economical snagging of steel can meet technological requirements. Tyrolit's high-performance grinding wheels are designed to quickly and precisely achieve the required quality for further processing, supporting the production process. Snagging is the most common process for plastering semi-finished products. Our tools ensure high process quality, targeted and controllable stock removal, high production output, and consistent surface quality. They also guarantee high economic efficiency, easy handling, and low fault susceptibility. The SECUR line abrasives demonstrate the capabilities of our product range in high-pressure grinding. Many steel grades have surface defects, scales, and decarburization zones after continuous casting, which must be efficiently fettled before rolling mill processing.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

crimping tool for crimping our contact sleeves and -pins from 1,5 mm² / 2,5 mm² / 4 mm² and 6 mm² Category Electrical equippment for vehicles / Accessories / Crimping tools Product number supplier 209070

Request for a quote

AAAGILER GMBH

Germany

Shopfloor Management 4.0 means digital dashboards / visualisation of relevant KPIs on large flat screens for daily discussion with production staff. Get the latest tools used by the German industry.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision manufacturing, demands on surface quality and component accuracy are continuously rising. Tyrolit's first-class abrasives ensure precision and functionality in products across all industries, such as watchmaking, eyewear or medical technology. Tyrolit's product portfolio guarantees high-quality machining of components with extremely narrow tolerances, whether for individual pieces or mass production. Our tools meet the most demanding dimensional tolerances. In the electronics industry, we supply cool-grinding diamond ring wheels with special bonds for wafer machining and long-lasting electroplated diamond grinding points for electronic components. The watch and eyewear industries rely on our elastic bonded grinding and polishing tools for precision mechanics components, ideal for deburring, fine grinding and polishing. For medical products we offer vitrified and resin-bonded grinding tools for knee and hip joints and silicon carbide wheels for pointing hypodermic needles.

Request for a quote

MESUTRONIC GMBH

Germany

METAL SEPARATOR FOR THE PHARMACEUTICAL INDUSTRY FOR THE INSPECTION OF TABLETS AND CAPSULES. Detects and separates all metals encapsulated or as loose parts. Meets the highest h ygiene requirements. Fast decontamination of all product touching parts without tools. Fits every tablet press and deduster installation. High throughput owing to round equipment design DN50.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-EU pressure blasting cabinets clean and process tools and parts in just a few seconds. Fine blasting granulates are shot onto the surface by means of compressed air and remove dirt and corrosion. The blasting nozzle is manually guided during the processing of individual parts. Process automation is also possible. For this purpose, the workpiece or the blasting nozzle is moved by motor. The pressure blasting process is suitable for the removal of all solid, exposed residues and layers, especially on metallic surfaces of production tools and high-quality machine parts. Deburring and finishing of surfaces is also possible. In extensive tests with your tools you can convince yourself of the economic efficiency of our system. We will provide you with a test facility for this purpose after consultation.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-BB blast cabinets with combined blasting and blow-off function (Blast´n´blow®) and ex-protection accord. to 1999/92/EC for paint stripping and surface decoating in seconds. Fine organic blasting media get shot onto the workpiece by compressed air, whereby even stubborn thick layers are loosened in shortest time by the effect of the soft, but sharp-edged granulates. Even sensitive tool surfaces get not damaged. The blasting process is suitable for the removal of all solid, exposed residues, especially on metallic surfaces of production tools and high-quality machine parts. Blasting granulate and blasting pressure are adapted to the respective application. With the pressure blasting process you can clean extruder and injection moulding screws, blowing heads, moulds and profile tools much faster and more gently than with conventional cleaning methods. In extensive tests with your own workpieces you can convince yourself of the economic efficiency of our system.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quoteResults for

Production of tools - Import exportNumber of results

147 ProductsCountries

Company type

Category

- Milling - steels and metals (21)

- Casting of special and high-grade steels (20)

- Wood - turned products (8)

- Bags (5)

- Lifting equipment (5)

- Food industry packaging machinery (4)

- Milling - machine tools (4)

- Palletising machinery (4)

- Tools & Hardware (4)

- Packing and packaging - machinery and equipment (3)

- Grinding - machine tools (2)

- Handles - tools, wooden (2)

- Machine tools, metal machining - parts and accessories (2)

- Measurement - Equipment & Instruments (2)

- Plastics moulding (2)

- Rubber - technical items for industry (2)

- Sandblasting equipment (2)

- Sensors (2)

- Wines, sparkling (2)

- Bearings - ball, needle and roller (1)