- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process engineering

Results for

Process engineering - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

The search for solutions in the field of process engineering systems and methods presents us with new challenges every day. Electric heaters for the direct thermal treatment of incoming air in air conditioning systems or as preheater or afterburner for intake air in industrial equipment using intelligent processadapted control systems are gaining an increasing acceptance

Request for a quote

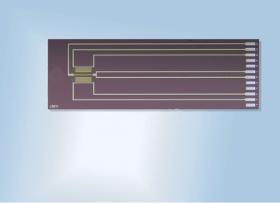

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The SFS01 is particularly suitable for low flow velocities up to 3.5 m/s (in gases). It shows very fast measurement results of the flow rate as well as the flow direction. The Silicon Flow Sensor SFS01 offers three main characteristics: — Very fast response time <5 ms — Very low energy consumption — Easy system integration including temperature compensation Well-adapted channel geometries allow the performance of the sensor to be optimally aligned to the desired application. The SFS01 flow sensor is ideally suited for space-limited applications, but can also be easily upgraded to complete ready-to-use systems. Suitable application areas for the SFS01 flow sensor are flow measurements in battery-operated / portable devices, air conditioning technology (HVAC), automation technology as well as process and control engineering.

Request for a quote

IGUS® GMBH

Germany

Other information Installation video: Instructions for the opening and closing of the E-Tubes Series R117 Inner height hi: 21 mm Inner widths Bi: 20 - 100 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, snap-open along the inner radius on both sides Series R118 Inner height hi: 21 mm Inner widths Bi: 20 - 100 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, snap-open along the outer radius on both sides Series R157 Inner height hi: 40 mm Inner widths Bi: 40 - 200 mm bending radii R: 100 - 250 mm Pitch: 46 mm E-Tube, snap-open along the inner radius on both sides Series R158 Inner height hi: 40 mm Inner widths Bi: 40 - 200 mm bending radii R: 100 - 250 mm Pitch: 46 mm E-Tube, snap-open along the outer radius on both sides Series R167 Inner height hi: 50 mm Inner widths Bi: 50 - 250 mm bending radii R: 100 - 300 mm Pitch: 58,8 mm E-Tube, snap-open along the inner radius on both sides Series R168 Inner height hi: 50 mm Inner widths Bi: 50 - 250 mm bending radii R: 100 - 300 mm Pitch: 58,8 mm E-Tube, snap-open along the outer radius on both sides iF-Design-Award for Series R117/R118 and Series R68 ESD classification: Electrically conductive ESD/Atex versions on request UL94-V0 Classifications on request E-Tube made of igumid HT: Hot chips (to 850°C) cannot burn into it. Supplied as a special design on request Other information Series R117 Inner height hi: 21 mm Inner widths Bi: 20 - 100 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, snap-open along the inner radius on both sides Series R118 Inner height hi: 21 mm Inner widths Bi: 20 - 100 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, snap-open along the outer radius on both sides Series R157 Inner height hi: 40 mm Inner widths Bi: 40 - 200 mm bending radii R: 100 - 250 mm Pitch: 46 mm E-Tube, snap-open along the inner radius on both sides Series R158 Inner height hi: 40 mm Inner widths Bi: 40 - 200 mm bending radii R: 100 - 250 mm Pitch: 46 mm E-Tube, snap-open along the outer radius on both sides Series R167 Inner height hi: 50 mm Inner widths Bi: 50 - 250 mm bending radii R: 100 - 300 mm Pitch: 58,8 mm E-Tube, snap-open along the inner radius on both sides Series R168 Inner height hi: 50 mm Inner widths Bi: 50 - 250 mm bending radii R: 100 - 300 mm Pitch: 58,8 mm E-Tube, snap-open along the outer radius on both sides Installation video: Instructions for the opening and closing of the E-Tubes E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining and separating of the E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E2 R100 and E2 R Chip protection, swivelable Excellent protection against chips (even hot chips) Rugged and tight Snap-open alternately along inside or outside - Swivelable or removable lid, short installation time Space-saving through good internal/external dimensions ratio Modular interior separation options Double stop dog system for longer service life and long, unsupported lengths Universal KMA mounting brackets with potential for "all-round" fastening Typical industrial sectors and applications Machine tools Timber Processing Machines General mechanical engineering etc In all areas exposed to dirt and chips iF-Design-Award for Series R117/R118 and Series R68 ESD classification: Electrically conductive ESD/Atex versions on request UL94-V0 Classifications on request E-Tube made of igumid HT: Hot chips (to 850°C) cannot burn into it. Supplied as a special design on request

