- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press feed

Results for

Press feed - Import export

ROLLON GMBH

Germany

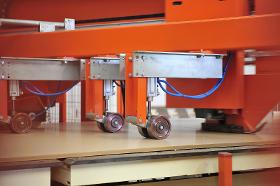

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder. With the EKZ cardboard shredder and FKZ paperboard shredder, ERDWICH’s two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, ERDWICH can always offer you a perfect solution tailored to your requirements.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

These displacement sensors are potentiometric displacement sensors used for direct measurement, testing and monitoring of mechanical displacements. The spring-loaded control rod eliminates the need of coupling with the measurement object. A prerequisite for a very long life duration of the devices is a parallel alignment of the motion direction of the measurement object and the rod. Areas of application are: Displacement on: —Electromagnets —Hydraulic cylinders —Switches and buttons Measurements of: —Deformation —Bending —Press-fits —Feed strokes Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. FEATURES: —Measurement ranges: 0 ... 10 mm to 0 ... 150 mm —Non-linearity up to 0.05 % F.S. —Resolution 0.01 mm —Follower roll on request —Optional with internal spring

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The ROPP capper is the automatic capping machine which is designed to tighten pilfer proof cap for wine bottles, olive oil bottles, drinks bottles etc. It is suitable for φ12-55mm bottle caps (Equipment can be customized according to lid diameter). The automatic operation helps you save labor and reduce production error. The capping machine is a suitable equipment for roll-press-sealing the aluminum caps for the plastic bottle, pet bottle, as well as glass bottle. It processes the screw-press capping for the bottle under the rolling press from hobs, automatically feeding bottle, caps, removing the reverse caps. The capped bottle favors the characteristics like the stable capping effect, convenient uncapping, so that it function as conterfeit and anti-theft.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Robust and extremely low maintenance Optimal access All-round bundle guide Integrated safety concept ASLF 'Anti-Strap-Loss-Function' Constant strap control Pusher (bundle accelerator and bounce back function) Strap width 5 - 9 mm, adjustable Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp Additional operating buttons, opposite to terminal (Start/Stop/Emergency Stop) DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Upstream and downstream interlocks EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' OPTIONAL: Stacker adapter for existing stacker Bundle stops, no contact with bundle when clearing the bundle, with quick adjustment Bundle press Protection covers at feed and discharge side, hinged Lateral bundle guide, adjustable Side...

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to its high resolution also when measuring long distances, linear displacement measurements up to 900 mm can be carried out. Conversions between rotatory and translation movements through ball screws, wire or cord connections and so on are not necessary for direct displacement measurement. Application fields include: —Electromagnets —Deformations - bending —Pneumatic cylinders —Length tolerances —Press-insertions (longitudinal press-fits) —Feed strokes —Machine hubs —Punch, knee lever or extruder distances —Hydraulic cylinders Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The rod is guided in a low-play floating frontal bearing. This absorbs small angular and parallel displacements.

Request for a quote

SACFORM/AGMLINE

Turkey

As SACFORM /AGMline, Our Goal with Our Compact Press Feeding Systems Is to Minimize the Space Need, For Our Customersto Manufacture Without Compromising the Production Quality.

Request for a quote

SACFORM/AGMLINE

Turkey

As SACFORM /AGMline, Our Goal with Our Compact Press Feeding Systems is To Minimize the Space Need, For Our Customers To Manufacture Without Compromising The Production Quality

Request for a quote

SACFORM/AGMLINE

Turkey

As SACFORM /AGMline, Our Goal with Our Compact Press Feeding Systems Is to Minimize the Space Need, For Our Customers to Manufacture Without Compromising the Production Quality.

Request for a quote

TECHNIC MACHINES

Turkey

Our compact coil feeder and straightener machine is for custom solutions on press feeding equipment’s results with minimum necessary space solution. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our compact coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system and as single machine body for coil decoiler, straightener and feeder. Also straightener feeder has single body design on our compact coil feeder machine system. We provide compact coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

Our coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system but separated or as single machine body for coil decoiler, straightener and feeder. We provide coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

The reason of using the Zig-Zag Coil Feeder Machine System is minimizing the scrap and waste during press works with the advantage of 2 axes movable feeding. The moveable 2 axes zig-zag coil feeder can easily adapt the majority presses. Our zig-zag coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on zig-zag decoiler straightener and feeder machine's press feeding solutions. Our zig -zag coil feeder is provide the minimum scrap solution for press feeding process. Zig-Zag coil decoiler, straightener and feeder machines are manufactured as synchronised machine system. We provide zig-zag coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

