- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press brake bending

Results for

Press brake bending - Import export

SINOP SMP

Czech Rep.

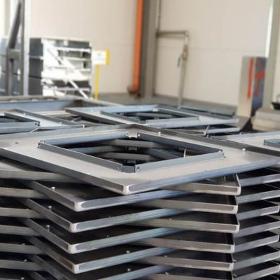

Die Bending with Press Brake Custom manufacturing as well as large volume production Software simulation of bending feasibility CNC programming of press brakes from office “Z” bend, flattened hems and radius bends Bending flexibility thanks to 6-axis backgauge Maximal bending length 3000 m, maximal sheet thickness 10 mm

Request for a quote

OREMUS S.R.O.

Czech Rep.

The basis of efficient welding process is precision bending on modern machines. In our case, TruBend 8400 Press Brake offers a maximum bending width up to 4000 mm with pressure of a respectable 400 tons.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide sheet metal bending services. Our sheet bending is carried out with the help of edge presses with very high accuracy, long-series elements can be implemented through an automated device that supports the work of qualified operators. Material possibilities: • we have three press brakes that enable sheet bending at a length of 3000 mm. • The maximum bending length is 3000 mm • The maximum thickness of bending over a length of 1000mm – 5mm and 8mm • Pressure – 125 and 135 tons • With Laser head for cutting material at an angle – 3D Please send your inquiry to the following e-mail address: biuro@web-elektron.pl

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Proper bending of aluminium and magnesium requires specific knowledge of the material. The phase in the process in which the material is bent is also crucial to the final result, right after pressing or only after hardening, for example. There are many techniques for bending, such as roll forming, press (brake) bending, swivel bending, deep drawing, stretch forming, and 3D bending.

Request for a quote

FUSED MACHINERY

Belgium

Excellent press brake with 650T bending force and 6200 bending length. This machine is in very good condition, immediately available and can be inspected under power. Extensive set of tooling available as well. More information on request.

Request for a quote

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quote

MAHERAS LTD.

Bulgaria

We have hydraulic press brake for flatness bending.

Request for a quote

LVD

Belgium

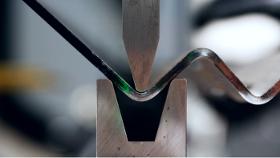

Our extensive range of high quality press brake tooling meets your every bending need. A complete line of standard press brake tooling is available for machines from 120 to 30000 kN. Single, multiple and adjustable V-dies are also offered. LVD’s patented STONE radius V-dies employ an innovative design that assures accurate bend angles along the entire bend length. Vertical removable style tooling makes tool changeover quick and easy. Specialized tooling is designed to withstand extremely high forces and rugged production conditions. All LVD-tools are hardened to 56 HRc. KEY FEATURES Exclusive STONE radius V-dies Range of vertical removable tooling in single tools or complete tooling sets Long production life High quality, wear-resistant and durable PRODUCTIVITY-ENHANCING OPTIONS Specialized tooling for custom applications MODELS Complete tooling sets Special tooling

Request for a quote

FOXLASER

Bulgaria

Sheet metal bending The two key words when it comes to sheet metal bending are accuracy and quality. FoxLaser guarantees both, thanks to the latest generation of digital, hydraulic press brakes from the Japanese company AMADA. The 7-axis control allows for a very fast process in the production of test parts and prototypes of bent sheet metal, as well as perfect repeatability of the bends in long series. FoxLaser owns nine press brakes for bending, three of which of a brand-new generation, with the option of external programming. Combined with AMADA's specialized BendCam software, they speed up and improve the prototyping process immensely. We are proud owners of a large-sized press brake machine, which allows bending of sheet metal parts up to 4000 mm and also one with a capacity of 320 t by 3000 mm. Additionally, we have manual sheet metal bending machines, press brakes and three-shaft rounds (for cylindrical and conical molding).

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Abkant (Press Brake or Bending Press) machines are a type of bending press. They are used in operations such as metal bending and metal curling. Nowadays, many computer-controlled Abkant machines are available. These machines have accelerated the production in terms of both form utility and time saving. With Abkant curling cylindrical, conical, elliptical and oval shapes can be provided. The length, thickness and type of the material (stainless, aluminum, steel sheet, etc.) to be curled are important in the choice of Akbant machine. Akbant machines have individual molds and specific radiuses for various bending operations. The angle calculation of the sheet while performing bending operation using Abkant machine is a skill that requires expertise. Otherwise, bended lengths may not be at the desired sizes. As Ramazan Aycan Inc., we provide you with bending services with our hydraulic and electro servo Abkant machines.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