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Special cylinders developed and manufactured according to individual customer requirements, specifications or specifications. Both as a completely custom-made special cylinder or modified inexpensively using standard elements with adjustments in form, function, mount, connection or material.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The FEDOS E is the latest development in the FEDOS series, combining proven features with modern dosing technology requirements. It offers improved flexibility and efficiency in process engineering applications. Piston dosing pumps are robust and accurate, ideal for precise liquid dosing in various industries. Their simple mechanism ensures reliability and durability. Key features: . Precision: Accurate dosing . Robustness: Durable and resistant . Flexibility: Processes different liquids . Easy maintenance: Easy to maintain Piston dosing pumps are ideal for applications that require high accuracy and durability.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate valve type 8040 in the long design is universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant construction. This sliding gate valve with its small stroke achieves a very high switching capacity with extremely short switching times.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate valve type 8040 in reinforced design and long construction is universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant construction. This sliding gate valve with its small stroke achieves a very high switching capacity with extremely short switching times.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The self operated pressure regulator Type 8011 in a reinforced version with closed spring cover in the form of a pressure reducing valve (downstream pressure regulator) or an excess flow valve (upstream pressure regulator) is used in a wide range of process engineering control tasks. Media such as steam, liquids, gases, etc. can be excellently controlled without auxiliary energy.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The self operated pressure regulator type 8011 with closed spring cover in the form of a pressure reducing valve (downstream pressure regulator) or an excess flow valve (upstream pressure regulator) is used in a wide range of process engineering control tasks. Media such as steam, liquids, gases, etc. can be excellently controlled without auxiliary energy.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

This compact motor valve is used in a wide range of process engineering control tasks. It is particularly characterised by its very short design. Most media such as steam, fluids, gases, etc. can be excellently controlled with it. This inexpensive version represents a real alternative to pneumatic actuators. Position electronics Analog stroke feedback Limit switch Fail safe feature . . .

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate valve type 8041 in the short design is universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant design. This sliding gate valve with its small stroke achieves a very high cycle capacity combined with extremely fast cycle times. Metal bellows Limit switch Pilot valve Stroke limitation . . .

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 HME series is a design with bearingless cantilever construction that is directly coupled to the IEC Motor. Specially designed for plant engineering and confined installation conditions. It can be operated in dry installation next to the tank, thus facilitating access for maintenance and repair work. The pump is suitable for pumping /circulating neutral, corrosive and mechanically contaminated liquids. However, it can also be used in stationary installation in the chemical industry and process engineering, in surface and electroplating technology and in gas scrubbers. * temporarily also possible in dry running * directly coupled in bearingless cantilever design * available in immersion depths from 275 - 450 mm Features & Advantages * Service friendly dry running installation * Extremely low vibration and wear operation * Self-centering alignment in the bearing shell * All wetted parts made of corrosion resistant plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Process engineers worldwide use Datapaq temperature profiling and monitoring systems to optimize product quality, reduce waste, confirm compliance with industry standards and more. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution – complete with data logger, custom thermal barriers and our Insight™ Software. These bespoke systems enable through-process temperature profiles to be obtained in processes where trailing long thermocouples are not an option. Each thermal barrier is designed in close collaboration with the end-user, providing the optimum solution for every application. Data Loggers Fluke Process Instruments has a wide selection of data loggers ranging from the stainless steel cased Datapaq TP6 and the rugged Datapaq DP5 for high temperature heat treating to the Multipaq 21, Datapaq XL2

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate control valve type 8043 in a reinforced version and long design with piston actuator and integrated positioner is due to its compact design universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant design. Due to the direct and backlashfree installation of the positioner on that piston actuator, these valves have no exposed moving parts and are characterized by a high control quality and control dynamics. Digital positioner type 8049 Electropneumatic positioner type 8047 Pneumatic positioner Positioner with integrated process controller Metal bellows Limit switch Position feedback Pilot valve . . .

