- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure vessels

Results for

Pressure vessels - Import export

NC MANUFACTURING AND ENGINEERING

Turkey

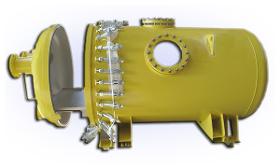

We are specialized to design and fabricate carbon, stainless or exotic steel pressure vessels mainly for oil&gas, petrochemical and power industries in accordance with ASME Sec VIII Div.1 and EN Norms with CE mark. Most of the industrial processes need to store fluids and materials of different kinds and with different purposes.

Request for a quote

NOVELTY STEEL

Turkey

A chemical reactor functions as an enclosed vessel where chemical reactions occur. It's crucial for process designers to ensure the reaction proceeds efficiently toward the desired product, maximizing yield while minimizing costs associated with procurement and operation. Operational expenses encompass factors like energy input and disposal, raw material costs, labor, and other associated charges. Typically, reactants and products within the reactor are in fluid form, either gases or liquids. Continuous reactors maintain a constant operational state, while batch reactors undergo transient operation. Transient operation occurs when a reactor is activated for the first time or following a shutdown, with critical process variables fluctuating over time.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The filter bag housings of FTJ are characterized by robustness, corrosion resistance and their practical design. The pressure vessels have an inlet and an outlet and are easy to operate.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The filter bag housings of FTJ are characterized by robustness, corrosion resistance and their practical design. The pressure vessels have an inlet and an outlet and are easy to operate.

Request for a quote

KASAG SWISS AG

Switzerland

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quote

KASAG SWISS AG

Switzerland

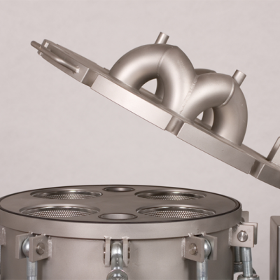

Pharmaceutical and biotech apparatuses are calculated and manufactured according to your requirements. Stainless steel and special materials are used in the production. After that, the products are grinded, electropolished and tested using non-destructive testing methods, such as ferrite measurements, used for the determination of the ferrite content, or by using the riboflavin test to measure total discharge and CIP/SIP capability. All materials, methods and processes used have been documented in full in detailed QA documents and can be tracked at any time. You can depend on KASAG.

Request for a quote

KASAG SWISS AG

Switzerland

Pressure vessels/containers and reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

KASAG SWISS AG

Switzerland

You now operate in an environment where production safety and perfect product quality have top-most priority. You must be able to place unlimited trust in your partners and to demand everything you need. With KASAG as your partner in design, engineering and production of apparatuses, pressure vessels, pressure containers, reactors, heat exchangers, modules and plants for global use, you are on the safe side. Core competences of KASAG: Design, calculation, construction according to diverse regulations, pressure equipment approvals, such as PED (EN13445, AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Manufacturing permits and knowhow for the delivery of pressurised containers, apparatuses, plants to almost all the countries in the world. Welding of stainless steel and special materials such as Hastelloy, Inconel, Duplex Comprehensive spectrum of non-destructive tests Surfaces that meet the highest standards

Request for a quote

KASAG SWISS AG

Switzerland

Reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

KASAG SWISS AG

Switzerland

Pressure vessels, reactors, Pharmaceutical and biotech pressure vessles, Process containers, storage tanks, Modules, components, plants, High-pressure apparatuses,Heat exchangers, vaporisers, condensers, Cryo pressure vessels, technologies Nuclear technology, Vacuum chambers, vacuum apparatuses, Columns, according to PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Pharmaceutical and biotech apparatuses are calculated and manufactured according to your requirements. Stainless steel and special materials are used in the production. After that, the products are grinded, electropolished and tested using non-destructive testing methods, such as ferrite measurements, used for the determination of the ferrite content, or by using the riboflavin test to measure total discharge and CIP/SIP capability. All materials, methods and processes used have been documented in full in detailed QA documents and can be tracked at any time. You can depend on KASAG.

Request for a quote

NOVELTY STEEL

Turkey

A pressure vessel is defined as a container with a pressure differential between inside and outside. The inside pressure is usually higher than the outside, except for some isolated situations. The fluid inside the vessel may undergo a change in state as in the case of steam boilers, or may combine with other reagents as in the case of a chemical reactor. Pressure vessels often have a combination of high pressures together with high temperatures, and in some cases flammable fluids or highly radioactive materials. Pressure vessels are used in a number of industries; for example, the power generation industry for fossil and nuclear power, the petrochemical industry for storing and processing crude petroleum oil in tank farms as well as storing gasoline in service stations, and the chemical industry (in chemical reactors) to name but a few.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The filter bag housings of FTJ are characterized by robustness, corrosion resistance and their practical design. The pressure vessels have an inlet and an outlet and are easy to operate.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The filter bag housings of FTJ are characterized by robustness, corrosion resistance and their practical design. The pressure vessels have an inlet and an outlet and are easy to operate.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

The filter bag housings of FTJ are characterized by robustness, corrosion resistance and their practical design. The pressure vessels have an inlet and an outlet and are easy to operate.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Pressure vessel is used (according to site function) for fluid storage, steam condensation, level measurement… Construction code: NF EN 13480, RCC-M, ASME, CODAP SPM capability: DN50 to DN400 Raw material: Stainless steel (304L, 316L…) Carbon steel (P265GH, 16Mo3, 13CrMo4-5…)

Request for a quote

GEO TEKNO LTD. CO.

