- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press brake accessories

Results for

Press brake accessories - Import export

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down. Following to this the braking resistor converts the stop energy into heat. Electrical drive systems are being used more and more on ships, oil rigs, crane barges and offshore vessels of all types. An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy. The Braking Resistor Units from Klöpper Therm are designed according to specific applications.

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

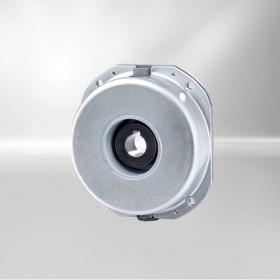

The Active Brake Line includes DC single-disc brakes, in which the action of force of an electromagnetic field (electromagnetically closing) is used to generate the braking force. The Active Brake Line is characterized by a secure, residual moment-free lifting in any position, and by a backlash-free transfer of the braking torque. Throughout their complete service life, they require little or no maintenance.

Request for a quote

LVD

Belgium

PPEB Series press brakes offer high precision and flexibility. Equipped with state-of-the-art hydraulics and electronics and offered in multi-axis configurations, the PPEB can tackle bending applications from simple to complex, efficiently and cost effectively. LVD’s intelligent bend database is used to automatically optimize each part program to eliminate trial bending and reduce the time it takes to bend a quality part. KEY FEATURES TOUCH-B touch screen graphical user interface control is intuitive and simple to use Bending parameters automatically controlled by LVD's unique 'intelligent' learning database 2D & 3D color graphics simulate part creation and display material handling sequencing CNC crowning V-axis standard for models over 2 meters Press brakes up to 400 ton/4 meter are designed and built using a welded one-piece frame for machine precision Enhanced Energy Reduction System (ERS) Turbo hydraulics (standard on 220-ton modeland higher) PERFORMANCE-ENHANCING OPTIONS

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Electromagnetic clutches and brakes of Kendrion (Aerzen) GmbH are easy to install and integrate into the machinery concept/layout with no setting up or running in. Kendrion offers a combination fitted on a hollow shaft for applications where clutches and brakes work together. The units are based on the successful magneta components. They are fitted on a through shaft. The unit is fixed using simply two screws and is ready for operation then. Electromagnetic clutches and electromagnetic brakes from Kenrion (Aerzen) GmbH transmit the drive torque and braking torque frictionally in dry running conditions. If a DC current is applied, the torque is transferred without backlash. Residual torque free ventilation in a de-energised state is ensured by the prestressed annular spring of the armature section. The clutches and brakes are suitable for every mounting position and require almost no maintenance.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Elevation Line includes both DC spring-pressure single-disc brakes as well as spring-pressure double-disc brakes which comply with EN 81 (Safety Regulations Concerning the Design and Installation of Elevators). Integrated micro-switches allow for remote inquiry of the brake condition (armature position, wear, armature bearing). Owing to the patented safety concept, the otherwise mandatory testing of the dual-circuit braking system of the spring-pressure brake at the approval of the elevator system can be dropped. The brake can be used in places where short construction lengths with respective system components like motor, gear and brake must be realized. The Elevation Line is primarily used for elevators, but can be used wherever the brake must meet demanding safety requirements. Electromagnetic spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The EEX Line includes spring-pressure single-disc brakes provided with explosion protection for explosion-hazardous areas. The spring-pressure brake with firedamp protection is suitable for underground excavations with danger of firedamp. In spring-pressure brakes with explosion protection, those parts which might ignite explosive mixtures are incorporated in a housing. If the mixture inside the housing explodes, the latter prevents a transfer of the explosion to the mixtures surrounding the housing. The brake is equipped with four thermal circuit breakers and one micro-switch. The micro-switch prevents starting against the unlifted brake. The thermal circuit breakers are series-connected with the micro-switch and interrupt the control circuit of the machine as soon as there is an inadmissibly high temperature at the brake. The brake is seawater-resistant. By means of the attached hand lifting feature, the braking effect can be manually neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Compact Line includes spring-pressure single-disc brakes that can be mounted as complete units to the motor with very little assembly work. The compact design is of advantage when limited space complicates mounting. Electromagnetically-operated spring-applied brakes build up the braking torque when the current is switched off.