We offer suspended ceiling machine line which can produce the suspended ceiling with different thickness, width range production capacity and can work different raw materials. Also we design our tools for different suspended ceiling tile perforation patterns and panel types. As Lay-In, Clip-In and Lay-On suspended ceiling panels. And also we can produce our suspended ceiling tile production lines as to customer special request with until 2.000 mm width. Suspended Ceiling Machine Main Units – Press Feeding Unit – Perforation Press – Sheet Metal Cutting Unit – Conveyor Unit – Press Feeding Unit – Press for Notching and Bending So, machine units one by one as decoiler, straightener. servo feeder, press for perforation, cutting unit, conveyor, second straightener and feeder , press for bending and notching.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener machine for having perfect straightening results and without damage on sheet metal surface. Our coil straightener machines provide to have working possibility with high speed and precision sheet metal straightening results during press feeding. We have as alternative for coil straightener machine standard models. And we design and provide for different request specific coil straightener machines. We supply our coil straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener machine solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNIC MACHINES

Turkey

We design our coil straightener feeder machine with compact single body and for working precision feeding and without damage on sheet metal surface. Our coil straightener feeder machines provide to have working possibility with high speed and precision sheet metal feeding and straightening results during press feeding. We have as alternative for coil straightener feeder machine standard models. And we design and provide for different request specific coil feeder straightener machines. We supply our coil feeder straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener feeder machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACS Series compact system press feeding machines consist of 600 and 1600 coil width, 2 and 10 mm of sheet metal thickness, between 6.000 and 15.000 kilograms of coil weight capacity feeder, straightener and decoiler. 11-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACZ series compact servo feeder lines which have 600 and 1600 mm of coil width, between 2 and 10 mm thickness and 15.000 kilograms capacity is used as a compact press feeding machine. Our compact system servo feeder machines can process different kinds of materials like aluminum and other soft alloys, hot or cold foliated materials, carbon and stainless steel, high integrity materials and lamination steel. 11-Roller Compact Coil Servo Feeder System Components Hydraulic Decoiler Hydraulic Coil Car Hydraulic Inner Tightening and Unloading Automatic Coil Centering Feature Snubber and Upper Arm Coil Guidance Platform and Peeler Feature

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

ADS7 series 7-roller straightener servo feeder models work between 300 and 1600 mm of width and 0,5 and 4 mm of thickness. All of our 7-roller straightener servo machines utilize the piloting system and pinch rollers work synchronized with the straightener rollers. Bosporas produces 7-roller Model with static body and in accordance with CE Regulations. Our straightener servo feeders enable high performance automatic feeding to the presses. Servo feeder and straightener are merged and used in the same group. The practice of our models’ feeding system is easy to set up and to control. The angle between the feeder and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. Feeds the sheet metal in an automated cycle, pre-programmed speed and high delicacy.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient. THE RUBBERIZED FILTER PRESS OF MSE AS PROTECTIVE MEASURES AGAINST AGGRESSIVE SUSPENSIONS In a complex process, the load-bearing filter press components are coated with a layer of 3mm thick plastic. In the case of the rubberised filter press, the hydraulic stands, feed stand, pressure plate and supporting beams are hard rubberised and the smaller components are made of polypropylene. It is also possible to rubberise only the components in contact with the product, such as the feed stand and the pressure plate. The composition of the rubber coating depends on the special surface requirements of our customers.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE Filterpressen® offers a wide range of filter presses with sidebar technology suitable for both standard and medium duty and for heavy-duty performance levels. Maximum flexibility is provided by choosing between simple manual to fully automated MSE filter press designs. MSE chamber filter presses are upgradable in terms of modules and features and can be customized to your specific needs and requirements. HIGH PERFORMANCE AND HIGH DEGREE OF CONFIGURATION FOR YOUR CHAMBER FILTER PRESS The chamber filter press can be configured as required depending on the series. Taking different influencing factors into account, chamber filter presses achieve a solids content in the filter cake from 30 to over 50 percent. The intelligent filtration principle leads to immense cost savings in the waste water sector, for example. The operation of the chamber filter press is designed for a feed pressure of up to 15 bar in order to successfully filter even the finest particles.

Request for a quote

EMG PRESSE ETS LONG SAS

France

On request, we can fit your press with a complete feeding line set, delivered with the press and ready to work. decoiler straightener feeder, cutter

Request for a quoteResults for

Press feed - Import exportNumber of results

39 ProductsCompany type

Category

- Metal straightening machines (8)

- Cutting - machine tools (5)

- Industrial cutting machine tools (5)

- Mechanical surface treatment - machinery (3)

- Metal industrial presses (3)

- Drainage systems and equipment (2)

- Sensors (2)

- Industrial robots (1)

- Internal transport systems (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Oils, cooking - machinery and equipment (1)

- Water retreatment - equipment and installations (1)

- Wood veneer - machinery and equipment (1)