Request for a quote

LUTZ PUMPEN GMBH

Germany

The diaphragm dosing pumps in the MEMDOS MR series have been developed for a wide range of applications in dosing technology. They are ideal for use in industry, process engineering, water treatment and waste water treatment. Features: . Robust dosing head: Made of PP and stainless steel for high durability and longevity. . Precise dosing: Double ball valves (up to MR 290) and spring-loaded flat-seat valves (from MR 290), optional spring-loaded single ball valves. . Safety: Separation chamber with drainage tube between dosing head and gearbox protects against leaks. . Flexible stroke adjustment: Can be adjusted manually or electrically (ATE). Optional extensions: . Dual dosing pumps for increased performance. . Stroke counting with inductive sensor for precise batch processes. . Frequency inverter control for variable control.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

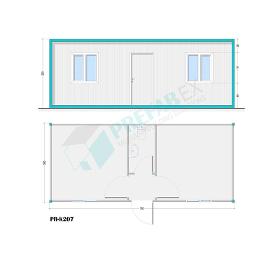

PREFABEX MODULAR BUILDING SOLUTIONS

Turkey

We are proud of the high quality modular on-site container buildings that we deliver to commercial, manufacturing, education facilities, government, oil and gas, defence industry, and a wide range of clients. Every container is designed and manufactured under strict quality control. You can choose from an extensive range of add ons and accessories to enhance the shape and functionality of your container such as cladding, flooring, interior finishes and kitchenette and bathrooms. Environmentally friendly upgrades including laminated windows, underfloor insulation are also available. Portable site containers takes place within controlled plant and with this comes process engineering and high quality control procedures. Among the many advantages offered by our on-site containers: Affordable prices and high quality Easily transportable / relocatable Easy to assemble Expandable – add additional containers Wind and waterproof, very secure Custom built to your specifications

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

BIOGAS FOR INDUSTRY, MUNICIPALITIES AND AGRICULTURE In addition to tank construction, LIPP built the first biogas plant in Germany in the 70’s. Furthermore, LIPP was one of the first companies to develop and sell small biogas plants in the early 80’s. By steady advancements in production technology and the materials used, as well as extensive experience in process engineering LIPP has installed in collaboration with its partners, hundreds of biogas plants in Germany and worldwide. The majority of these projects are still in operation and ensure proof of the high quality and the technical and economic performance of Lipp’s system solutions. LIPP provide system solutions for biogas production in the following areas APPLICATIONS anaerobic wastewater treatment plants waste fermentation plants sewage sludge digestion agricultural biogas plants

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate control valve type 8043 in long design with piston actuator and integrated positioner is due to its compact design universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant construction. Due to the direct and backlashfree installation of the positioner on that piston actuator, these valves have no exposed moving parts and are characterized by a high control quality and control dynamics. Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Metal bellows Limit switch Position feedback Pilot valve . . .

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The sliding gate control valve type 8044 in short design with piston actuator and integrated positioner is due to its compact design universally applicable for neutral and aggressive media in the chemical industry, process engineering and plant design. Due to the direct and backlashfree installation of the positioner on that piston actuator, these valves have no exposed moving parts and are characterized by a high control quality and control dynamics. Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Limit switch Position feedback Pilot valve . . .

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Today resistance thermometers are one of the important precision and operating measurement instruments of technical temperature measurement. Fast and easy testing of display, control and recording devices in measurement and process engineering is essential. Fixed temperature values can easily be simulated according to the characteristic curves of Pt100, Pt500 and Pt1000 using the precision resistors calibrated in °C (the inscription also includes the resistance value in Ω). The small dimensions of the resistors allow the installation in measuring instruments or measuring circuits for comparison or control measurements. Features: — TK ≤ 10 ppm/K — More than 60 fixed temperature values from -200 °C ... +800 °C ex stock — Calibration in acc. with DIN EN 60751 n - 0.02 % tolerance for the models 1144-Pt 100, 1144-Pt 500 and 1144-Pt 1000 — ± 0.05 % tolerance for model 1146-Pt100 — Resistance material MANGANIN®

