- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses for keying

Results for

Presses for keying - Import export

REFLOACTIVE LTD

Poland

By pressing the LED key ring that lights up the inside of the bag, you will certainly find them.

Request for a quote

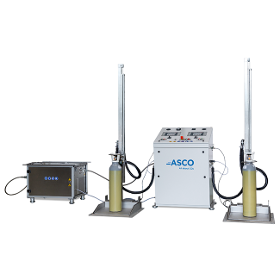

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quote

PPS (PRESSURE PROFILE SYSTEMS)

United Kingdom

The Industrial TactArray is a flat sensor that can capture and map pressure distribution in even the most extreme conditions. Constructed from high-quality Kapton or Polyimide, the Industrial TactArray can pressure distribution of up to 700 psi and in temperatures between -40° C and 200° C. This system is best suited for use in applications requiring tactile sensors that can withstand extremely high temperatures and pressures—like heat presses, brake pads, and nip rollers. Key Features High-resolution sensor arrays can measure pressure distribution at levels of up to 700 psi and retain performance characteristics in temperatures between -40° C and 200° C Real-time thermal compensation ensures accurate measurements even under changing temperature conditions Ultra-thin construction, 0.3 mm thick, and high-resolution sensing elements Can accommodate moderate flexing and bending Available in multiple sizes and configurations Chameleon Visualization Software included

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our open-die forging presses play an important part among the forming presses. Siempelkamp supplies complete open-die forging presses equipped with manipulators and ancillary equipment such as lifting turntables and quite a number of additional components. Our presses operate reliably, fast and precisely, operating at pressing forces between 10 and 160 MN. The range of presses available comprise push-down or pull-down designs, two- or fourcolumn designs with oil-hydraulic or water-hydraulic drives. High-stroke frequency contributes to the eciency of these presses. Our customers produce bars, discs, rings, and anges from materials such as steel, high-alloy steel, nickel-based alloys, titanium, and aluminium on these presses. They prefer to order turn-key plants including integrated manipulators, turntable, die magazine, and die-changing system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Presses for keying - Import exportNumber of results

4 ProductsCompany type