- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision strip

Results for

Precision strip - Import export

AMETEK SPECIALTY METAL PRODUCTS

United States

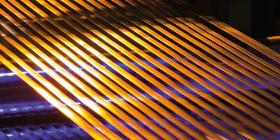

Here at Hamilton Precision Metals, we’re passionate about cold rolling metal strip in a diverse range of specialty alloys to meet your exacting specifications. Our extensive precision strip product range include stainless steel strip, nickel strip, titanium strip, copper based strip, cobalt based strip and many more alloys. We have the expertise to roll light gauge strip from 1.5 mm (.060”) down to 0.127 mm (0.005”). Broadest Range of Alloys We offer an extensive portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®,

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

CORMIFLEX® tubes are folded spiral-seam pipes made of high-grade steel precision strip. Reaching up to 350°C, their high temperature resistance is predominantly used for exhaust gas routing in passenger car, utility vehicle, RV and marine heating units. CORMIFLEX® PLUS bears additional resistance against corrosion due to salt and other aggressive agents.

Request for a quote

MICRO-EPSILON

Germany

The thicknessGAUGE O.EC is a compact inline measuring system in a stable O-frame design with an aluminum roller and an integrated control cabinet. The system is used for precise thickness measurements of plastic strips and coatings up to 3 mm material thickness and web widths up to max. 1250 mm. To obtain a cross profile of the material thickness, the sensor is traversed over the film. Keeping the sensor fixed at a particular position enables a thickness profile to be generated. Integration takes place in complete production lines, e.g., in plastics production and battery film production. The systems can be integrated into new plants or retrofitted directly into existing plants.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE sensor systems are used for precise thickness measurements of strip materials, plates and sheets up to 50 mm. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces based on an unmatched price/performance ratio. This fully assembled system comprises a stable frame on which two optical distance sensors are fixed, which detect the thickness of the measuring object according to the difference principle. The sensors are perfectly aligned to each other in terms of their mounting condition. Furthermore, thickness calibration at the factory enables high precision thickness measurements.

Request for a quote

FRANK EUROPE GMBH

Germany

ALPHA SHOWCASES - the new display generation Reflection on the essential ☑ Fully demountable ☑ optimal use of materials and components ☑ laminated glass and the patented FRANK connection system ☑ available in three sizes The innovative design is based on the patented FRANK connection technology. This makes gluing and screwing superfluous. The essential detail is the barely noticeable aluminium profile strips, which are precisely inserted into the patented edge profiling of the panes. Sealing materials, such as silicone etc. are not necessary. This facilitates assembly and ensures a long life without maintenance. The freestanding ALPHA showcase, step-in model from Frank, has won in its minimalist design international awards and convinced many directors/curators with its maximum transparency. The discreet lines express the lightness of the construction. Function and design are perfectly balanced in all simplicity. This simplicity is the highest form of perfection.

Request for a quote

BÜRKLE GMBH

Germany

At a glance • PS, white • Optionally packaged individually and sterilised • With stripper edge • For single use • Clean room manufactured (clean room class 7) • Complies with EU food requirements and FDA regulations Volumetric and dosing spoons can be used to measure small amounts of powder, granulates and liquids exactly and dose them precisely. For precise measuring, excess medium is stripped off the upper edge of the spoon. The content volume is engraved on the handle. The flat front edge of the volumetric spoon is ideal for picking up medium from the bottom of the container or for getting into the corners of the container, thus allowing for good emptying of small remaining amounts. The flat base makes it possible to set the volumetric spoon down without spilling the content. The disposable dosing spoon is suitable for use as a sample spoon for taking small sample quantities.