Request for a quote

ANTHERMO GMBH

Germany

Universal use for a wide range of applications Ice stores are used in more and more areas of technology. In addition to the classic areas of application in refrigeration, air conditioning and commercial kitchen technology, ice storage systems and cold water systems are increasingly being used in process engineering systems. Cold water for subsequent production processes is generated with ice storage tanks. Ice storage systems thus provide stored cold. Use of cheap night electricity tariffs With the help of ice storage technology, cheap nighttime electricity tariffs can be used. During the night, ice is continuously built up on the plates or on the pipe coils. This ice is then available during the day as stored cooling capacity. This can significantly reduce energy costs. The cooling units can also be made smaller when using ice storage systems.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix supplies key components to optimize the production of light foams such as XPS insulation boards, XPET construction boards, XPE foam films, etc. Thanks to the improved cell structure, the foam density can be further reduced, and the throughput of the plant increased, resulting in significant cost savings in production. Replacement of iso-butane for the sake of the environment Iso-butane and other hydrocarbons are excellent blowing agents for high expansion foam production.However, they are also highly harmful to the environment and highly flammable, which increases the production risk. Promix gas dosing stations in combination with other retrofittable process engineering components enable at least a partial switch to the non-flammable and environmentally neutral gases CO2 and nitrogen. Your optimization potential ,Improved mechanical product properties ,Lower foam density ,Replacement of hydrocarbon blowing agents with CO2 and nitrogen ,Increased line throughput

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix specializes in demanding cooling and heat exchanger tasks such as cooling and heating of viscous or decomposition-sensitive media / plastic melts. The Promix P1 heat exchanger is the unique combination of a very efficient static mixer and a powerful cooler. The novel patented technology opens up completely new process engineering possibilities in the cooling and heating of plastic melts and other viscous fluids. The simultaneous mixing and cooling processes in the P1 allow for very efficient cooling and heating without the formation of deposits or the risk of product decomposition. Advantages Promix P1 heat exchanger Very efficient cooling of polymer melts close to the solidification point Precise temperature control and uniform temperature distribution at the outlet Very robust construction Extremely gentle cooling and heating of residence time critical fluids Unique self-cleaning behavior Reliably scalable from laboratory test to production scale Test options

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The simple and compact design of this miniature PE converter with fixed switch-on pressure of 0.8 bar allows its use in various applications such as medical technology, dental treatment units, robotics, analysis systems, process and safety engineering. Easy mounting and high functional reliability are other advantages. By using silver contacts a long lifetime can be ensured even at high switching frequencies. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The simple and compact design of this miniature PE converter with fixed switch-on pressure of 0.8 bar allows its use in various applications such as medical technology, dental treatment units, robotics, analysis systems, process and safety engineering. Easy mounting and high functional reliability are other advantages. By using silver contacts a long lifetime can be ensured even at high switching frequencies. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Dynamic Spur Gearboxes MS-Graessner produces customer-specific spur gearboxes of a helical or straight-toothed design. The design of the toothing is carried out using KISSsoft and our own design and calculation programs. In addition to the provision of technical support and advice to our customers, we also take over the entire engineering process. By working closely together with our customers, we guarantee the development and production of the optimum drive solution in each case. Advantages: economical production simple mechanical movement and power transmission high level of efficiency high running smoothness high axial and radial loads low circumferential backlash broad range of applications long service life

Request for a quote

FLOTTWEG SE

Germany

Flottweg Technology serves over 1000 applications worldwide. Each of these engineering processes are as individual as our Z series decanter centrifuges. From the food to the pharmaceutical industry to the processing of by-products - so specific, individual and optimized, our Z series can meet many challenges with flying colors. Hygienic design, for our customers where cleanliness matters, can be guaranteed in every machine. Special ATEX protection ensures safety and our own Simp Drive® drive system make the technological performance perfect.

Request for a quoteResults for

Process engineering - Import exportNumber of results

130 ProductsCountries

Company type

Category

- Valves for pneumatic equipment (9)

- Pumps (6)

- Ceramic, components - electric (4)

- Gas detectors (4)

- Heat exchangers (3)

- Mechanical engineering - custom work (3)

- Plastics - machines and material for industry (3)

- Tanks, metal (3)

- Additives for plastics industry (2)

- Bar code scanners (2)

- Ceramics, industrial (2)

- Import-export - mechanical engineering (2)

- Pneumatic system components (2)

- Pressure regulators (2)

- Sensors (2)

- Tubs and vats, plastic (2)

- Water extraction - systems and equipment (2)

- 3D scanner (1)

- Blades and knives, industrial (1)

- Blades for saws and cutting machines (1)