Turkey

These tanks, which have wide application areas in different industries, can increase efficiency and ensure operational safety with the right choices. When purchasing a pressure tank, you should carefully consider your process requirements, paying attention to material quality, design features and safety standards. As GEO Tekno, with over 25 years of experience, we can help you select the pressure tanks you need and provide you with the most suitable solutions through our experienced design and manufacturing departments. If you need a pressure tank for your process, all you have to do is to contact us. Do not hesitate to contact us for your questions. Choose our certified pressure tanks to maximize your process performance!

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc provides plug-and-play longitudinal seam welding machine for tubes, cylinders, vacuum components, water tanks, cones, flat sheets, etc. Advantages 1. Servo motor drive carriage and double linear guide way provides great precision of 0.05mm accuracy (0.002”). Motion speed reach to 2-16,000mm/min (1~640ipm). 2. Mandrel adopts with our special design copper backing-bar and copper clamper to dissipate heat quickly. 3.Strong machine structure provides large working capacity from thickness 0.1 to 10mm 4. Smart control box, you can get started quicker than you think with it. 5. High accuracy motion for laser welding standard. Welding process: All weldable metals by TIG, MIG, Plasma, Submerged arc welding and laser welding. *CE conformity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

JOSEF JASPER GMBH & CO. KG

Germany

We manufacture pressure vessels and process engineering apparatus from steel, stainless steel and aluminium. The design, manufacturing and acceptance comply with the common national and international regulations.

Request for a quote

TECHNOSYSTEM ENGINEERING SPLTD

Bulgaria

Vertical or horizontal compressed air storage tanks and reservoirs made of carbon or stainless still with a maximum with a capacity between 150l and 160 000l. The maximum working pressure depends on customers specifications and it ranges from 8 bar to 40 bar. The vessels are equipped with drain ports on the bottom to remove condensation and can be supplied with mounting plate to secure motors, pumps and other components.

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to prove the quality of the fluid-carrying parts, all hoses, pipes, pressure vessels and other components are put under pressure until they burst. The process is precisely measured and documented in order to optimally design the components for specific applications.

Request for a quote

NOVELTY STEEL

Turkey

Stainless steel is an alloy of steel with chromium content that is a better resistant to rusting and corrosion compared to carbon steel. For storing corrosive chemicals and liquids, often traditional coatings of carbon steel does not offer enough protection. For such material, stainless steel tanks offer more durable and long lasting storage. Novelty Steel is an experienced fabricator of steel tanks. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the stainless steel tanks are: * Fixed-roof tanks * External floating roof tanks * Internal floating roof tanks * Domed external floating roof tanks * Horizontal tanks * Pressure tanks * Variable vapor space tanks * LNG (Liquefied Natural Gas) tanks

Request for a quote

KASAG SWISS AG

Switzerland

Are you using pressure vessels, apparatuses, pressure containers that are subject to the inspection cycles of the regulatory authorities? Would you like to have our advance expertise on the technical updates? Do you have problems with the cleaning of apparatuses, containers? Are you unsure about the technical details of the bought-in containers, apparatuses, and would you like them checked? We are experts in apparatus and pressure vessel construction and have comprehensive knowhow of the pressure equipment directive. For control, testing KASAG offers a wide range of non-destructive testing methods. Please get in touch with us, and our KASAG experts will be glad to offer you expertise.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

EN 10028-2 Unalloyed and Alloyed Heat Resistant Steels (P 235/265/355 GH, 16 Mo3, 13 CrMo4-5, 13CrMoSi5-5, 10CrMo9-10...) EN 10028-3 Weldable Normalized Fine Grain Steels (P275/355/460 N/NH/NL1/NL2) EN 10028-4 Ni-Alloyed Steels with Specified Low-Temperature Properties (13MnNi6-3, 12Ni14, X12Ni5, X8Ni9, X7Ni9…) EN 10028-5 Thermomechanical Rolled Fine Grain Structural Steels (P 355/460 M/ML…) EN 10028-6 Quenched / Tempered Fine Grain Structural Steels (P 355-690 Q/QH/QL)

Request for a quoteResults for

Pressure vessels - Import exportNumber of results

167 ProductsCountries

Category

- Oiling - machines and systems (24)

- Chemical and pharmaceutical industry - machinery and equipment (12)

- Gas and oil - exploitation (12)

- Mechanical engineering - custom work (10)

- Supply vessels (6)

- Filtering equipment and supplies (5)

- Pipe and tube fittings - ferrous metal (5)

- Industrial piping (4)

- Tanks, metal (4)

- Cold rolled sections (3)

- Biotechnologies (2)

- Heat exchangers (2)

- Packing and packaging - machinery and equipment (2)

- Pipes and tubes, stainless steel (2)

- Storage tanks (2)

- Welding, electric - equipment and supplies (2)

- Air conditioning, aeration and ventilation equipment (1)

- Air-conditioning systems, vehicles (1)

- Autoclaves (1)

- Bakery and confectionery industry - machinery and equipment (1)