Request for a quote

KRANAMAX

Bulgaria

Strong and stable structures for excavation.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision re-rolled stainless steel strip products can be engineered to specific customer requirements with exceptionally short lead times. Based on our longstanding expertise, we can manufacture stainless steel strip to precise custom sizes, ultra-thin gauges and tightly controlled mechanical properties with any surface finish. We also work closely with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to produce stainless steel foils down to 1.5 microns (.000060”) thickness. Standard Alloys We manufacture stainless steel strip in a variety of chemical and mechanical properties, expertly engineered to your exacting specifications. High performance stainless steel strip material includes: Austenitic: 300 series Martensitic: 400 series Ferritic: 400 series PH Grades 17-7PH®, 17-4PH® Additional options available on request

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision C is a heat treatable Nickel-Iron Alloy used in critical diaphragm applications, such as, metal diaphragms for aerospace sensors and burst discs. The alloy composition provides a unique constant elastic modulus value over a temperature range of -50ºF to 150ºF. Precision C can be readily formed from the annealed temper. It has a work hardening rate similar to austenitic stainless steel. The material can be joined by TIG, EB, and resistance welding as well as by brazing and soft solder technique. The heat treatment of Precision C can be adjusted to produce the desired value for the thermoelastic coefficient at or near zero. The elevated strength in the heat treated temper results in low mechanical hysteresis and low drift. Available Sizes: Precision C is available from Hamilton Precision Metals as strip product in thickness from 0.0005” to 0.040” (0.0127 mm to 1.016 mm) and widths up to 8.0” (203.2 mm). The material conforms to ASM 5221 and UNS N09902.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our precision metal strip products are custom-made in biocompatible alloys for implantable medical devices that improve quality of life for patients around the world. We work in partnership with Hamilton Precision Metals to manufacture innovative metal materials that enable smaller, lighter and higher performing medical implants. Superior Titanium Strip for Implantable Medical Devices We have developed proprietary practices for the successful reduction of Titanium Grade 5 (6Al-4V) and Titanium Grade 23 Alloys (6Al-4V ELI) to thicknesses of 0.0039” (0.10mm). Our process results in a finish much superior to alternative methods of etching or grinding strips to gauge. This surface finish and gauge control translates to improvements in finished product quality as well as process controls during drawing, stamping, etching or laser cutting. These alloys are offered in the fully annealed or the as-rolled tempers.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

For more than 85 years, we have been at the forefront of supporting metallurgical and engineering advances in the medical industry. Today, our innovative materials are used by some of the largest manufacturers of implantable medical devices and technology in the world. Implantable Materials for Life-Saving Medical Applications Our precision strip and shaped wire materials are custom-engineered in biocompatible alloys and play a critical role in creating life-saving medical implants and medical devices. Precision Metal Strip for Implantable Medical Devices Tight Tolerance Custom Shaped Wire for Orthodontic Brackets Shaped Wire for Toothbrush Staples and Anchor Wire Electrolytic Copper Wire (C11000) used as Shaped Channel Wire for Superconductors in MRI Scanners We Engineer Precision Materials to Meet Your Medical Implant Needs Our range of highly customized medical-grade alloys combined with our metallurgical expertise, makes us the go-to material supplier