Request for a quote

ENGIFIELD - MECHANICAL POWER TRANSMISSION

Spain

Power off electromagnetic brake - spring applied (holding) is design to stop the movement when the electricity is off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Classic Line includes DC spring-pressure single-disc and multi-disc brakes which, due to their robust design and the variable connection technology, meet the requirements of demanding applications. Electromagnetically-operated spring-applied brakes build up the braking torque when the current is switched off and the electromagnetic force is therefore neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The High Torque series combines the well-known properties of permanent magnet brakes - Due to a re-design of the magnetic circuit, it features further advantages such as a higher torque at identical size and power consumption, high torque constancy throughout the complete service life and an extended temperature range. The High Torque brake is designed to operate dry. The force generated by a permanent magnetic field is utilised to produce the braking effect. To neutralise the braking action, the magnetic flux of the permanent magnets is cancelled by an alternate electromagnetic field (electromagnetically released system). The zero backlash connection between the armature and flange hub ensures zero backlash transmission of the brake torque to the machine shaft (e.g. motor shaft) and reliable release of the High Torque brake with zero residual torque. Thanks to these features, High Torque brakes are ideal for servo motor applications.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The PM Line includes permanent magnet brakes in which the braking force is generated by a permanent magnetic field. The brake thus works in a de-energized condition and fulfill the following functions: Holding, positioning and emergency stop. The neutralization of the braking force is effected by the counteracting electric field, granting a high degree of security, even in the case of power failure. Permanent magnet brakes are characterized by a secure, residual-moment-free lifting in any position, and by a backlash-free transfer of the braking torque. Therefore, they are ideal for servo motor applications.

Request for a quote

ŞAHINLER IVECO AUTOMOTIVE AND SPARE PARTS CO. INC.

Turkey

8582290 BRAKE DISC IVECO Daily Our portfolio includes OVER 30000 items for newest iterations / revisions of Iveco Eurocargo, Iveco Daily, Iveco Stralis, Iveco Astra and Magirus. Also parts for older but still being used models. Please contact us and ask any further information regarding the specifications and quotations of the products.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Slim Line includes spring-pressure single-disc brakes for brake discs mounted non-positive on the shafts to be retarded. The brake disc, which is permanently connected to the shaft, can be designed as a motor fan. Owing to the single-disc brake design, SLIM LINE brakes are particularly flat. Based on the working principle, residue-free lifting is achieved. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The VARIO LINE includes DC spring-pressure single-disc brakes, which can be matched to the individual application due to a wide range of variants. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off. By means of the electromagnetic force or an additionally mounted hand lifting device, the braking effect can be neutralized. Fitting dimensions and the grading of the type series of the VARIO LINE are matched to IEC motors.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Kendrion (Aerzen) Mini Permanent magnet brakes open electromagnetically. The braking torque without backlash is generated by permanent magnets. The brakes can be installed in any position. High quality magnets ensure safe functionality. The rated torque is achieved immediately at the time of delivery without any running-in procedure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENDRION (VILLINGEN) GMBH

Germany

Electromagnetic clutches and brakes by Kendrion (Aerzen) transmit the torque and brake torque through dry running friction material. With DC voltage applied, the torque is transmitted without backlash. Using the prestressed spring of the armature, a release, free of residual torque is ensured. These clutches and brakes can be installed in any mounting position and hardly need any maintenance. Kendrion (Aerzen) offers standard clutches from 0.3 to 3.6 Nm as well as customer- and application-specific solutions up to 5 Nm.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied single-disc brakes in the Servo Line series are designed to operate dry. They can be mounted to the A-face or B-face end shield inside the servo motor. The braking action generated by the compression springs is neutralized by applying the electromagnetic principle involving generation of a magnetic field. The brakes engage in unpowered condition and release when DC voltage is applied. The brakes are equipped with a flange and firmly fastened with screws. Thanks to a specially developed and patented manufacturing method, the rated air gap tolerance can be reduced to a few hundredths of a millimetre, providing enhanced power. Moreover, the brakes have a toothed hub/friction disc connection with minimal circumferential backlash. Standard version is suitable for flange mounting and face mounting.