STAR high quality bending film / folding foil is a high quality product, which offers best protection for parts and press brake tools on nearly every press brake machine. It is tested and developed under most difficult conditions. Test our high quality bending film / folding foil / antiscratch film and see, how you can protect your press brake tools, your bended parts and save money by saving time and avoiding extra work! Avoid following problems : Scratches imprints marks other problems caused by the direct contact from press brake tool and part extra work to clean the part after having scratches, imprints or marks scratches on press brake tools

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECITOOLS SRLS

Italy

Special tools for customized applications and parts including forming, several bends in one stroke, controlled deformation, coining and stamping etc. The special press brake tools could be supplied for any press brake and system. We can also deliver as specials press brake tools for American style tools, LVD system, EHT system, COLLY - AJIAL system, HACO system and many others.

Request for a quote

METALUX

North Macedonia

At our company, we take pride in offering CNC bending services that adhere to the highest standards of quality and precision, utilizing Press Brake's advanced bending technologies. We provide a wide range of CNC bending operations, tailored to meet each customer's specific preferences and needs. Quality is of paramount importance to us, and we are committed to maintaining this principle throughout all our CNC bending operations. To achieve exceptional results that meet our stringent quality standards, we rely on the industry's best-performing machines – Press Brake bending technologies. As your trusted OEM partner, we meet production demands with an agile approach and strict quality control, ensuring precision in every piece. Contact us now to discuss your needs and partner in shaping a brighter future for your sheet metal endeavors.

Request for a quote

HASSAS MAKINA METAL PROCESSING

Turkey

provide laser cutting, plasma cutting, tube laser cutting, optical cutting, press brakes, tube bending, cnc tube processing and guillotine cutting processes within our own facility

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Beyeler (Euro-A, RF-A, R, S), Edwards Pearson, Safan, Bystronic, Beyeler etc. We supply solid pieces 100, 500, 1000 mm; section set (cutted) 1100 mm and complete sets for the full length of your press brake. Dies could be used with Trumpf-WILA system. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Hammerle, Durma, EHT, Finn-Power, Jordi, Gizelis, LVD, Trumpf, Prima Power, RICO PRCN, Safan-Darley, STR, Ursviken etc. We supply solid pieces 100, 200, 300, 500 mm; section set (cutted) 550 mm and complete sets for the full length of your press brake according to the customized pieces or the same as original tooling. For TRUMPF-WILA press brake tools we can offer 100% compatible tools as original. Dies could be used with Beyeler-Bystronic system. Any punches for Trumpf-Wila with low weight could be equipped with push buttons for quick frontal extraction. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Accurl, Adira, AM Machinery, Amada, Augusta, Axial, Baykal, Boschert, Bystronic, CMU, CoastOne, Colgar, Colly, Gasparini, Gilardi, Gizelis, Guifil, Dener Makina, Deratech, Durma, Edward Pearson, Ermaksan, Euromac, Femas, Fratelli Farina, GADE, Gasparini, Gecko, HACO (Atlantic), Hammerle, Hesse, Hezinger, Hilalsan, IMAL, Inanlar, Ironmac, ITEK, Jean Perrot, Jordi, KAAST, Karmet, Kingsland, Knuth, LAG, Mecos, MVD, Muratec, Nargesa, OMAG, Peliant, Rico, Salvagnini, Schiavi, SMD, STR, Tabama, TCI etc. We supply solid pieces 415, 835 mm; section set (cutted) 805 mm and complete sets for the full length of your press brake. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

We offer special adjustable bending dies for various press brakes with medium and high tonnage for bending of big thickness sheet metal. These dies are great solution for the possibility to replace several set of standard dies and adjust die opening directly on the machine. Models available: V25-125; V65-180; V120-300; V150-400. In addition there are options of semi-automatic and automatic adjustment system. We are able to study the project for the possibility to offer together with adjustable dies all necessary punches as complete solution.

Request for a quoteResults for

Press brake bending - Import exportNumber of results

28 ProductsCountries

Category

- Bending machine tools (7)

- Bending - steels and metals (5)

- Industrial sheet metal work (4)

- Laser - cutting and welding machines (2)

- Milling - steels and metals (2)

- Brakes, servo-brakes and accessories (1)

- Compactors and crushers (1)

- Construction, industrial - contractors (1)

- Cutting - steels and metals (1)

- Motor mechanics - hand tools, non power (1)

- Punching machines, plastic (1)

- Steel & Metals (1)

- Tempering, metals - machinery and installations (1)

- Welding work - steels and metal (1)