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability, and that’s why so many leading commercial and defense aviation programs use our high performance materials. 50 years Aerospace Expertise We have more than 50 years experience developing precision strip, wire and shaped component products for critical aerospace applications worldwide. Our aerospace portfolio includes: High Tolerance Custom Shaped Wire for Aircraft Push-Pull Controls Pfinodal® (C72900) Bearing Material for Landing Gear Bushings and Bearing Sleeves Specialty Shaped Wire for Lock Collar Tape used in Aerospace Rivets Highly Conductive Nickel Strip for Aerospace Electronic Connectors, Batteries, Heat Exchangers and Bellows. Lighter and Stronger Materials for Aircraft Performance At 35,000 feet, every detail matters. We’re dedicated to manufacturing precision, lightweight and high strength materials to enhance the performance and efficiency of aircraft worldwide.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our titanium strip portfolio includes titanium grade 23 (Ti 6Al-4V ELI) and titanium grade 5 (Ti 6Al-4V). These products are custom-made to exacting specifications and predominantly used for implantable medical devices. We also work in partnership with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to engineer titanium strip and foil in Ti Grades 1, 2, 4 and 9 down to 1.5 microns (0.000060”) thickness. Titanium Grade 23 Strip (Ti 6Al-4V ELI) Ti 6Al/4V ELI strip is used in medical implant applications owing to its excellent biocompatibility, high strength, and MRI compatibility. Titanium Grade 5 Strip (Ti 6Al-4V) Ti 6Al/4V strip has an excellent combination of strength, corrosion resistance, and fabricability. Consequently, it is used extensively in aerospace, medical, marine, and chemical processing, and surgical implants.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hamilton Precision Metals is the world leader of precision-rolled foil and ultra-light gauge strip in any alloy. This includes stainless steel foil, titanium foil, nickel foil, copper based foil, cobalt based foil, Constantan® foil, Evanohm® foil, and many other alloys. Metal foil is generally defined as strip 0.004” (0.1016 mm) and below. Cold rolling strip to these extremely thin gauges demands extensive rolling expertise to manufacture with precision and consistency. Foil in Any Alloy We offer the broadest portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®, Tightest Tolerances and Thinnest Gauges in the Industry We custom roll metal foil in nearly any alloy and specialty metal to the tightest tolerances and thinnest gauges

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our ability to process corrosion resistant, conductive and high temperature alloys enables us to engineer precision materials that are highly suited for Industrial applications. Advanced Materials for Industrial Applications The precision strip and shaped wire materials we manufacture improve product performance in critical Industrial applications including: Weld Wire Sheathing for Flux Cored Wire and Metal Core processes Nickel-Tungsten Strip (NiW) for Superconducting Substrate Material Small Engine Needle Valves Bunched Nickel Wire for Thermocouple Wire Dedicated to Meeting Your Industrial Needs At AMETEK Specialty Metal Products, we take pride in developing material solutions that match the exacting needs of our customer for their Industrial applications. With a dedicated team of full-time metallurgists, we deliver a full service from material selection to supply.

Request for a quote

JINTIAN COPPER

Germany

Main products: High-precision tin phosphor bronze strips, copper strips, brass strips and white zinc copper strips Product characteristics: Good yield strength and fatigue strength, good elastic properties, excellent processing and bending properties, good ductility, durability and corrosion resistance Applications: Electrical and electronic devices, communication technology, electrical network, hardware, construction industry, home appliances Production capacity: 104,000 tons Honorary titles: Zhejiang Famous Brand Product, China's Top 5 Copper Strip Company

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Automotive safety systems need to be reliable, accurate, and capable of saving lives. We work closely with automotive component suppliers worldwide to develop custom metal strip materials that enhance performance and safety. Precision Engineered Strip for the Automotive Industry You’ll find our strip products in many critical automotive systems in today’s vehicles including: Reed switch systems Nickel strip for EV battery connectors Electronic Connector Materials High Performance Automotive Alloys Nickel-iron compositions from 36% to 65% nickel High purity nickel Strip Spinodal alloys Safe and Efficient Automotive Material Solutions Our metallurgists engineer custom material solutions using the highest quality alloys to ensure maximum automotive performance, reliability and safety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAINLESS BAND LTD