Request for a quote

LVD

Belgium

Our extensive range of high quality press brake tooling meets your every bending need. A complete line of standard press brake tooling is available for machines from 120 to 30000 kN. Single, multiple and adjustable V-dies are also offered. LVD’s patented STONE radius V-dies employ an innovative design that assures accurate bend angles along the entire bend length. Vertical removable style tooling makes tool changeover quick and easy. Specialized tooling is designed to withstand extremely high forces and rugged production conditions. All LVD-tools are hardened to 56 HRc. KEY FEATURES Exclusive STONE radius V-dies Range of vertical removable tooling in single tools or complete tooling sets Long production life High quality, wear-resistant and durable PRODUCTIVITY-ENHANCING OPTIONS Specialized tooling for custom applications MODELS Complete tooling sets Special tooling

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Beyeler (Euro-A, RF-A, R, S), Edwards Pearson, Safan, Bystronic, Beyeler etc. We supply solid pieces 100, 500, 1000 mm; section set (cutted) 1100 mm and complete sets for the full length of your press brake. Dies could be used with Trumpf-WILA system. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Bending film for press brake bending to protect from scratches, marks, imrints and other surface defects during bending polished materials, prepainted, grinded surfaces etc. together with die protection. Our bending film is premium quality, "Made in Germany". Could be used for bending of steel, stainless steel, aluminium alloys and any non ferrous metals and highly important for the usage in the production of decorative and prepared surface goods. The delivery program: * 0,4 x 100 mm width (length of roll 54 m) * 0,5 x 100 mm width (length of roll 45 m) * 0,8 x 100 mm width (length of roll 18 m) Width 150-200 mm ; 1,0 and 2,0 mm thickness film is available under request. The film could be used as it is with any tooling or press brake with manual positioning or usage of special holders to fix and to rotate after consume.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Hammerle, Durma, EHT, Finn-Power, Jordi, Gizelis, LVD, Trumpf, Prima Power, RICO PRCN, Safan-Darley, STR, Ursviken etc. We supply solid pieces 100, 200, 300, 500 mm; section set (cutted) 550 mm and complete sets for the full length of your press brake according to the customized pieces or the same as original tooling. For TRUMPF-WILA press brake tools we can offer 100% compatible tools as original. Dies could be used with Beyeler-Bystronic system. Any punches for Trumpf-Wila with low weight could be equipped with push buttons for quick frontal extraction. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Accurl, Adira, AM Machinery, Amada, Augusta, Axial, Baykal, Boschert, Bystronic, CMU, CoastOne, Colgar, Colly, Gasparini, Gilardi, Gizelis, Guifil, Dener Makina, Deratech, Durma, Edward Pearson, Ermaksan, Euromac, Femas, Fratelli Farina, GADE, Gasparini, Gecko, HACO (Atlantic), Hammerle, Hesse, Hezinger, Hilalsan, IMAL, Inanlar, Ironmac, ITEK, Jean Perrot, Jordi, KAAST, Karmet, Kingsland, Knuth, LAG, Mecos, MVD, Muratec, Nargesa, OMAG, Peliant, Rico, Salvagnini, Schiavi, SMD, STR, Tabama, TCI etc. We supply solid pieces 415, 835 mm; section set (cutted) 805 mm and complete sets for the full length of your press brake. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

We offer special adjustable bending dies for various press brakes with medium and high tonnage for bending of big thickness sheet metal. These dies are great solution for the possibility to replace several set of standard dies and adjust die opening directly on the machine. Models available: V25-125; V65-180; V120-300; V150-400. In addition there are options of semi-automatic and automatic adjustment system. We are able to study the project for the possibility to offer together with adjustable dies all necessary punches as complete solution.

Request for a quote

PRECITOOLS SRLS

Italy

Special tools for customized applications and parts including forming, several bends in one stroke, controlled deformation, coining and stamping etc. The special press brake tools could be supplied for any press brake and system. We can also deliver as specials press brake tools for American style tools, LVD system, EHT system, COLLY - AJIAL system, HACO system and many others.

Request for a quoteResults for

Press brake accessories - Import exportNumber of results

28 ProductsCountries