United Kingdom

Precision strip used in the manufacture of spiral wound gaskets and other processes such as pressings. Our Bobbin wound material is extensively used in the gasket sealing industry. Bobbins can be up to 15kgs and speed up the change overs and reduce scrap loss. Our spiral wound gasket production facilitates thicknesses of 0.20mm, 0.18mm, 015mm and 0.10mm. Widths come as standard in 5.33mm, 5.0mm, 4,75mm with a minimum width of 2.50mm. The minimum order for our bobbin wound products is 20k depending on the grade ordered. All of our spiral wound gaskets can be supplied on plastic ribbon or pancake coils. Our inner ring production sizes come in 3.00mm, 4.00mm and 5.00mm thicknesses and widths of 6.50mm wide to 100mm wide. Our minimum orders for inner ring production is 50kg depending on the grade. Material can be supplied as coil or in lengths of a maximum 3 metre.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has built a reputation for first class product quality and reliability. That’s why leading defense programs use our high-performance materials. Leadership in Defense Metals We have more than 50 years of experience developing precision strip and thermal management products for critical defense applications worldwide. Our defense portfolio includes: Thermal management materials for semiconductor heatsinks Nickel strip for battery connectors High Performance Defense Alloys Molybdenum Copper (AMC) and Tungsten Copper (AWC) High purity nickel strip Trusted for Critical Defense Applications Due to their excellent thermal conductivity and controlled thermal expansion, our Molybdenum-Copper and Tungsten-Copper composites are the preferred materials for Gallium Arsenide (GaAs) and Gallium Nitride (GaN) semiconductors for the defense industry. Our heat spreader materials are trusted in sensitive applications such

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Moly Permalloy® is a Nickel-Iron-Molybdenum alloy with a magnetic permeability that makes it suitable for electrical shielding applications. The alloy can be readily formed from the annealed temper.Effective magnetic shielding is provided by annealing at 1900°F or higher. Joining is accomplished by spot welding or tungsten inert gas welding. Available Sizes: Moly Permalloy® is available from Hamilton Precision Metals as strip product from 0.0005” to 0.015” (0.0127 mm to 0.38 mm) in widths to 12.0” (304.8 mm). It is also available in foil as thin as 0.000100” (0.00254 mm) in widths of 4.0” (101.6 mm) maximum. The metal conforms to ASTM A753, Type 4 and MIL N 14411, Type 1.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Rodar® is an Iron-Nickel-Cobalt alloy with an unique linear thermal expansion coefficient. It is also stable to cryogenic temperatures. This combination of characteristics has prompted its application in electrical package sealing of glass/metal and ceramic/metal. Rodar® can be formed and deep drawn from the annealed temper. A 1/8 hard temper is optimum for heavy piercing.The material can be joined to other metals by welding, brazing, and soldering. The joint design must consider that Rodar® has a lower expansion coefficient than most other metals. Available Sizes: Rodar® is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.060” (0.0254 mm to 1.524 mm) and width up to 12.0” (304.8 mm). The material conforms to ASTM F15, AMS 7728 and UNS K94610.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Unalloyed Tantalum is supplied to ASTM F560 – R05200 composition limits. Tantalum is selected for its corrosion resistance, thermal conductivity, high melting point, and ability to form a dielectric oxide film. Tantalum is very ductile and can be readily cold formed due to a low work hardening rate. Welding can be accomplished via resistance, TIG, or electron beam methods, with care taken to protect the weld and heat affected zone from air during welding. Because of the potential for hydrogen embrittlement, Tantalum can not be used for extended service in air or other oxidizing atmospheres above 260°C unless a protective inert atmosphere or vacuum is provided. Available Sizes: Tantalum is available from Hamilton Precision Metals as strip product from 0.0005” to 0.035” (0.0127 mm to 0.889 mm) in widths up to 12.0” (304.8 mm). The material conforms to UNS R05200 and meets the requirements of ASTM F560 and ASTM B708.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Evanohm® R is a unique resistance alloy with high electrical resistivity and very low temperature coefficient of resistivity (TCR). The alloy is produced by melting and conditioning practices which result in a low level of pinholes at ultra-thin thicknesses. This combination of attributes with inherent corrosion resistance makes it suitable for a variety of strain gauge, foil heaters and airbag igniters. The alloy is supplied with 90% cold reduction which has a positive TCR of about 70 PPM/ºC. A stabilizing heat treatment (approximately 475ºC) during manufacture of finished parts adjusts the TCR to a desired value. The heat treatment virtually eliminates any drift tendency of the resistivity. A heat-treat curve for each melt is developed at Hamilton and is made available as a guide in regulating TCR. Sizes Evanohm® R is available from Hamilton Precision Metals as foil and strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) and in widths up to 12.0”

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

CP Titanium is selected for its favorable strength to weight ratio and excellent corrosion resistance. Two levels of purity permit a choice of finish strength. The alloy can be formed from the annealed temper. Severe forming may be aided by an intermediate stress relief at 1000°F. Stress relieving may be appropriate after severe cold forming to remove residual stresses. Welding should be performed with inert gas shielded arc or spot welding. Welding with active gases, coatings, or fluxes must be avoided to prevent embrittlement. Available Sizes: CP Titanium is available from Hamilton Precision Metals as strip product from 0.0005” to 0.025” (0.0127 mm to 0.635 mm) and widths up to 12.0” (304.8 mm). A foil product is available as thin as 0.000085” (0.002159 mm) and widths of 4.0” (101.6 mm) maximum. The material conforms to ASTM F67, ASTM B265, AMS 4902 and UNS R50250,R50400.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Titanium exhibits a unique combination of properties including excellent corrosion resistance, high temperature resistance, and outstanding strength to weight ratios. Titanium is produced as commercially pure or alloyed. Commercially pure titanium is typically used in implantable medical applications whereas the titanium alloys are produced with the addition of vanadium or aluminum for applications such as aerospace. Hamilton Precision Metals processes strip and foil products in Titanium CP (Grade 1, Grade 2, Grade 4) and Titanium 3Al-2.5V (Grade 9).

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Phosphor Bronze A is a Copper base spring material with a good combination of strength, formability, and corrosion resistance. The material is suitable for use in certain contact springs and diaphragms. The alloy has good formability up to moderate strength. It can be soldered, silver brazed, and resistance welded. Available Sizes: Phosphor Bronze A is available from Hamilton Precision Metals as strip products in thicknesses from 0.001” to 0.020” (0.0254 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B 103 and UNS C51000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Shunt Manganin is a Copper-Manganese resistance alloy used for shunts in various high current applications. The alloy has a low temperature coefficient of resistivity with peak resistance at about 50°C. The thermal EMF vs. Copper is very low. The alloy can be easily formed from the annealed temper.The maximum recommended operating temperature in air is 200°F. Available Sizes: Shunt Manganin is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005 to 0.053” (0.0127 mm to 1.346 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000100” (0.00254 mm) in widths of 4.0” (101.6 mm) maximum.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Cu-Ni 715 is a copper-nickel alloy that is resistant to corrosion in sea water. The alloy has good fatigue strength and relatively high thermal conductivity. This alloy is used mainly for flexible metal foil heaters. The alloy is readily formed in the annealed temper, and can be joined by the standard welding, brazing and soldering processes. Available Sizes: Cu-Ni 715 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12” (304.8 mm). The material conforms to ASTM B122 and UNS C71500.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Copper 102 is an oxygen-free copper with extremely high electrical conductivity and good formability. These characteristics make it particularly useful for electrical connectors. Copper 102 can be deep-drawn from the annealed temper.It is corrosion resistant in normal atmosphere and water. A thin adherent oxide film forms at elevated temperatures which prevents particle contamination and enhances glass to metal seals. The Copper 102 can be readily soldered and brazed. The absence of oxygen makes welds free of inclusions. Available Sizes: Copper 102 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM B 152 and UNS C10200. It is also available in thickness less than 0.0005” (0.0127 mm) in widths up to 4.000” (101.6 mm) maximum.

Request for a quoteResults for

Precision strip - Import exportNumber of results

63 ProductsCountries

Company type

Category

- Steel & Metals (36)

- Cold rolled steel strips (7)

- Measurement - Equipment & Instruments (5)

- Sensors (2)

- Sheet metal and strips, tinplate (2)

- Steel sheets and strips (2)

- Copper sheets and bands (1)

- Display units for exhibitions (1)

- Pipes and tubes, aluminium (1)

- Pipes and tubes, stainless steel (1)

- Shearing machine tools (1)

- Stainless steels (1)

- Steels and metals - machining (1)